Material receiving mechanism for conveying pipe fitting

A technology for conveying pipes and pipe fittings, which is applied in the direction of conveyors, conveyor objects, feeding devices, etc. It can solve the problems of bent pipes or pipe fittings being twisted and damaged, easy to insert under the rear swing arm, messy, etc., to achieve neat placement , to avoid the effect of pipe breaking and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

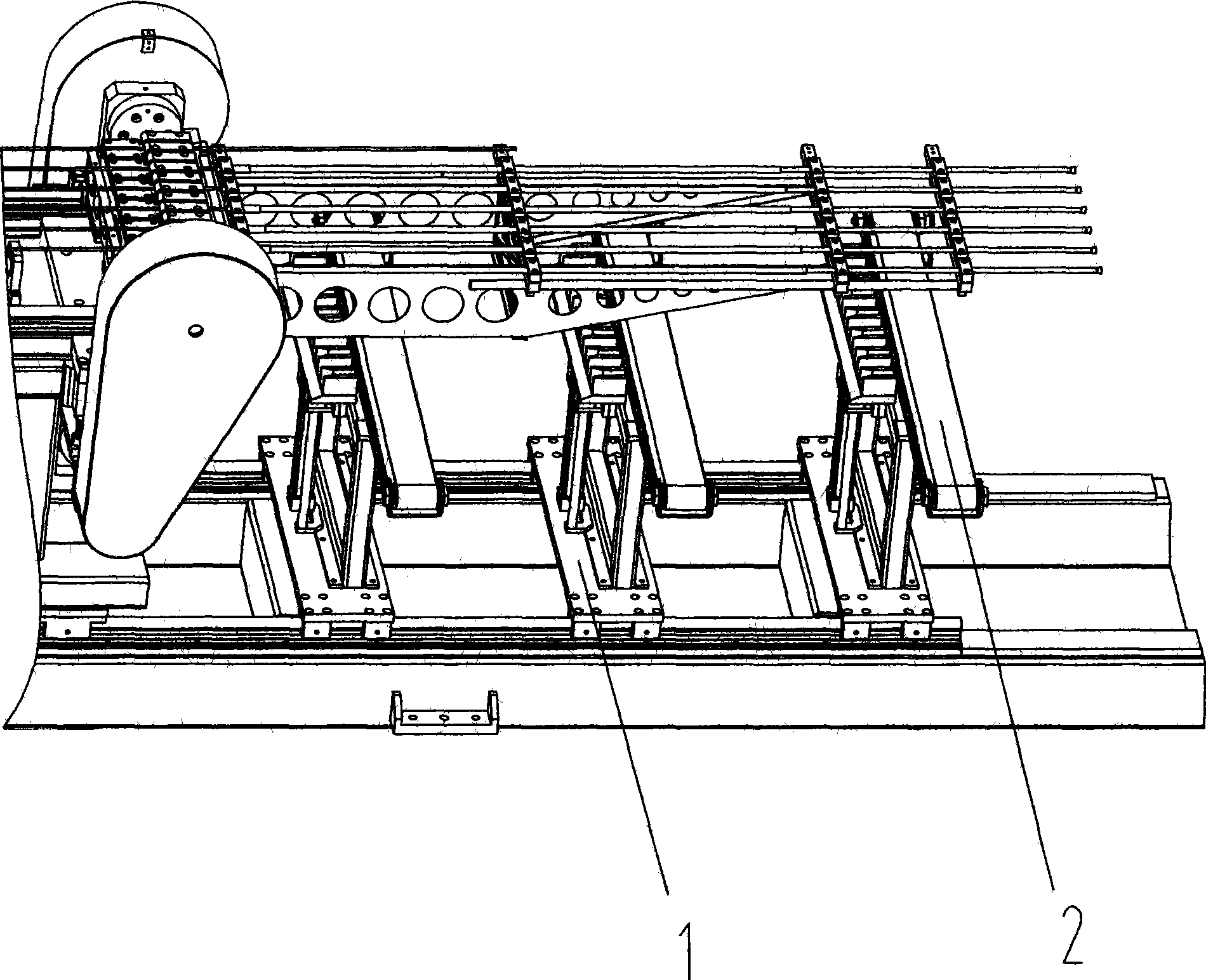

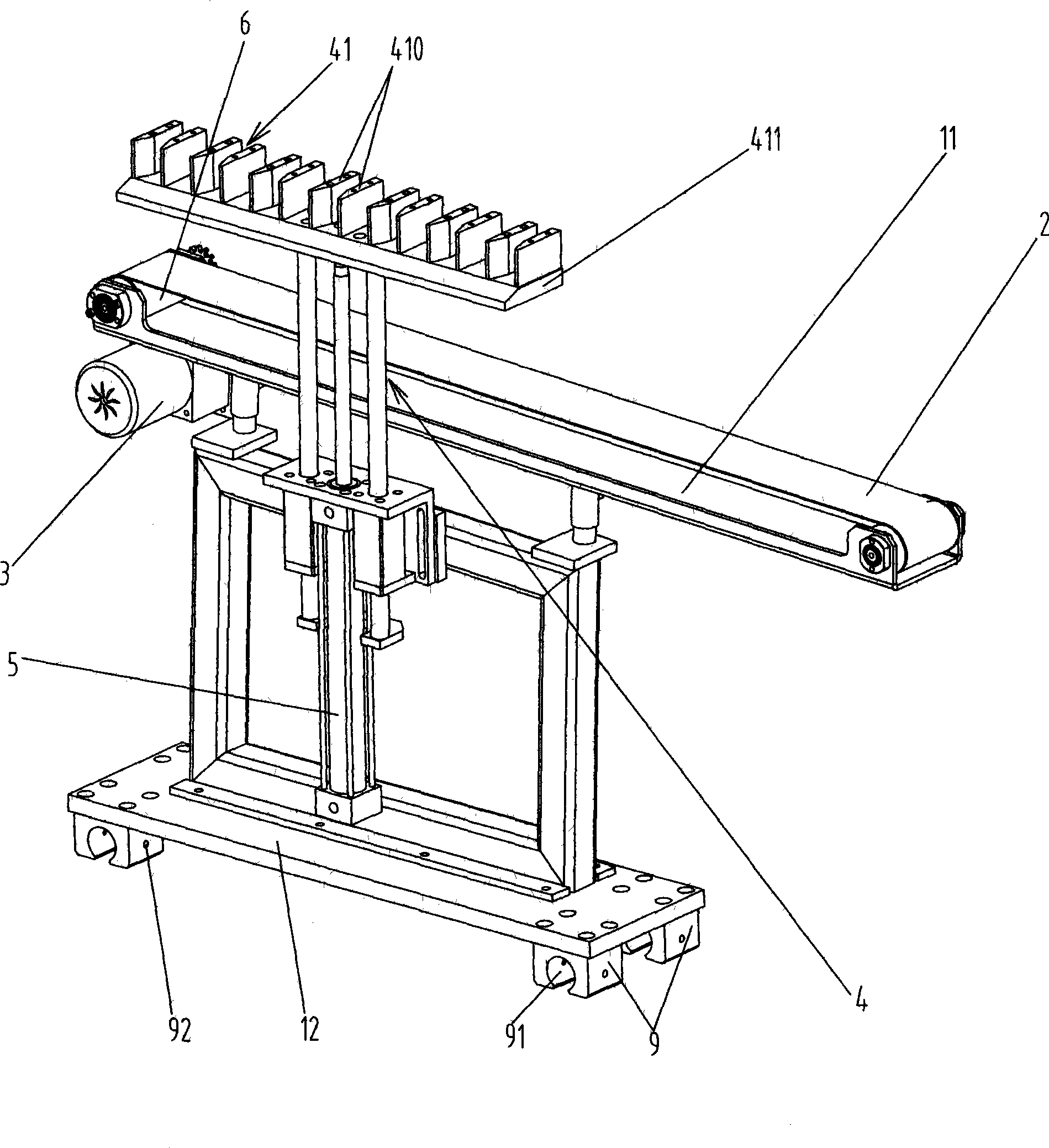

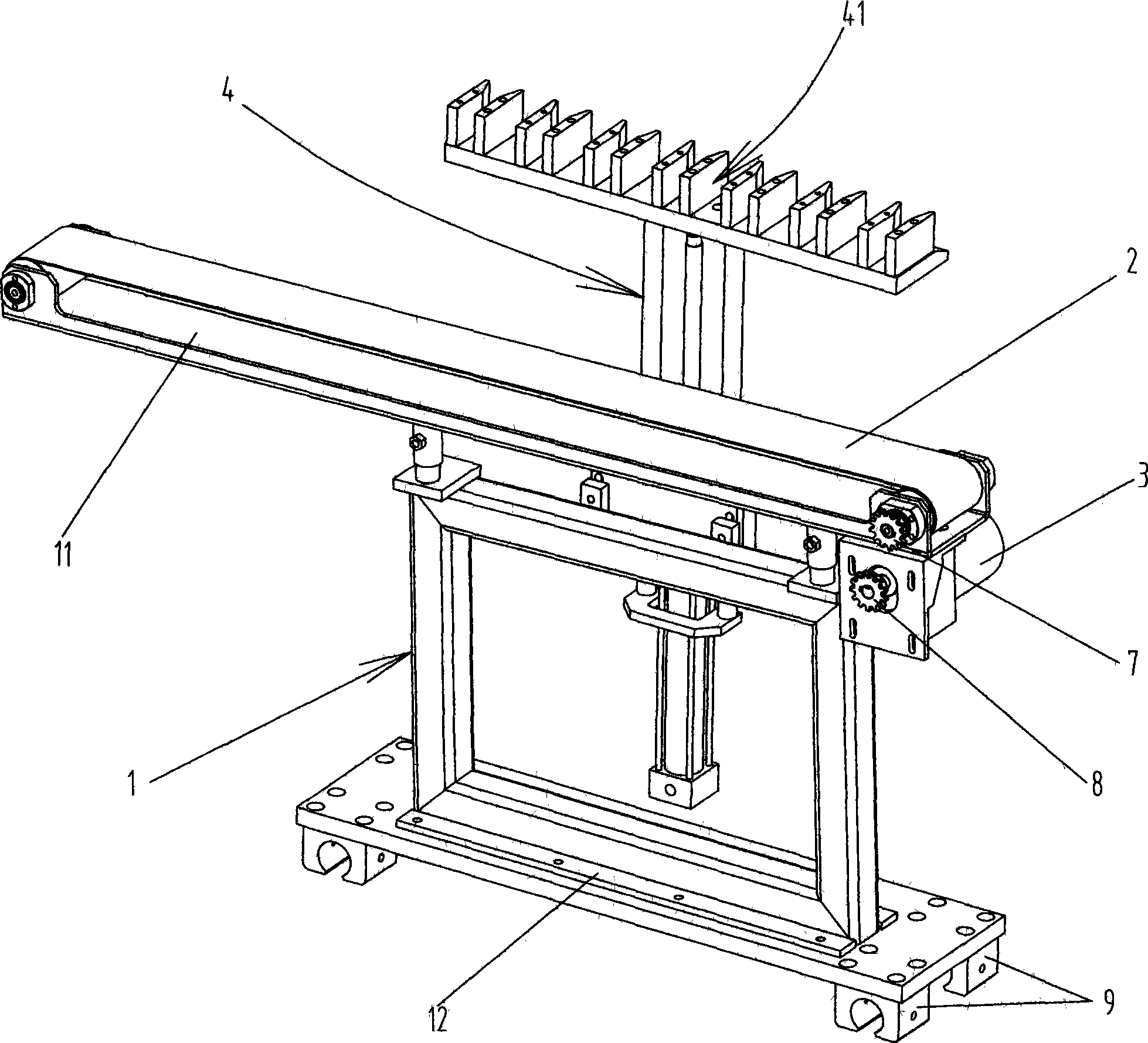

[0018] As shown in the figure, the material receiving mechanism for conveying pipe fittings includes a conveyor belt 2 installed on a bracket 1 and a first drive 3 that drives the conveyor belt to rotate. One side of the conveyor belt 2 is provided with a The pipe fittings are sent to the material receiving frame 4 on the conveyor belt 2, the upper end of the material receiving frame 4 is provided with a plurality of clamping positions 41 for placing the pipe fittings, and the second driving member 5 for promoting its movement is installed under the material receiving frame 4, the present invention Among them, the upper end of the material receiving frame 4 is provided with a material receiving plate 411, and the clamping position 41 is a material receiving trough formed by two vertical baffles 410 and the material receiving plate 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com