Anti-gluing method for flexible board in groove region of rigid-flexible board

A soft-rigid combination board and soft board technology, which is applied in the direction of assembling printed circuits with electrical components, which can solve the problems of inconvenient operation, limited application of padding on the soft board area, and glue overflowing from the prepreg to the soft board area. , to achieve the effect of ensuring the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0023] In the embodiment of the present invention, a layer of high-temperature-resistant adhesive tape is pasted on the flexible board area. Due to the high-temperature, high-pressure, and high-vacuum environment when the soft-hard board is pressed, the adhesive tape can be closely attached to the cover film, thereby protecting the cover film from flow. Adhesive residue (if there is flow glue flowing on the tape, the tape can be removed later to remove the flow glue).

[0024] The method for anti-sticking of the flexible board in the groove area of the rigid-flex board according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

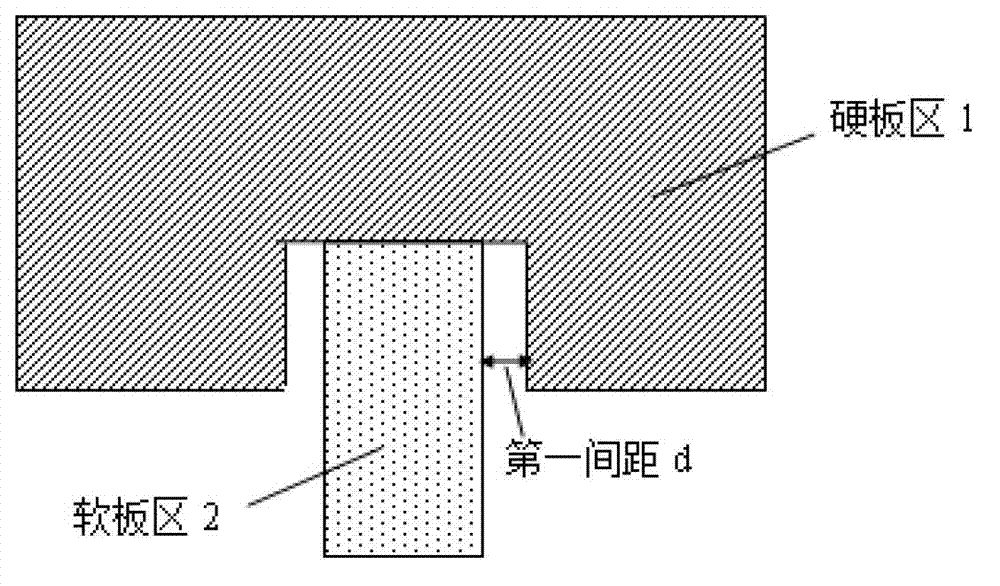

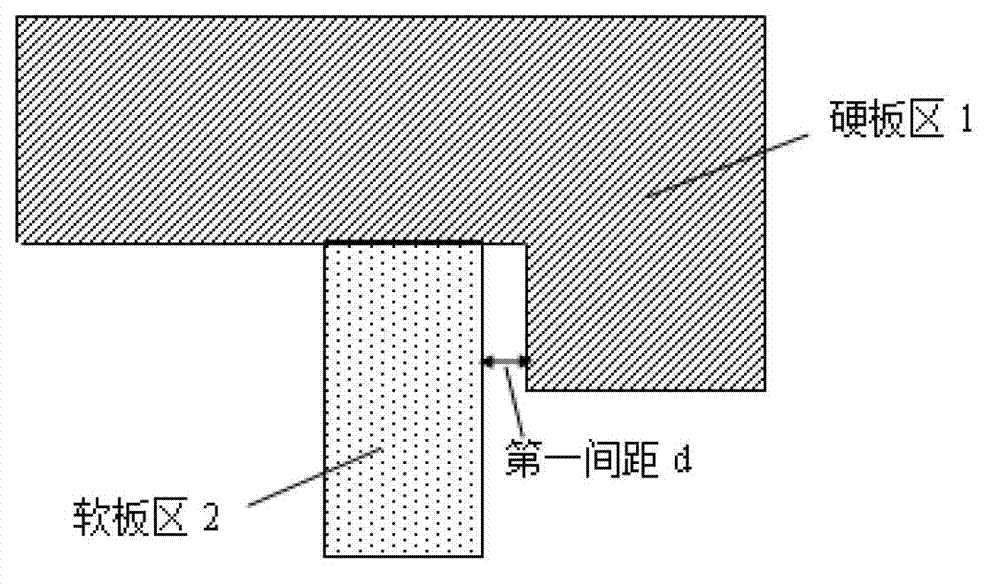

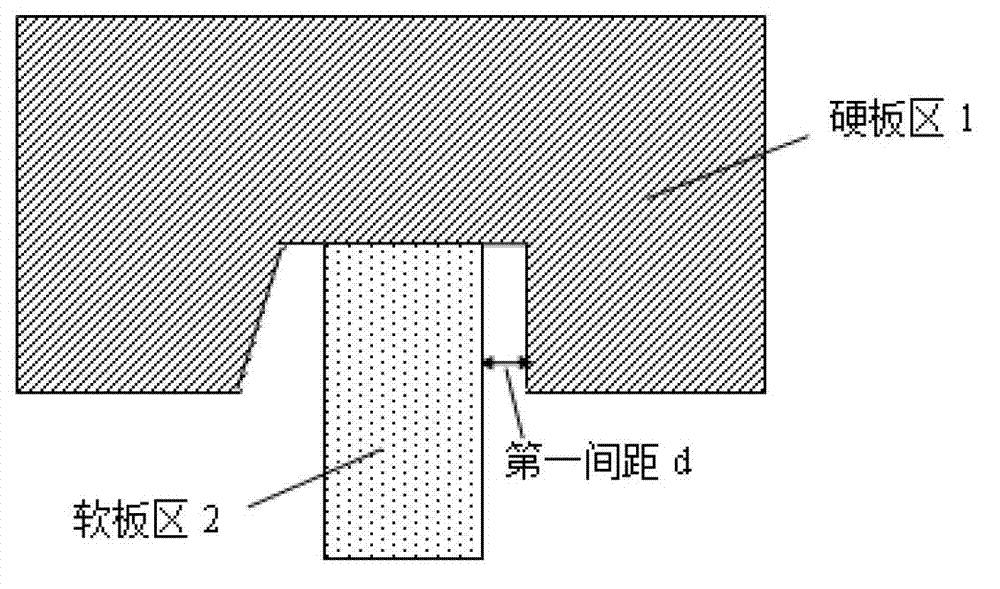

[0025] Figure 4 It schematically shows t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com