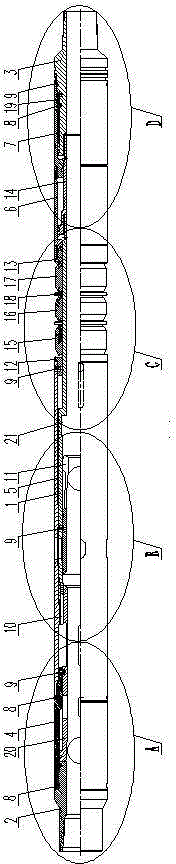

Hydraulic detachable packer with sliding sleeve

A packer, a desirable technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as early unsealing, low pressure bearing capacity, rubber tube and slips stuck, etc. Achieve the effect of convenient and reliable unpacking, safe and reliable recycling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

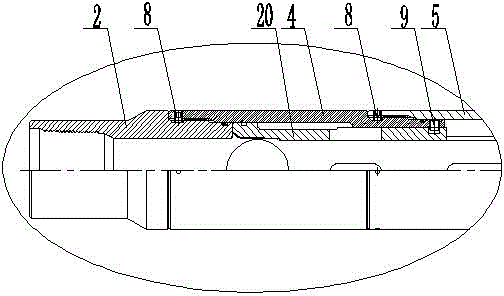

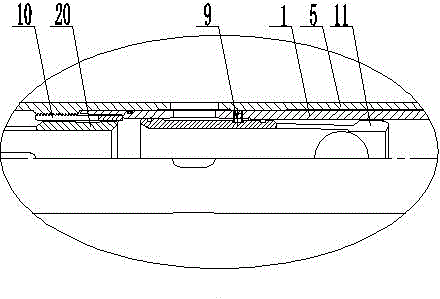

[0023] The hydraulic removable packer with a sliding sleeve includes a center pipe 1 , an upper joint 2 , a lower joint 3 , an intermediate joint 4 , a release jacket 5 , an upper piston 6 and a lower piston 7 . One end of the central pipe 1 is provided with a lower joint 3 through a connecting pipe 14, and the connecting pipe 14 is threadedly connected with the central pipe 1 and the lower joint 3 respectively.

[0024] The other end of the central tube 1 is equipped with an unblocking ball seat 20 through the release jacket 5, and the end of the unblocking ball seat 20 is equipped with the upper joint 2 through the intermediate joint 4, and the two ends of the intermediate joint 4 are connected to the upper joint through the set screw 8 respectively. 2 is connected with the release jacket 5; the intermediate joint 4 is connected with the unblocking ball seat 20 through the shear pin 9.

[0025] A release pawl 10 is provided between the release sleeve 5 and the unblocking bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com