Double-light-resistance wall and preparation method thereof

A technology of photoresist and photomask, applied in the field of double photoresist wall and its preparation, can solve problems such as insufficient bonding force of photoresist wall, Via hole seepage, glue overflow, etc., to reduce the risk of air bubbles and no glue, and increase the glued area , the effect of reducing the cavity volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

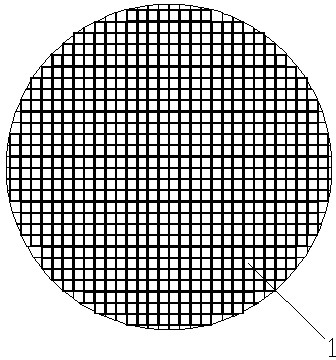

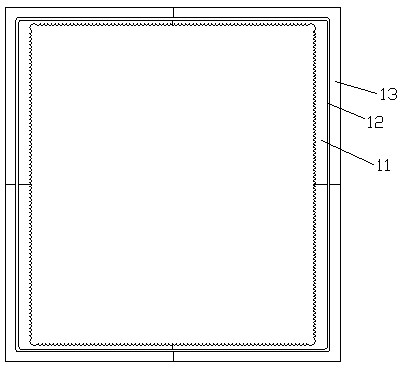

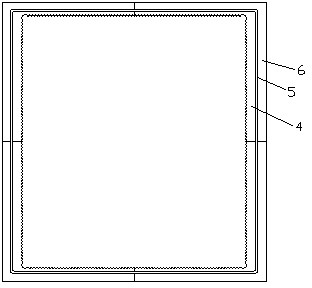

[0013] A method for preparing a double photoresist wall, which mainly includes the steps of cleaning glass, coating photoresist, exposing, developing and baking, and adopts a double photoresist wall mask in the exposure step, and the double photoresist wall mask is symmetrical It is provided with several double photoresist wall photomask units 1, and each double photoresist wall photomask unit comprises the photoresist wall 11 in the photomask unit, the photoresist wall 13 outside the photomask unit and the photomask unit cutting line 12, the photomask The photoresist wall outside the unit is arranged on the periphery of the photoresist wall inside the photomask unit, and the cutting line of the photomask unit is arranged between the photoresist wall inside the photomask unit and the photoresist wall outside the photomask unit; the exposure energy in the exposure step is 800-1000mJ / cm 2 ; The developing step adopts 10~11g / L of Na 2 CO 3 Solution, develop for 3 to 5 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com