Novel shading rubber belt

A light-shielding tape, a new technology, applied in optics, adhesives, nonlinear optics, etc., can solve problems such as overflowing glue, limited thickness specifications, and affecting the quality of the light-emitting surface of the backlight module, achieving uniform texture and avoiding glue overflowing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

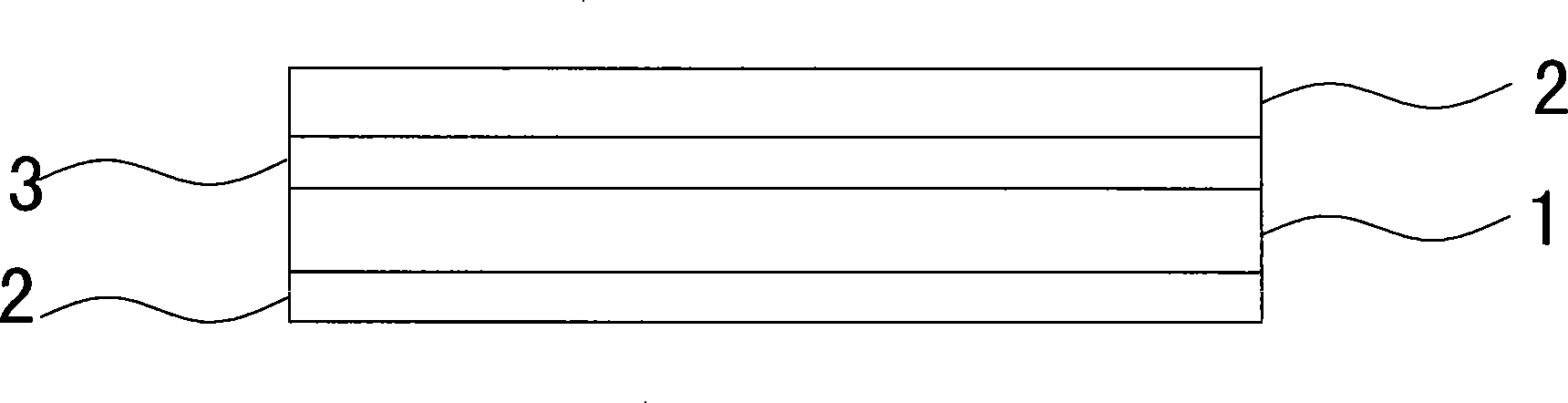

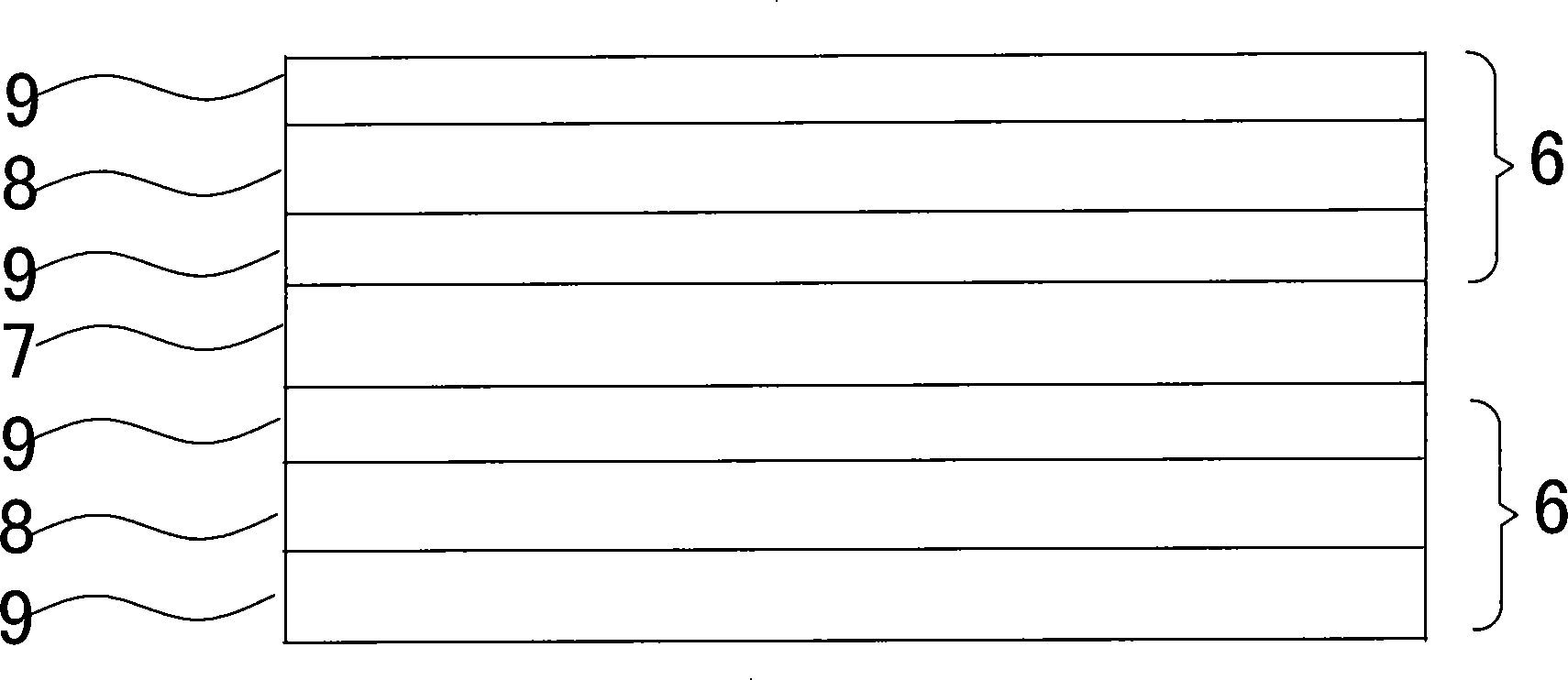

[0021] Embodiment one: see attached image 3 Shown, a kind of thickness is the light-shielding double-sided adhesive tape of 0.15mm, comprises light-shielding layer 7 and adhesive layer 6, and described light-shielding layer 7 selects black PET film for use, and its thickness is 0.05mm (Japan Toray X30), adhesive Layer 6 is made of double-sided tape, which is composed of base material layer 8 and adhesive layer 9 on both sides, the thickness of which is 0.05mm (TESA4972), and the two sides of the black PET film are respectively compounded with a layer of double-sided adhesive tape under heating conditions. Tape layers, thereby constituting a light-shielding tape with a thickness of 0.15mm.

Embodiment 2

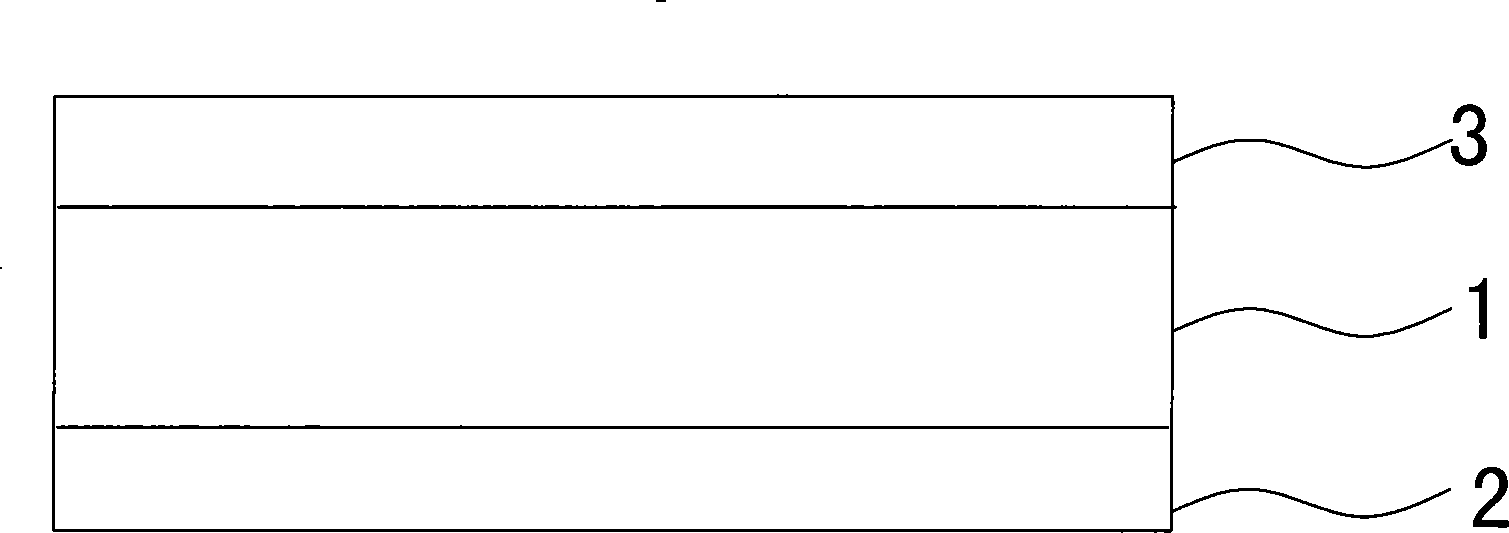

[0022] Embodiment two: see attached Figure 4 As shown, a single-sided light-shielding tape with a thickness of 0.13mm and a reflective function is used. The black PET film is used for the light-shielding layer, and its thickness is 0.075mm (Toray X30 in Japan). The adhesive layer is double-sided tape, and its thickness is 0.055mm. mm (Sekisui #550P5BW), the tape has a white reflective layer, and a layer of double-sided tape is compounded on one side of the black PET film under heating conditions to form a light-shielding single-sided tape with a thickness of 0.13mm and a reflective function. .

Embodiment 3

[0023] Embodiment three: see attached image 3 As shown, a light-shielding double-sided tape with a thickness of 0.085mm, the light-shielding layer is made of black PET film with a thickness of 0.025mm (Toray X30 in Japan), and the adhesive layer is made of double-sided tape with a thickness of 0.03mm (3M9019 ), compound a layer of double-sided adhesive tape on both sides of the black PET film under heating conditions, thereby forming a light-shielding adhesive tape with a thickness of 0.085mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com