A method for preparing graphene/polymer ordered micro-nano composite fibers by magnetic spinning

A technology of micro-nano fibers and composite fibers, which is used in the preparation of spinning solutions, single-component synthetic polymer rayon, chemical characteristics of fibers, etc. hidden dangers and other problems, to achieve the effect of easy popularization and application, uniform diameter distribution, and low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing graphene / polymer micro-nano fibers by magnetic spinning, comprising the following steps:

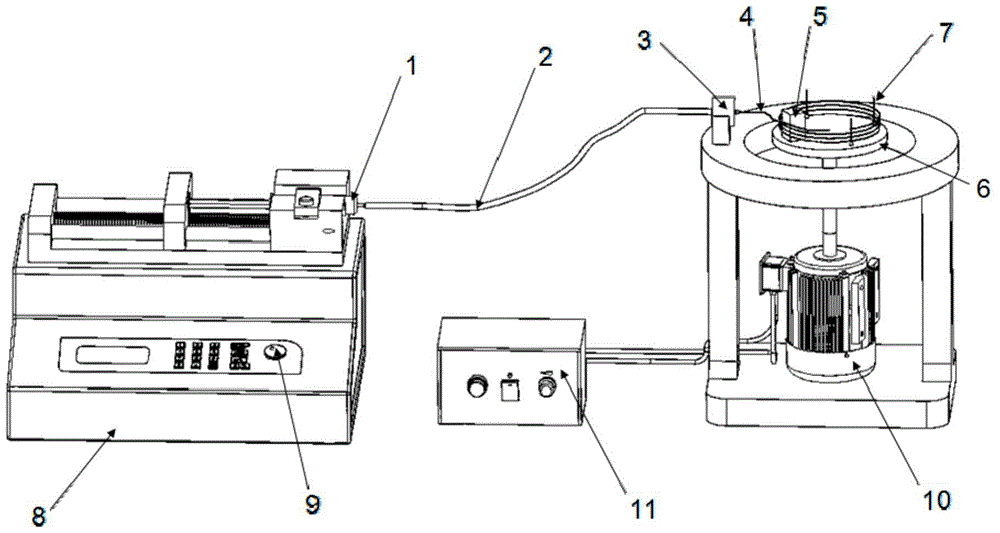

[0025] (1) The construction of the magnetic spinning device: the magnetic spinning device is as follows: figure 1 As shown, it includes a feeding device that can control the feeding rate, a spinning nozzle 4, a nozzle driving mechanism and a spinning receiving device, and the spinning receiving device includes a horizontally arranged collecting disc 6, and the collecting disc 6 The center of the bottom circle is connected with the output shaft of the DC brushless motor 10, and the DC brushless motor 10 is electrically connected to the power supply and the motor controller 11 for controlling the motor speed. The upper surface of the collecting disc 6 is symmetrical about the central axis of the disc. A plurality of vertical pillars are set, and the vertical pillars are 4, of which 1 is a permanent magnet 5, and 3 are metal fine needles 7, and the spinning noz...

Embodiment 2

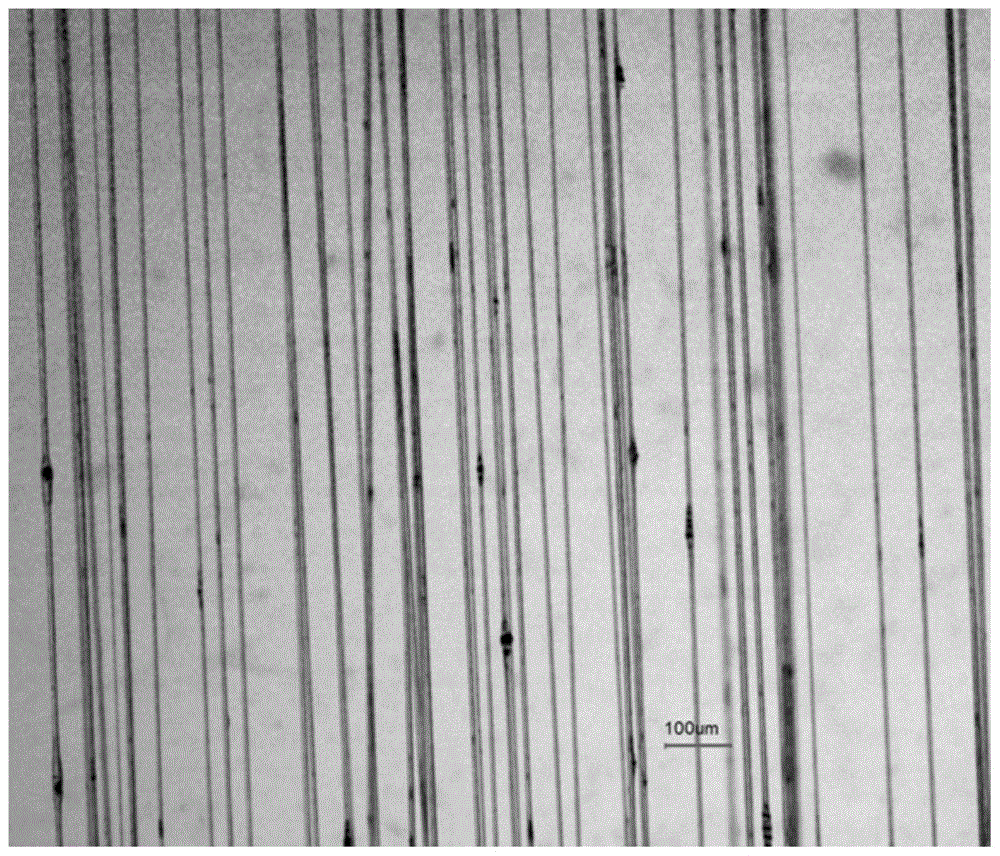

[0029] The Graphene / polymer ordered micro-nano composite fiber containing magnetic nanoparticles obtained in Example 1 is subjected to post-treatment: the ordered Graphene / polymer micro-composite fiber containing magnetic nanoparticles obtained in step (3) of Example 1 Put the nanocomposite fiber into the mixed solution of sulfuric acid and nitric acid with a volume ratio of 3:1 and immerse and oxidize it. The oxidation temperature is 80°C for 48 hours. ℃ dry. Ordered graphene / polymer micro-nano composite fibers without magnetic particles can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com