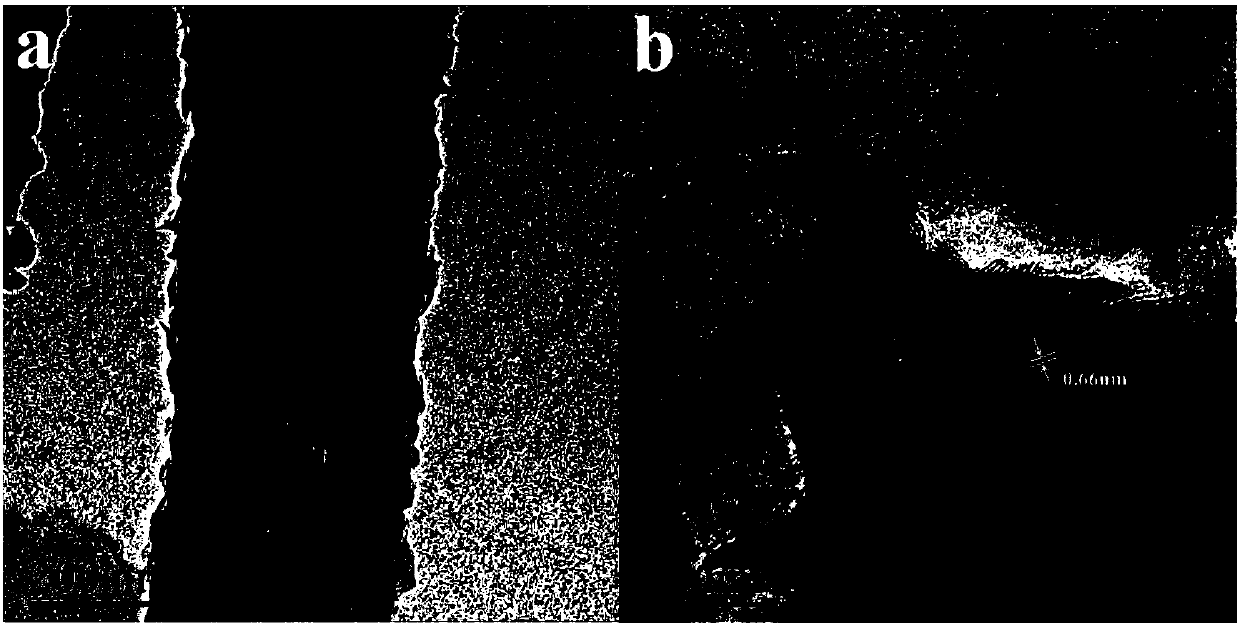

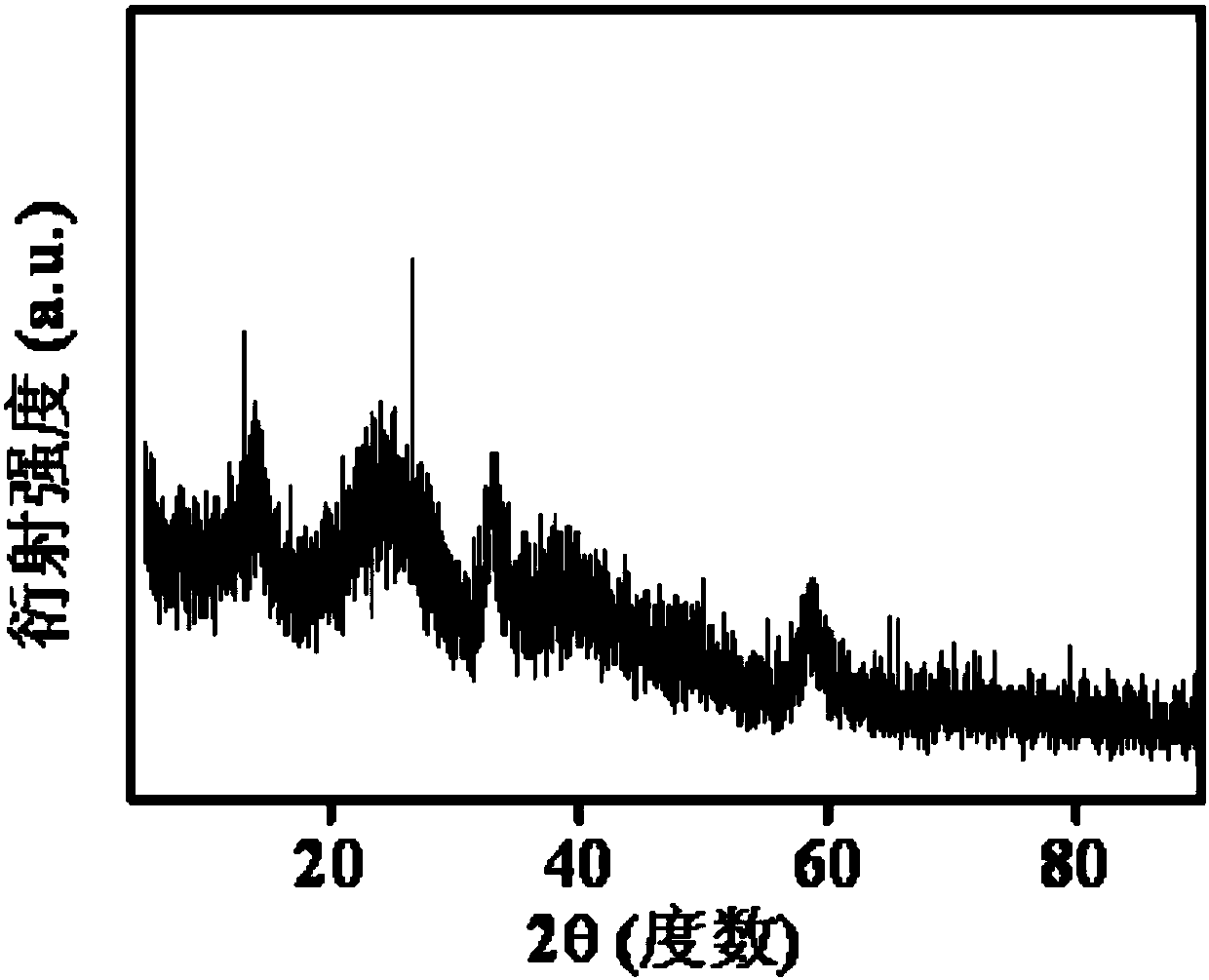

Nitrogen doped carbon nanofiber/molybdenum disulfide composite and preparation method and application thereof

A nanofiber and molybdenum disulfide technology, applied in the field of energy storage materials, can solve the problems of easy structure collapse, poor conductivity of molybdenum sulfide, reduced cycle performance and rate performance, and achieve the effects of inhibiting agglomeration, easy operation, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 0.8g polymethyl methacrylate in 10ml DMF, stir for 12h to obtain polymethyl methacrylate spinning stock solution, add it to the syringe, and inject it at a speed of 0.1mm / min and a voltage of 15kV 1. Under the condition that the distance between the needle of the syringe and the receiving plate is 15 cm, electrospinning is carried out to obtain a polymethyl methacrylate nanofiber film.

[0029] (2) 1.01g pyrrole is mixed with 1mol / L hydrochloric acid aqueous solution to obtain 500ml pyrrole solution, 3.24g ferric chloride trihydrate is mixed with 1mol / L hydrochloric acid aqueous solution to obtain 500ml ferric chloride solution, step (1) 0.5g of the polymethyl methacrylate nanofiber membrane in 500ml pyrrole solution was soaked for 30min, and under ice-water bath conditions, 500ml of ferric chloride solution was added dropwise to the pyrrole solution, and the mixed solution was heated at zero Under the condition of reaction for 12 hours, the polypyrrole / pol...

Embodiment 2

[0036] (1) Dissolve 0.8g polymethyl methacrylate in 10ml DMF, stir for 12h to obtain polymethyl methacrylate spinning stock solution, add it to the syringe, and inject it at a speed of 0.1mm / min and a voltage of 15kV 1. Under the condition that the distance between the needle of the syringe and the receiving plate is 15 cm, electrospinning is carried out to obtain a polymethyl methacrylate nanofiber membrane.

[0037] (2) 1.01g pyrrole is mixed with 1mol / L hydrochloric acid aqueous solution to obtain 500ml pyrrole solution, 3.24g ferric chloride trihydrate is mixed with 1mol / L hydrochloric acid aqueous solution to obtain 500ml ferric chloride solution, step (1) 0.3g of the polymethyl methacrylate nanofiber membrane in 500ml pyrrole solution was soaked for 30min, and under ice-water bath conditions, 500ml of ferric chloride solution was added dropwise to the pyrrole solution, and the mixed solution was heated at zero Under the condition of reaction for 12 hours, the polypyrrole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com