Expanded polytetrafluoroethylene film of composite conducting layer and preparation method of expanded polytetrafluoroethylene film

A technology of polytetrafluoroethylene film and composite conductive layer, used in conductive coatings, coatings, devices for coating liquids on surfaces, etc. The olefin coating is easy to fall off and other problems, so as to achieve the effect of good die-cutting, ensuring stability and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

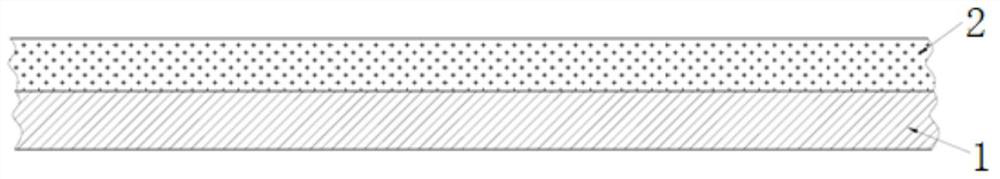

[0025] attached figure 1 The expanded polytetrafluoroethylene film of the composite conductive layer according to the present invention comprises an expanded polytetrafluoroethylene layer 1 and a conductive layer 2; the conductive layer 2 is composited on the expanded polytetrafluoroethylene layer 1 by hot pressing surface.

[0026] Further, the thickness of the expanded polytetrafluoroethylene layer 1 is 0.1mm.

[0027] Further, the conductive layer 2 is graphene.

[0028] The present invention also relates to a method for preparing an expanded polytetrafluoroethylene film of a composite conductive layer, comprising the following steps:

[0029] S1: Stretch the expanded polytetrafluoroethylene layer 1 in one direction, soak it in absolute ethanol, and ultrasonicate it for 30 minutes under the condition of 20KHz at the same time to obtain the substrate, because of its microporous structure on the surface, it has a certain Air permeability, water pressure resistance;

[003...

Embodiment 2

[0034] attached figure 1 The expanded polytetrafluoroethylene film of the composite conductive layer according to the present invention comprises an expanded polytetrafluoroethylene layer 1 and a conductive layer 2; the conductive layer 2 is composited on the expanded polytetrafluoroethylene layer 1 by hot pressing surface.

[0035] Further, the thickness of the expanded polytetrafluoroethylene layer 1 is 0.2 mm.

[0036] Further, the conductive layer 2 is a mixture of graphene and carbon nanotubes.

[0037] The present invention also relates to a method for preparing an expanded polytetrafluoroethylene film of a composite conductive layer, comprising the following steps:

[0038] S1: The expanded polytetrafluoroethylene layer 1 is biaxially stretched, soaked in absolute ethanol, and ultrasonicated at 40KHz for 20 minutes at the same time to obtain the substrate, because of the microporous structure on the surface, it has a certain degree of air permeability capacity, water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com