Polyethylene composite film as well as preparation method and application thereof

A polyethylene and composite film technology, which is applied in the field of polyethylene materials, can solve the problems that the stiffness and flatness of PE composite films cannot be met, and the stiffness of PE composite films has decreased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method for the polyethylene composite film described in the above technical solution, comprising the following steps:

[0050] After melting and plasticizing the raw materials of the surface layer, the middle layer and the inner layer, the three-layer blown film co-extrusion method is used to co-extrude the blown film to obtain the primary composite film;

[0051] The primary composite film is sequentially subjected to longitudinal stretching and corona treatment to obtain a polyethylene composite film.

[0052] In the present invention, each component in the preparation method is consistent with the components of the polyethylene composite film in the above technical solution, and will not be repeated here.

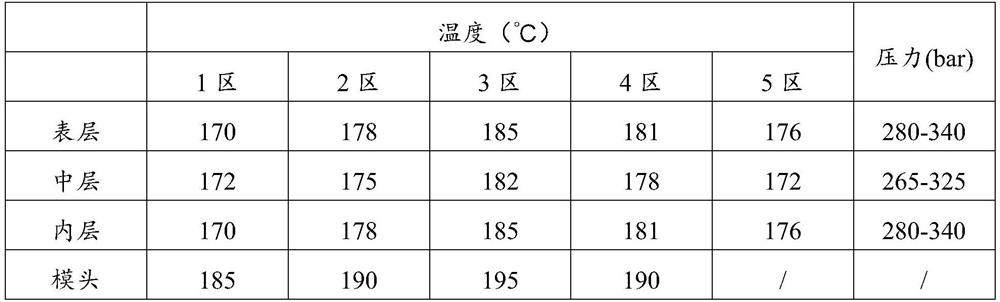

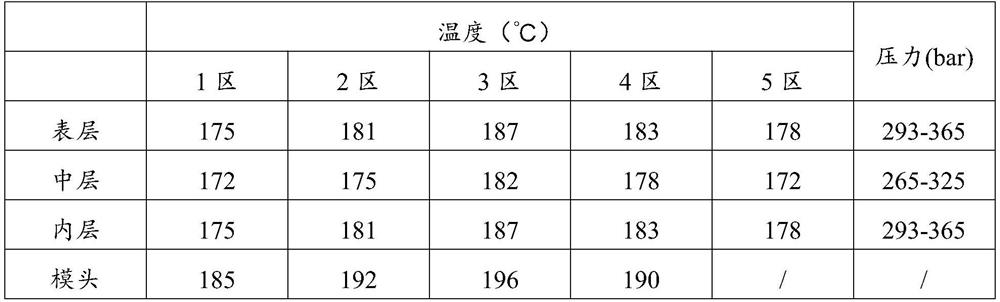

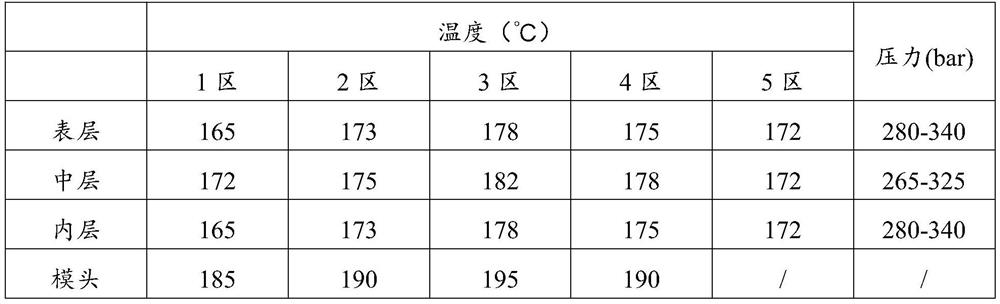

[0053] In the invention, the raw materials of the surface layer, the middle layer and the inner layer are melted and plasticized, and the three-layer blown film co-extrusion method is used to co-extrude the blown f...

Embodiment 1

[0069] In the polyethylene composite film prepared in this example, the mass ratio of the surface layer, the middle layer and the inner layer is 3:4:3; in terms of mass percentage, the surface layer includes 79% low-density polyethylene 2420H, 20% high-density polyethylene HD3355 and 1% of PA0801LD; by mass percentage, the middle layer includes 35% of low-density polyethylene 2420H, 12% of metallocene linear low-density polyethylene, 52% of high-density polyethylene H555JA and 1% of PA0801LD; by mass In percentage terms, the inner layer includes 79% low density polyethylene 2420H, 20% high density polyethylene HD3355 and 1% PA0801LD.

[0070] The preparation method is:

[0071] The raw materials of the surface layer, the middle layer and the inner layer are respectively mixed in proportion through the automatic batching system, and then sent to the extruder of the surface layer, the middle layer and the inner layer respectively, and the raw materials of the surface layer, the ...

Embodiment 2

[0076] In the polyethylene composite film prepared in this example, the mass ratio of the surface layer, the middle layer and the inner layer is 1:2:1, and the rest of the technical means are the same as in Example 1 to obtain a polyethylene composite film with a thickness of 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com