Preparation method of organic/inorganic hybridization nano super-hydrophobic fiber film

A super-hydrophobic, fibrous membrane technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of human body and ecological environment hazards, high price, etc., and achieve the effect of low price, wide application and uniform diameter distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The precursor solution of polymeric inorganic substances was prepared by sol-gel technology: a polyvinyl alcohol (PVA) solution with a mass fraction of 10% was prepared, heated to 90°C in a water bath and continuously stirred with a magnetic stirrer for 4 hours to Mix well. The molar ratio of ethyl orthosilicate: water: zinc acetate: phosphoric acid is 1:1.5:0.3:0.02 to prepare a mixed solution of TEOS and zinc acetate, and stir at room temperature for 4 hours. Then mix it with the PVA solution at a mass ratio of 1:1 to obtain an electrospinning precursor solution.

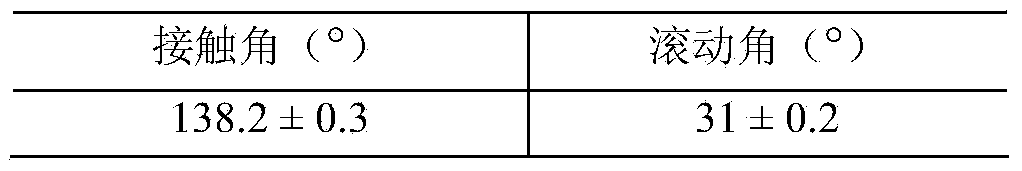

[0029] (2) Electrospinning to obtain organic-inorganic hybrid fibers: pump the precursor solution into the syringe, apply a high voltage of 20KV at the nozzle through a high-voltage DC power supply, and place the syringe on a micro-injection pump, and adjust the injection speed to 2mL / hour, the receiving distance is set to 20cm. A fibrous membrane was obtained on a receiver lined with aluminum foil....

Embodiment 2

[0032](1) The precursor solution of polymeric inorganic substances was prepared by sol-gel technology: a polyvinylpyrrolidone (PVP) solution with a mass fraction of 10% was prepared, heated to 90°C in a water bath, and continuously stirred with a magnetic stirrer for 4 hours to Mix well. The molar ratio of ethyl orthosilicate: water: zinc acetate: phosphoric acid is 1:1.5:0.3:0.02 to prepare a mixed solution of TEOS and zinc acetate, and stir at room temperature for 4 hours. Then mix it with the PVA solution at a mass ratio of 1:1 to obtain an electrospinning precursor solution.

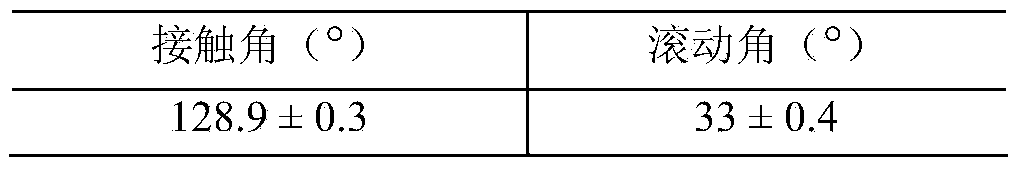

[0033] (2) Electrospinning to obtain organic-inorganic hybrid fibers: pump the precursor solution into the syringe, apply a high voltage of 15KV at the nozzle through a high-voltage DC power supply, and place the syringe on a micro-injection pump, and adjust the injection speed to 2mL / hour, the receiving distance is set to 15cm. A fibrous membrane was obtained on a receiver lined with aluminum fo...

Embodiment 3

[0037] (1) The precursor solution of polymeric inorganic substances was prepared by sol-gel technology: a polyvinyl alcohol (PVA) solution with a mass fraction of 10% was prepared, heated to 85°C in a water bath and continuously stirred with a magnetic stirrer for 4 hours to Mix well. The molar ratio of ethyl orthosilicate: water: zinc acetate: phosphoric acid is 1:1.5:0.3:0.02 to prepare a mixed solution of TEOS and zinc acetate, and stir at room temperature for 4 hours. Then mix it with the PVA solution at a mass ratio of 1:1 to obtain an electrospinning precursor solution.

[0038] (2) Electrospinning to obtain organic-inorganic hybrid fibers: pump the precursor solution into the syringe, apply a high voltage of 20KV at the nozzle through a high-voltage DC power supply, and place the syringe on a micro-injection pump, and adjust the injection speed to 2mL / hour, the receiving distance is set to 20cm. A fibrous membrane was obtained on a receiver lined with aluminum foil....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com