Packaging carton die cutting process and die cutting machine thereof

A die-cutting machine and die-cutting technology, applied in the field of packaging cartons, can solve the problems of unfavorable large-scale production of enterprises, low work efficiency, and redundant scraps, etc., to achieve mass production, convenient disassembly and maintenance, and avoid scraps and scraps. glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

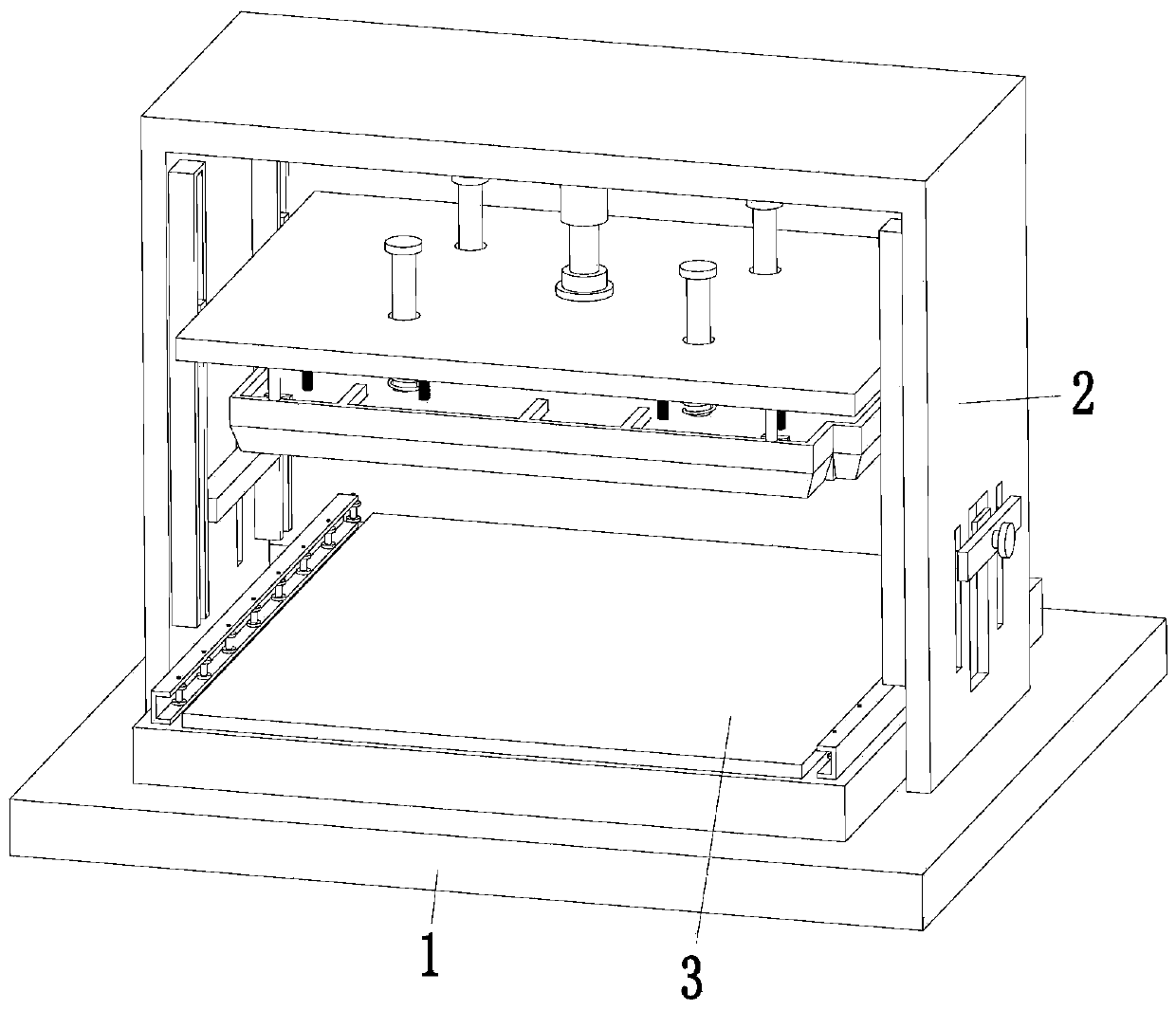

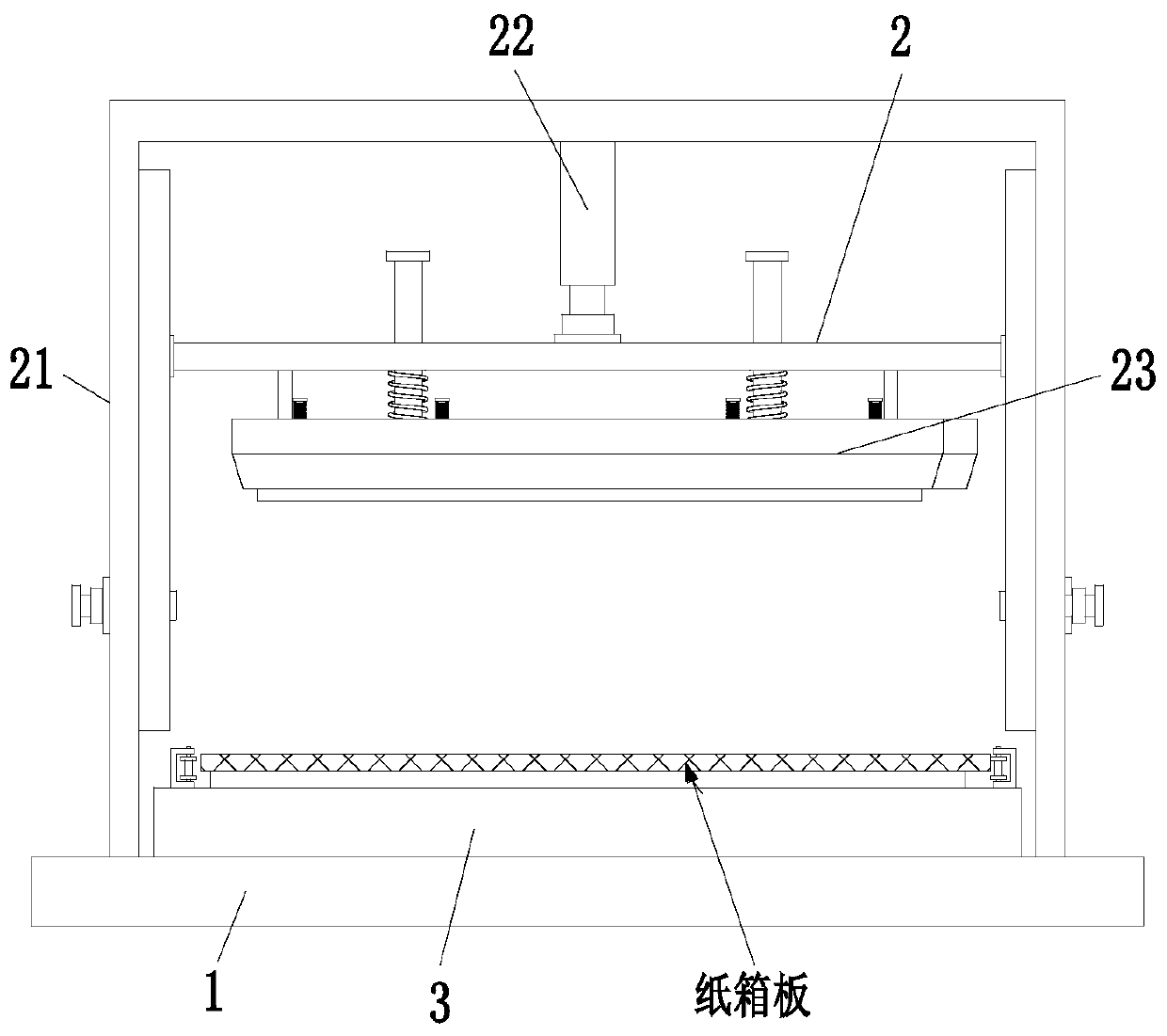

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

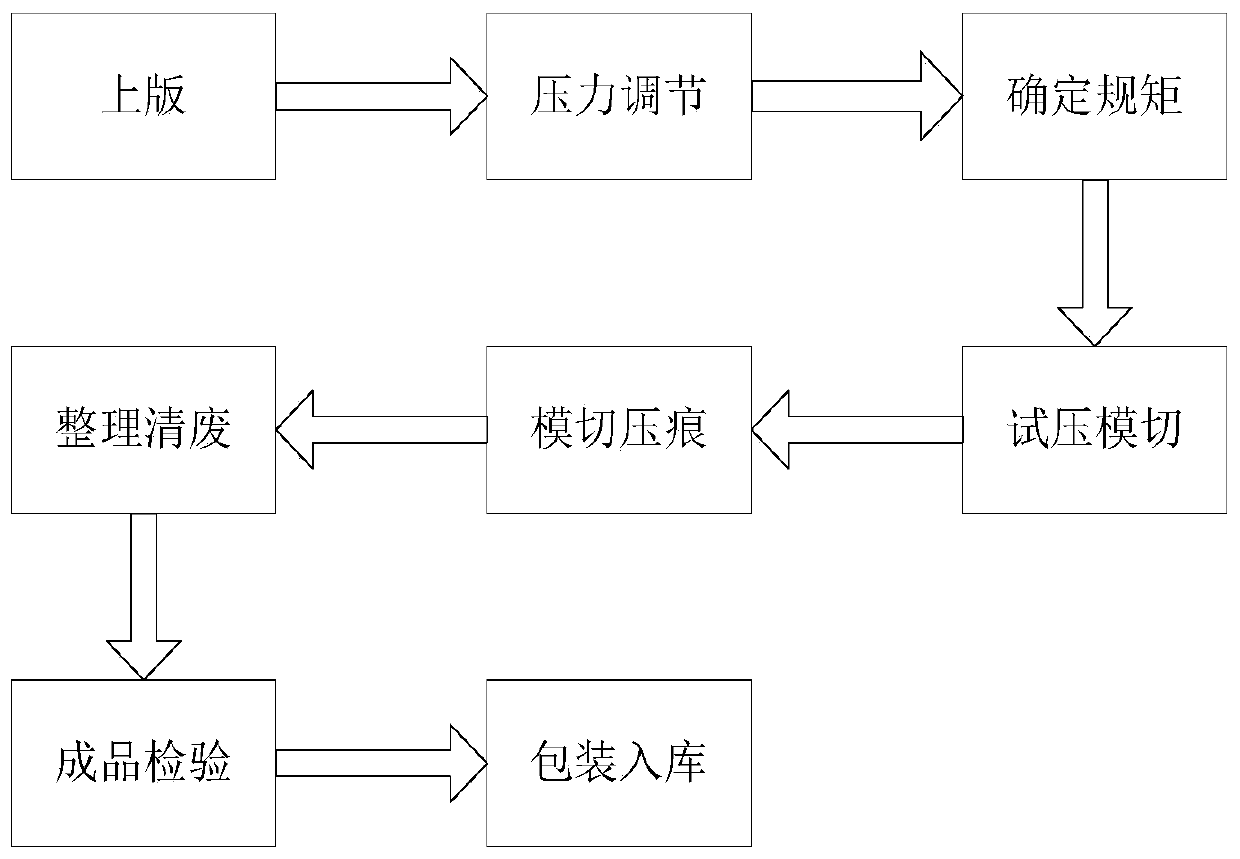

[0037] Such as Figure 1 to Figure 7 Shown, a kind of packaging carton die-cutting process comprises the following steps:

[0038] S1, upper version: install and fix the finished die-cutting plate 23 in the version frame of the die-cutting machine, and initially adjust the position;

[0039] S2. Pressure adjustment: Start the die-cutting machine to do 5-7 embossments, then use the carton board for pressure test, and adjust the die-cutting pressure evenly according to the knife marks on the carton board;

[0040] S3. Determine the rules: according to the position of the knife mark on the carton board in step S2, adjust the position of the carton board to the center position capable of containing the die-cutting board 23;

[0041] S4, pressure test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com