Solar cell grid line structure, solar cell sheet and solar laminate module

A technology for solar cells and solar cells, applied in the field of solar cells, can solve the problems of high battery cost, overflowing glue, increase the consumption of silver paste and battery cost, etc., and achieve the effect of avoiding glue overflowing and glue leakage and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technology of the present invention is described in detail below in conjunction with accompanying drawing:

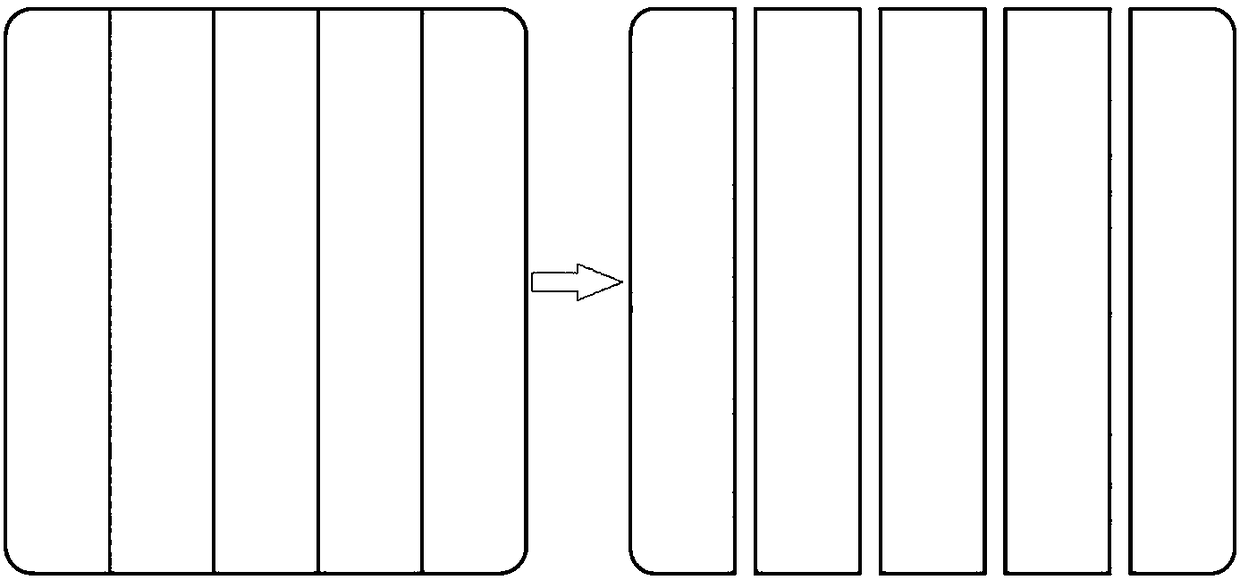

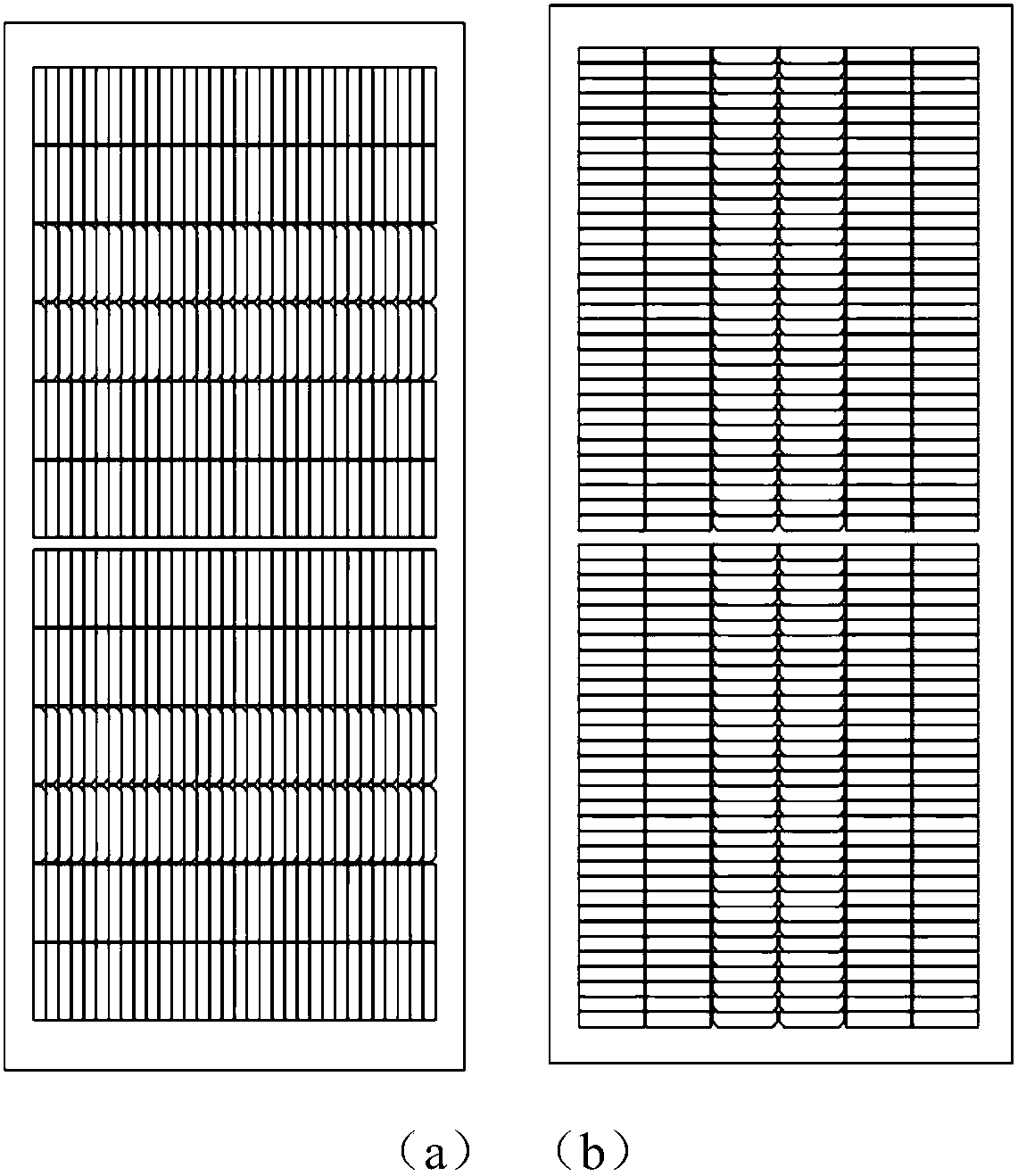

[0061] The battery metallization pattern scheme of the present invention is as follows Figure 8 As shown, it includes main grid lines 2 in the form of a cross grid, and auxiliary grid lines 1 . The busbar 2 is a network structure composed of interlaced thin lines 7, and the thin lines 7 are one or more combinations of straight lines, broken lines and curves; grooves are formed in the grid of the network structure, and the busbar 2 When the conductive glue 6 is applied, part of the conductive glue 6 is filled in the grooves of the grid.

[0062] Such as Figure 8 As shown in (b), the thin lines 7 of the bus bars 2 may be composed of straight lines, broken lines or curved lines. The width of the thin line 7 ranges from 5 microns to 1500 microns, the height of the thin line 7 ranges from 5 microns to 100 microns, the characteristic length of the grid holes r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com