Laminating method and equipment

A technology of laminating equipment and preset time, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems that affect the cleaning of products and work surfaces, are not conducive to product processing, and accelerate the fluidity of glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The horizontal, vertical, inner, outer, and up, down, left, and right described in the present invention are based on the placement of components in the drawings, and do not limit the scope of the present invention.

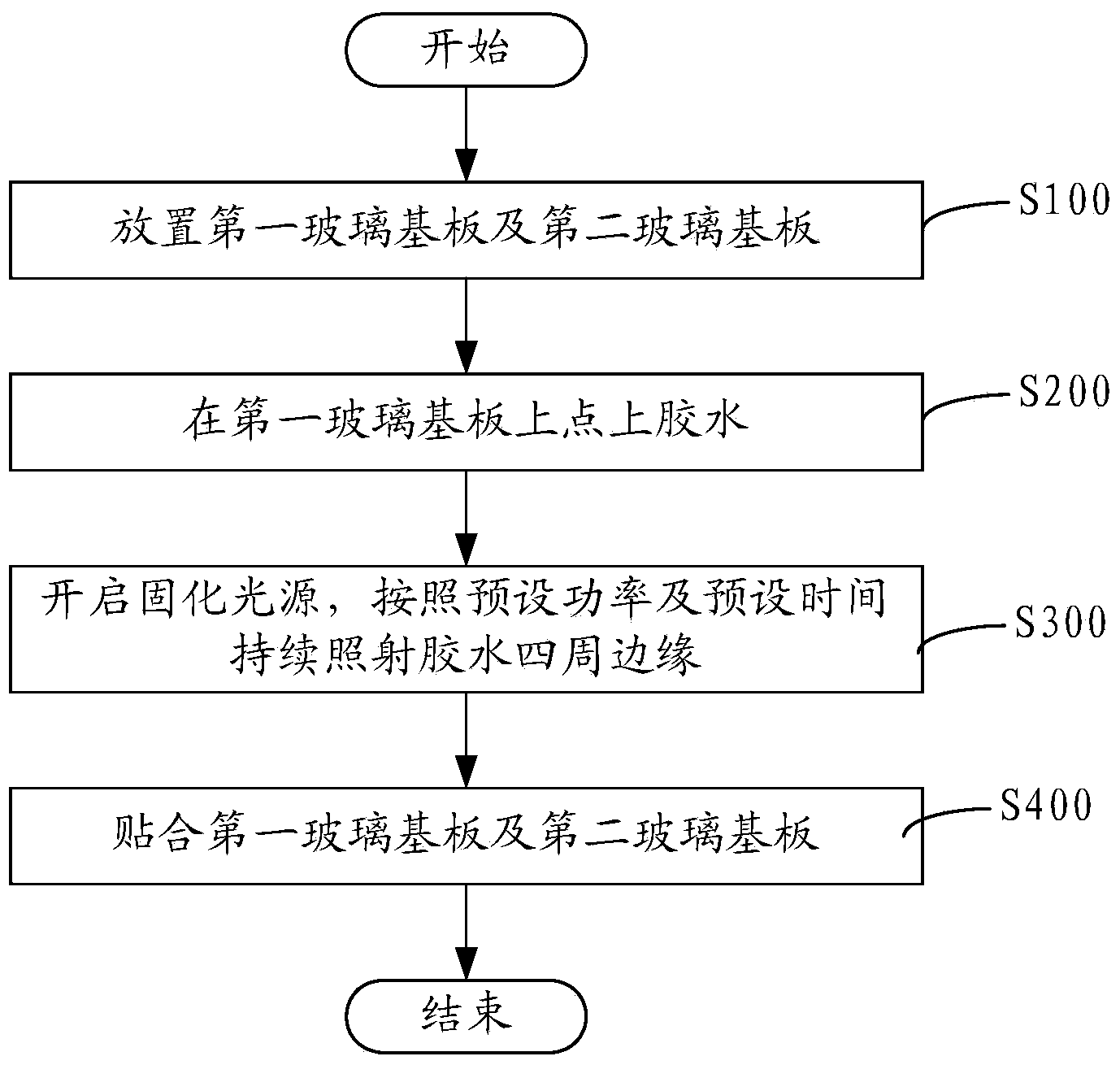

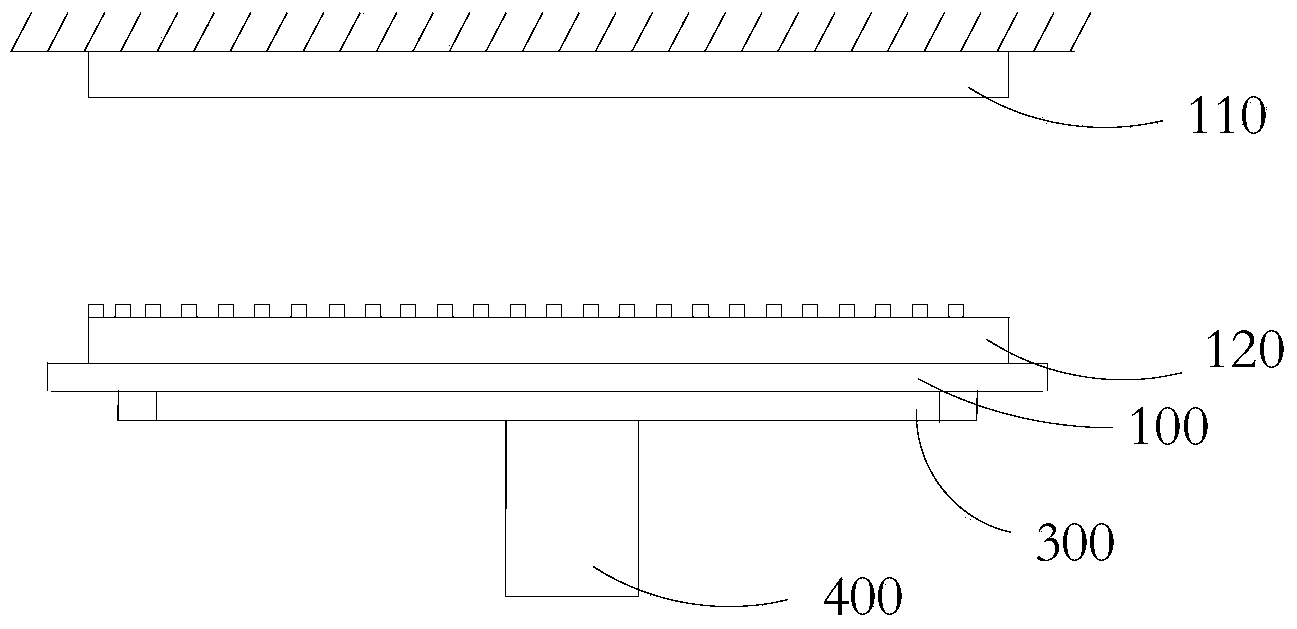

[0023] The present invention proposes a bonding method, with reference to Figure 1~5 , the method consists of the following four steps:

[0024] Step S100, setting a first glass substrate and a second glass substrate.

[0025] Specifically, the glass substrate can be TP (Touch Panel, touch screen), LCM (Liquid Crystal Module, liquid crystal display module), CG (Cover Glass, cover glass) or SG (Sensor Glass, sensing glass); The first glass substrate and the second glass substrate are arranged according to the upper and lower positional relationship. It can be understood that the number of glass substrates may also be multiple and bonded in layers.

[0026] Step S200, dispensing glue on the first glass substrate.

[0027] Specifically, the glue can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com