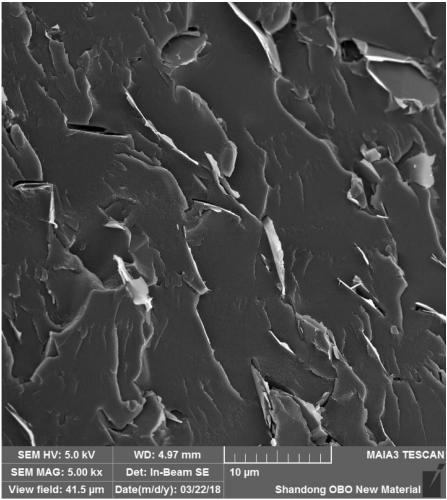

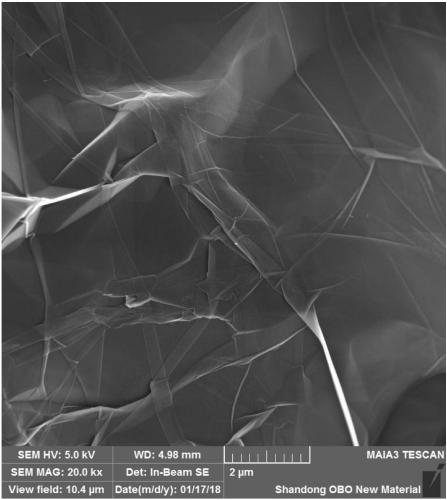

Coating of water-based graphene static-conducting floor paint, water-based graphene static-conducting floor paint and preparation method thereof

A floor paint and graphene layer technology, which is applied in the direction of conductive paint, coating, anti-corrosion paint, etc., can solve the problems of poor dispersion of floor paint products, the impact of floor paint aesthetics, and difficult control of resistance value, etc., to achieve water resistance Good performance, good adhesion, enhanced anti-static ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

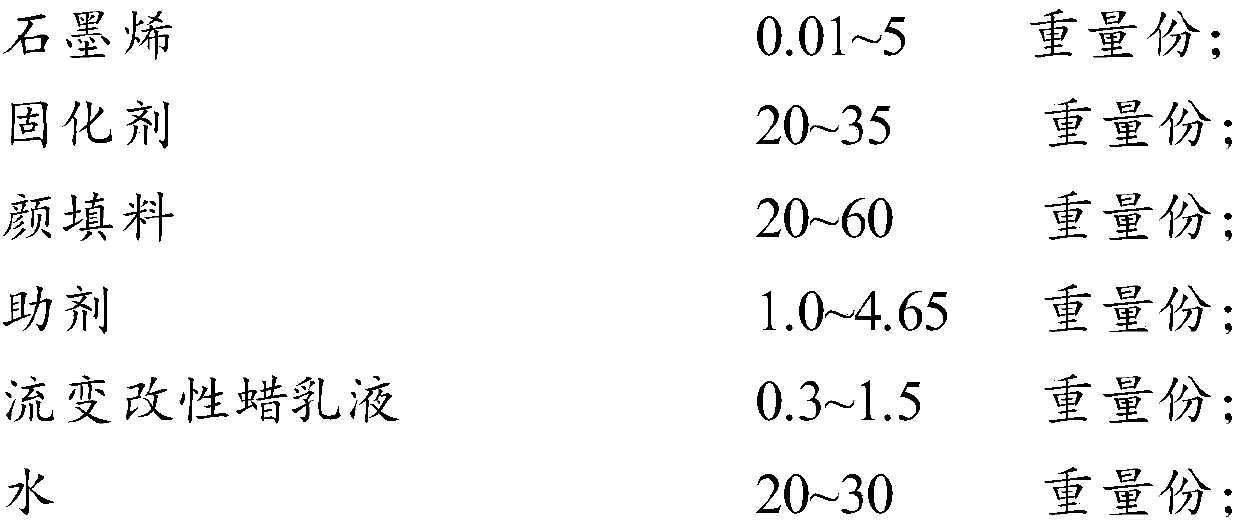

[0112] The present invention also provides a kind of preparation method of water-based floor paint, comprises the following steps:

[0113] A component preparation steps:

[0114] 1) After mixing water, curing agent, a part of additives and rheology-modified wax emulsion for the first time, adding graphene and mixing again to obtain a mixture;

[0115] 2) adding pigments and fillers to the mixture obtained in the above steps for dispersion and grinding to obtain a mixed slurry;

[0116] 3) Continue mixing after adding the remaining additives to the mixed slurry obtained in the above steps to obtain component A;

[0117] B component preparation steps:

[0118] Stir and mix epoxy resin E51 and propylene glycol methyl ether acetate and let it stand to obtain component B;

[0119] Described water-based floor paint comprises A component and B component;

[0120] The additives include one or more of dispersants, wetting and leveling agents, defoamers and rheological additives. ...

Embodiment 1

[0160] A component preparation:

[0161]Put 23 parts of curing agent in the reaction kettle, slowly add 20 parts of deionized water to emulsify while stirring, and form a uniform water emulsion, stir at a low speed for 5 minutes, the stirring speed is 350-600r / min, do not let the material splash; the water is added Finally, put in 0.35 parts of dispersant, 0.15 parts of wetting and leveling agent, 0.15 parts of defoamer, and 0.35 parts of rheology-modified wax emulsion, stir at low speed for 5 minutes, and stir at a speed of 350-600r / min. Do not let the material splash; after that Put in 0.01 parts of graphene, stir ultrasonically for 15 minutes, and the stirring speed is 200-400r / min, do not let the material splash; after the dispersion is uniform, slowly add 45 parts of other pigments and fillers, be careful not to cause serious dust and powder accumulation, use a small amount of water Rinse the powder on the cylinder wall; disperse at high speed for 10-15 minutes, then ente...

Embodiment 2

[0176] A component preparation:

[0177] Put 28 parts of curing agent in the reaction kettle, slowly add 25 parts of deionized water to emulsify while stirring, and form a uniform water emulsion, stir at a low speed for 5 minutes, the stirring speed is 350-600r / min, do not let the material splash; the water is added Finally, put in 0.75 parts of dispersant, 0.21 parts of wetting and leveling agent, 0.19 parts of defoamer, and 0.8 parts of rheology-modified wax emulsion, stir for 5 minutes at low speed, and the stirring speed is 350-600r / min. Do not let the material splash; after that Put in 0.03 parts of graphene, stir ultrasonically for 15 minutes, the stirring speed is 200-400r / min, do not let the material splash; after the dispersion is uniform, slowly add 45 parts of other pigments and fillers, be careful not to cause serious dust and powder accumulation, use a small amount of water Rinse the powder on the cylinder wall; disperse at high speed for 10-15 minutes, then enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com