Continuous fiber reinforced composite material additive manufacturing nozzle and printer

A reinforced composite material and continuous fiber technology, which is applied in the field of additive manufacturing, can solve the problems that the distance between the outlet of the inner head and the outlet of the outer head cannot be adjusted, the neutrality of the fiber composite material cannot be controlled, and the fiber filaments cannot be bonded together. Improvement of molding quality, easy cleaning of plugs, and reduction in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

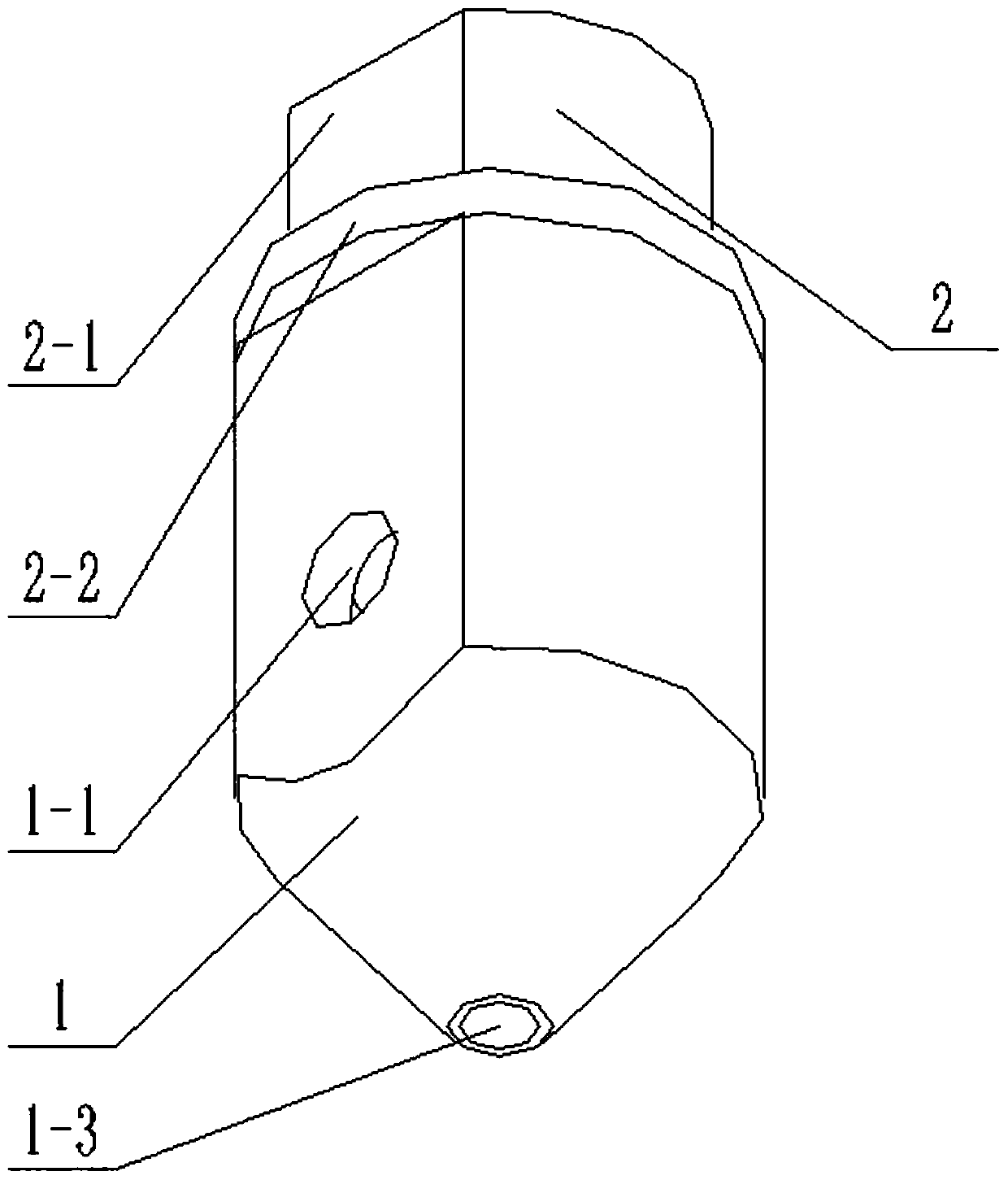

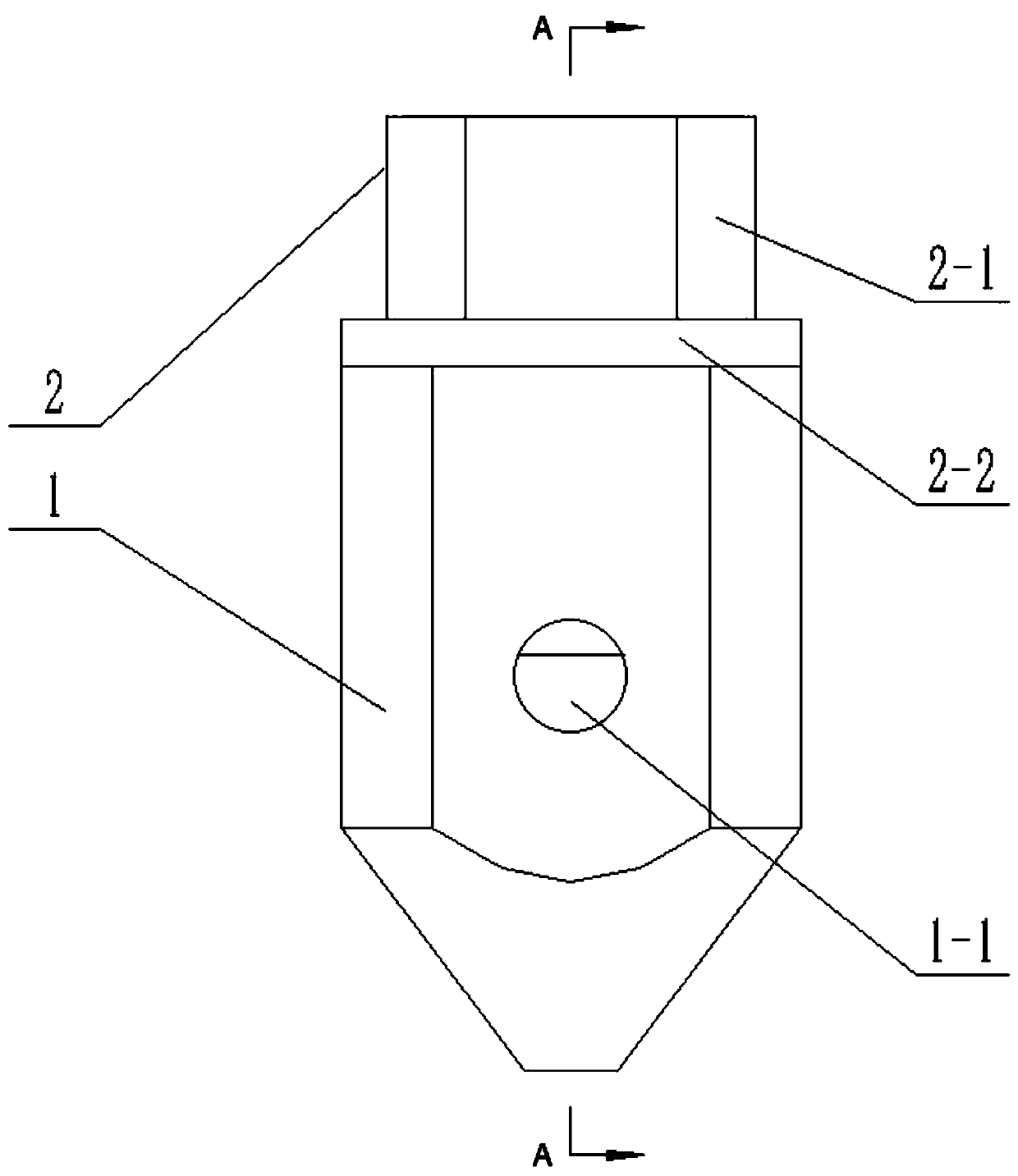

[0036] Combine below Figure 1-9 To explain this embodiment, the present invention belongs to the field of additive manufacturing. More specifically, it relates to a continuous fiber reinforced composite material additive manufacturing nozzle, which is composed of an outer nozzle 1 and an inner nozzle 2. The nozzle has a simple structure, a small size, and can be Improve the molding accuracy; in addition, the vertical distance between the outlet of the inner nozzle and the outlet of the outer nozzle is adjustable, which can control the centering of the fiber composite material and improve the molding quality.

[0037] The inner spray head 2 is threadedly connected to the inside of the outer spray head 1. The inner spray head 2 is provided with an inner cavity II2-3 for threading fibers, and the outer spray head 1 is provided with an inner cavity I1- containing resin material. 3. The inner cavity I1-3 is coaxial with the inner cavity II2-3, the outer nozzle 1 is also provided with...

specific Embodiment approach 2

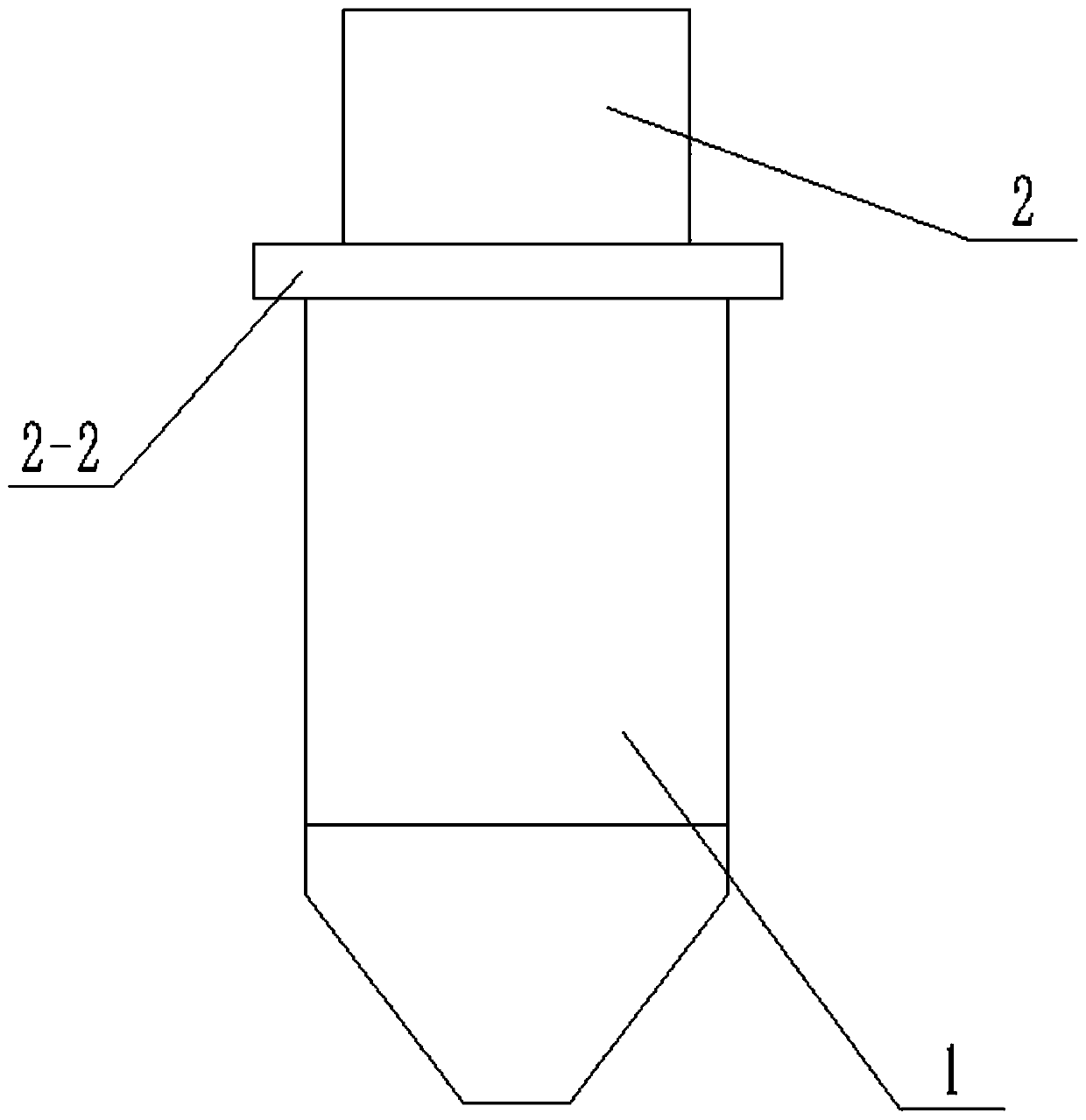

[0039] Combine below Figure 1-9 To illustrate this embodiment, this embodiment will further explain the first embodiment. The upper end of the outer nozzle 1 is a cylinder, and the lower end is a cone. Two planes are symmetrically provided on the cylinder, and the connecting hole 1-1 Located on one of the planes, a positioning hole 1-2 is provided on the other plane, and the positioning hole 1-2 is a threaded blind hole. The two symmetrical planes facilitate the fixing of the outer nozzle 1 and the heat conducting block, and also facilitate the processing of the connecting hole 1-1 and the positioning hole 1-2. The connecting hole 1-1 is a through hole provided with an internal thread for connecting a throat pipe. The positioning holes 1-2 are used to match the holes on the heat-conducting block, so that the heat-conducting block and the positioning holes 1-2 are fixedly connected by screws, so that the outer nozzle 1 and the heat-conducting block are fixedly connected togeth...

specific Embodiment approach 3

[0041] Combine below Figure 1-9 This embodiment will be described. This embodiment will further explain the first embodiment. The inner nozzle 2 is a cylinder, the upper end of the inner nozzle 2 has a larger diameter than the lower end, and the upper end of the inner nozzle 2 is provided with a tightening head 2-1. The lower end of the head 2-1 is provided with a stopper 2-2, the inner cavity II2-3 penetrates the inner nozzle 2 and is coaxial with the inner nozzle 2, and the inner cavity II2-3 is composed of two cylindrical cavities. The diameter of the cylindrical cavity is larger than the diameter of the lower cylindrical cavity, and the junction of the two cylindrical cavities is an arc transition. Tightening the head 2-1 facilitates the rotation of the inner spray head 2 with tools such as a wrench, and can make the inner spray head 2 and the outer spray head 1 tightly connected, thereby preventing the resin from overflowing from the gap between the inner spray head 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com