Die cutting mechanism with pole piece corner cutting, system comprising die cutting mechanism and method

A cutting mechanism and pole piece technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor battery consistency, battery self-discharge, battery temperature rise, etc., and achieve long mold life, reduced processing difficulty, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

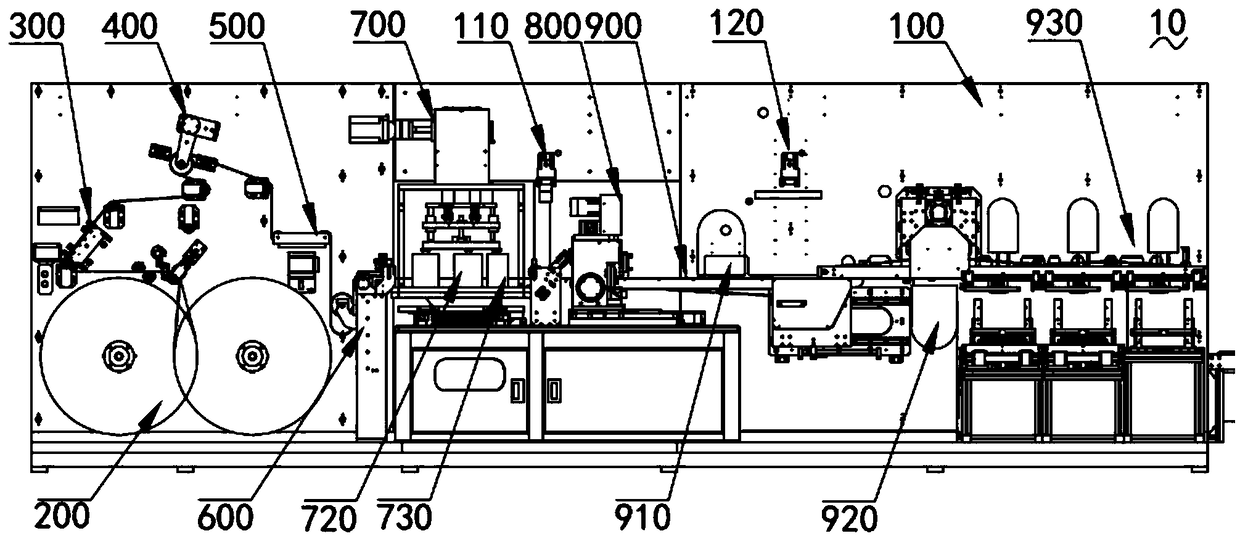

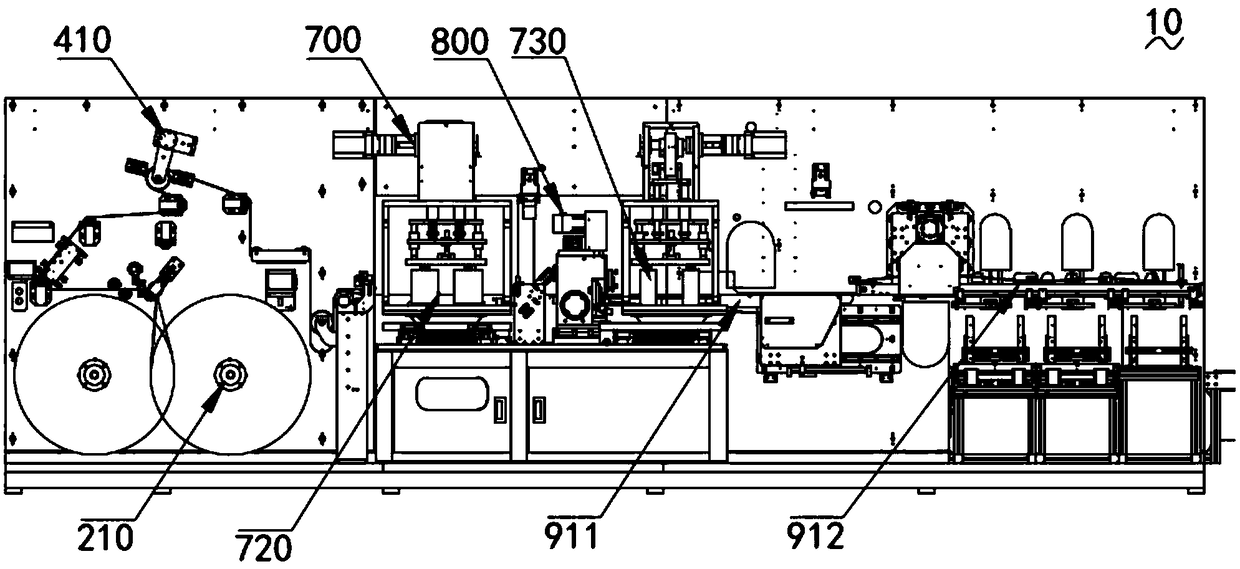

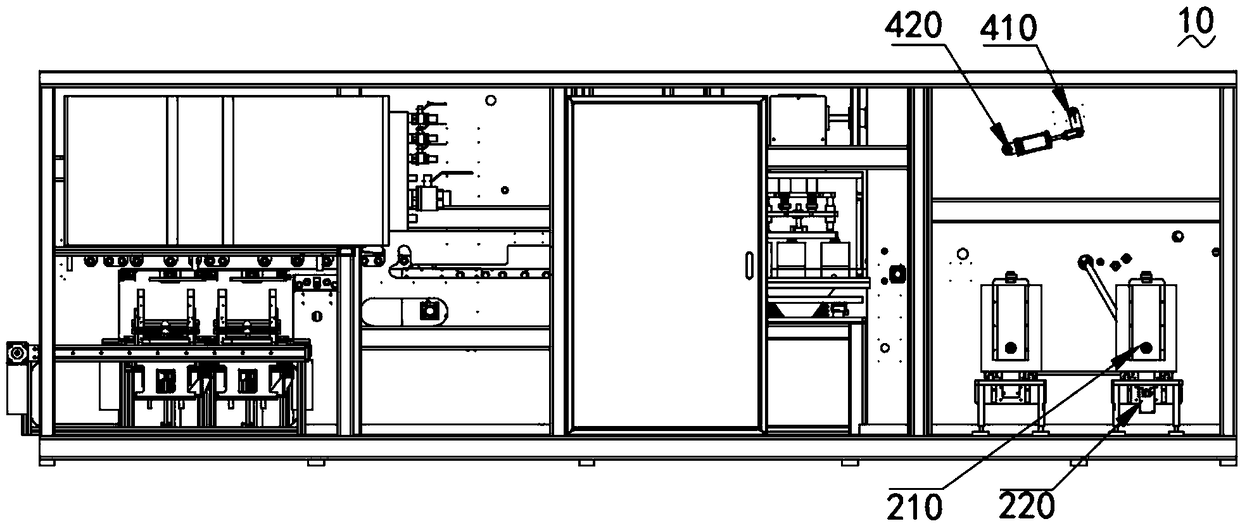

[0038] Such as Figure 1 ~ Figure 3 As shown, a die-cutting system 10 is provided with a frame 100, an uncoiling mechanism 200 for unwinding on the frame 100, a material receiving mechanism 300 for receiving unwinding mechanism 200, and a material receiving mechanism 300 for stretching the pole piece. The unwinding tension mechanism 400, the correction mechanism 500 for correcting and unwinding the pole piece, and the front storage mechanism 600 for storing the pole piece, the die-cutting mechanism 700 is installed on the frame 100 close to the front storage mechanism 600 On one side, the cutting mechanism 800 is located on the side of the die-cutting mechanism 700 away from the front sheet storage mechanism 600, the conveying mechanism 900 is located on the side of the cutting mechanism 800, and is installed on the frame 100 above the first powder brushing mechanism a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com