Anti-wrinkle environmentally friendly hot melt adhesive for film adhesive bags and its preparation method and application

An anti-wrinkle, hot-melt adhesive technology, applied in the direction of adhesive types, adhesives, non-polymer adhesive additives, etc., can solve the problems of overflowing glue, no anti-wrinkle performance of back glue, etc., and achieves a simple process, excellent Die-cutting performance, the effect of reducing the stress in the colloid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In summary, the present invention proposes a method for preparing the wrinkle-resistant environmentally friendly hot-melt adhesive for the film adhesive bag, comprising the following steps:

[0045] S1) prepare each raw material component of the wrinkle-resistant environmental protection hot-melt adhesive of the described membrane back adhesive bag according to weight parts, and the solution polymerized styrene-butadiene rubber, plasticizer DINCH, low Molecular weight polyisobutylene and antioxidants are added to the container and mixed evenly, heated and stirred until each component is completely melted;

[0046] S2) adding PE wax and styrene-modified C5 resin in turn, keeping the same temperature as in step S1 and heating and stirring until completely melted;

[0047] S3) Vacuuming, the vacuum pressure value is -0.7~-1Mpa, stirring and mixing evenly in a vacuum state until the bubbles completely disappear, that is, the anti-wrinkle environmentally friendly hot melt ad...

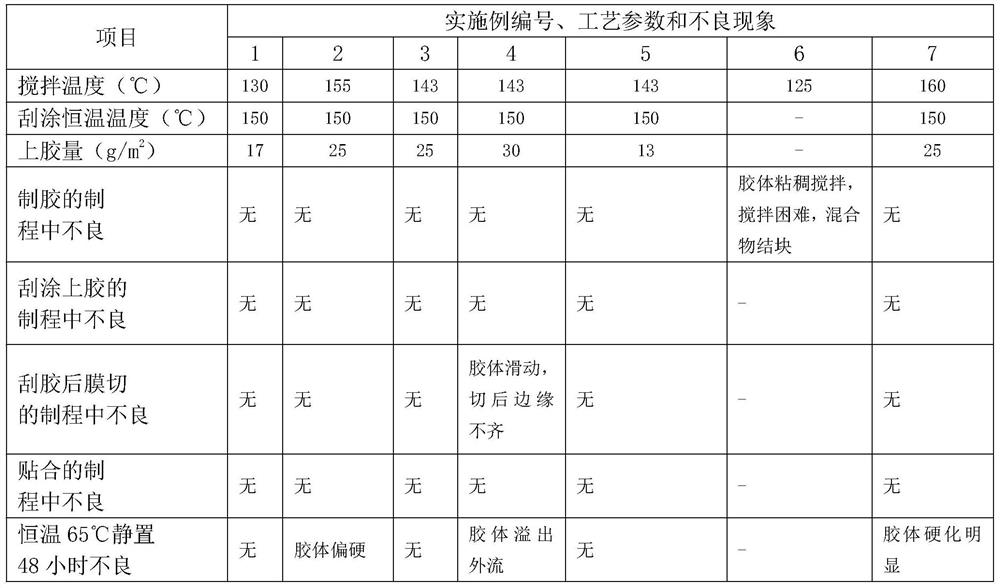

Embodiment 1-7 and comparative example 1-10

[0062] A method for making a film type adhesive bag containing the anti-wrinkle type environmental protection hot melt adhesive of the film type adhesive bag, the specific steps are as follows:

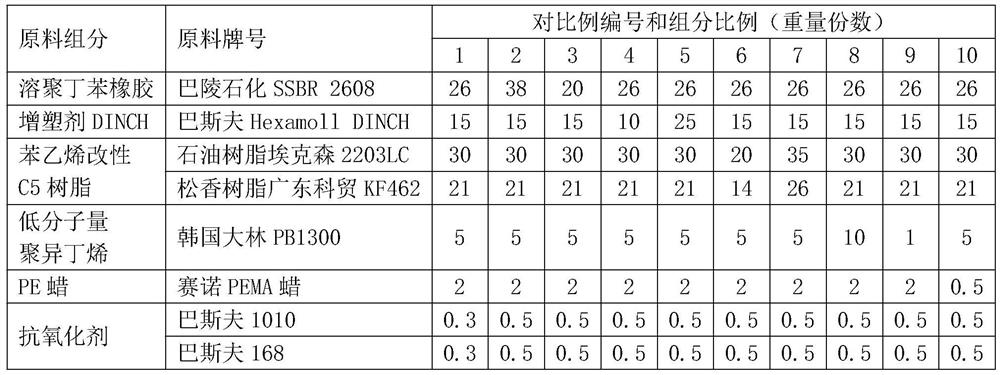

[0063] 1) Prepare each raw material component of the anti-wrinkle type environmental protection hot-melt adhesive of the film type adhesive bag according to parts by weight. The specific grades and ratios of the raw material components of each embodiment are shown in Table 1 below, and the raw materials of each comparative example The specific grades and ratios of the components are shown in Table 2 below;

[0064] 2) Add solution-polymerized styrene-butadiene rubber, plasticizer DINCH, low-molecular-weight polyisobutylene, and antioxidants in each raw material component of the anti-wrinkle environmentally friendly hot-melt adhesive of the prepared film-type adhesive bag to the container Mix evenly, heat and stir until each component is completely melted, the heating temperature value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com