Foam double-sided tape and preparation method and application thereof

A technology of double-sided tape and foam, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of dust-free production environment pollution, residual glue pollution on the surface, and damage to parts, etc., to achieve Excellent resistance to shear force, good anti-warping resistance on curved surfaces, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

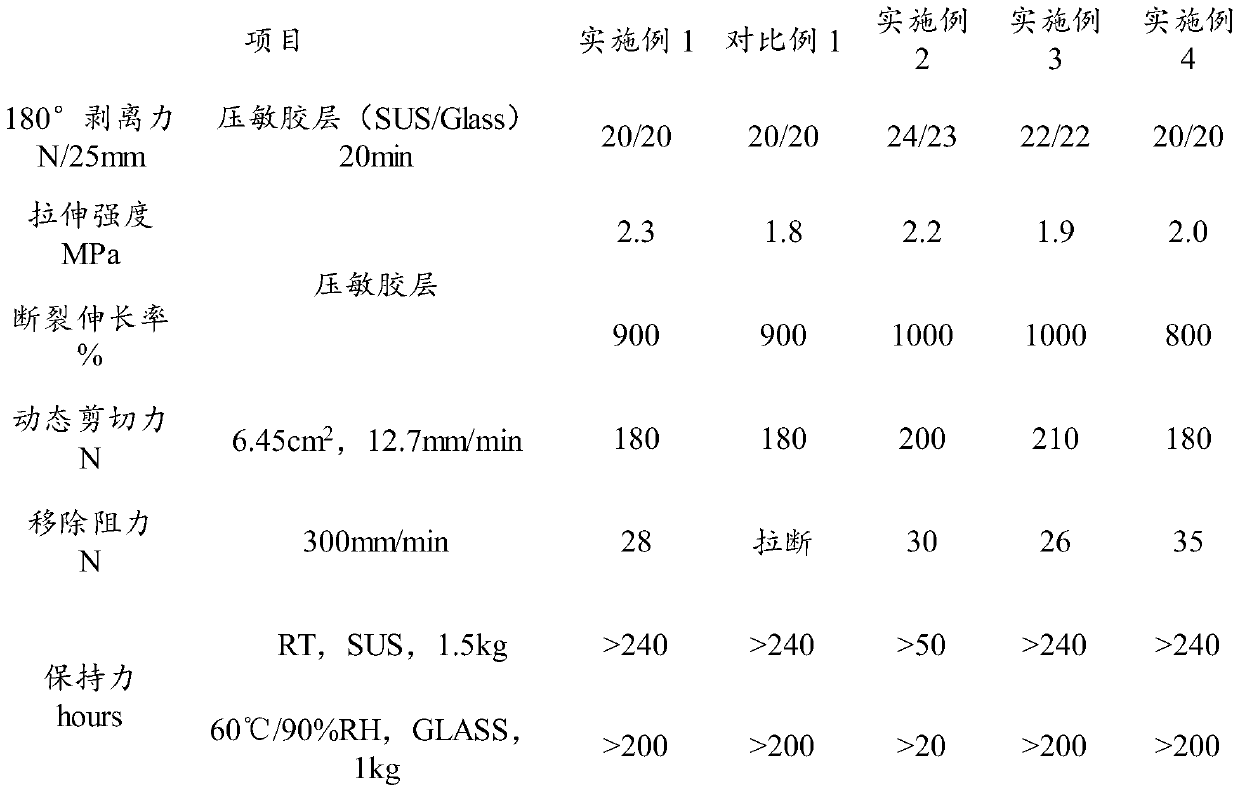

Examples

preparation example Construction

[0073] The present invention also provides a method for preparing the foam double-sided adhesive tape described in the above technical solution, comprising the following steps:

[0074] A pressure-sensitive adhesive layer is pasted or coated on both sides of the base material to obtain a foam double-sided adhesive tape. In the present invention, the base material and the pressure-sensitive adhesive layer are the same as those described in the above technical solution, and will not be repeated here.

[0075] The present invention has no special restrictions on the lamination / coating process, and the technical scheme of lamination / coating well-known to those skilled in the art can be adopted; Sensitive adhesive layer, the present invention has no special limitation to this. In actual operation, the pressure-sensitive adhesive layer has a release film (paper); in the present invention, the release film (paper) on one of the pressure-sensitive adhesive layers is preferably peeled...

Embodiment 1

[0092] The foam double-sided adhesive tape provided in Example 1 is composed of a base material and pressure-sensitive adhesive layers respectively compounded on both sides of the base material; the thickness of the base material is 700 μm, and the thickness of the pressure-sensitive adhesive layer is 50 μm; The thickness of the foam double-sided tape is 800 μm.

[0093] The base material is PE-EVA blended black foam with composite glue on both sides to composite POE film; the thickness of the POE film is 30 μm; the tensile strength of the PE-EVA blended black foam is 2.1MPa , the elongation at break is 800%; the preparation method of the substrate is specifically:

[0094] Dilute the dry oil-based composite glue (Henkel LA3640 / LA6800) with a solvent to a suitable solid content and viscosity, and then coat the obtained composite glue solution on the POE film with a coating thickness of 10 μm. After drying, the film will be covered with One side of the composite glue is therma...

Embodiment 2

[0108] The foam double-sided adhesive tape provided in Example 2 is composed of a base material and pressure-sensitive adhesive layers respectively compounded on both sides of the base material; the thickness of the base material is 700 μm, and the thickness of the pressure-sensitive adhesive layer is 50 μm; The thickness of the foam double-sided tape is 800 μm.

[0109] The base material is PE-POE blended black foam with POE film on both sides; the thickness of the POE film is 30 μm; the tensile strength of the PE-POE blended black foam is 2MPa, and the elongation at break The ratio is 1000%; the POE film on both sides of the substrate is compounded with the PE-POE blended black foam by a co-extrusion method before the PE-POE blended black foam is foamed to obtain a double-sided Laminated foam substrate.

[0110] The pressure-sensitive adhesive layer is prepared from the following raw materials: 50 parts by weight of styrene-ethylene / propylene-styrene block copolymer (SEPS),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com