A shaft top layer arrangement structure of a machine room-less elevator

A machine room-less elevator and shaft technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of reducing the effective area of the elevator car, high installation requirements and difficulty, and increasing the top space of the machine room-less, etc. Achieve the effect of saving height and pit depth, maximizing effective area and improving product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following specific examples are only explanations of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

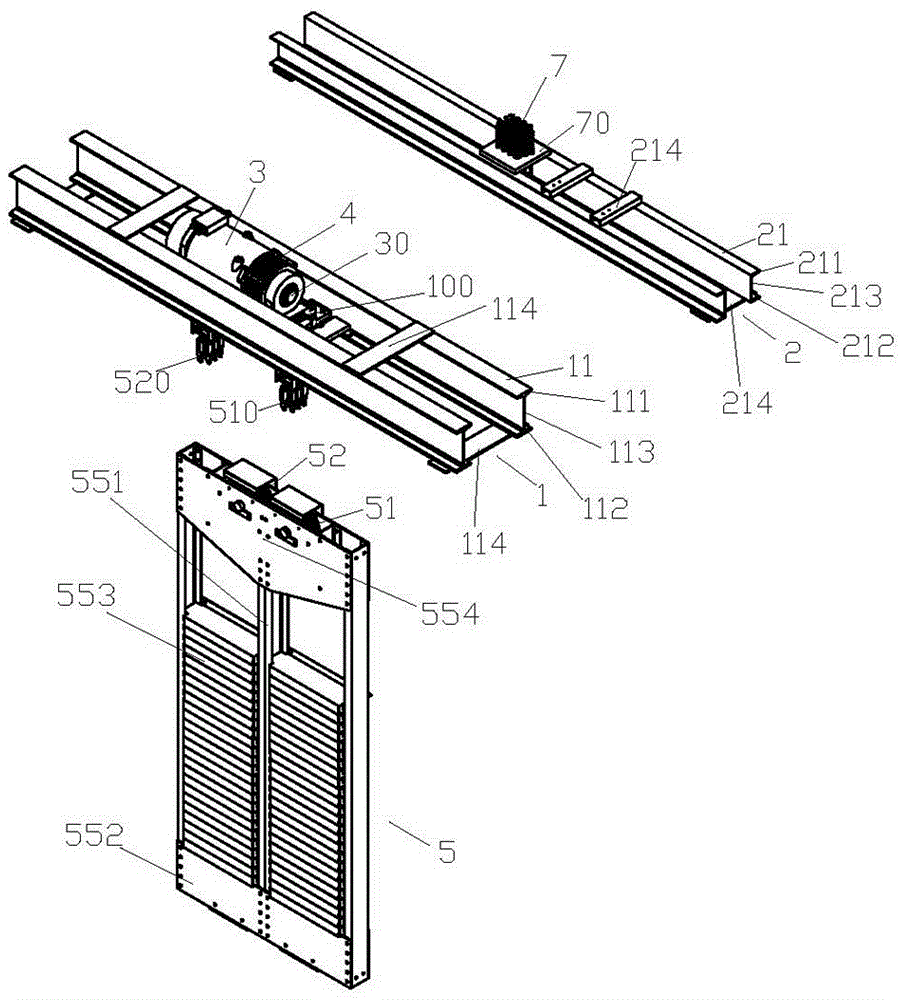

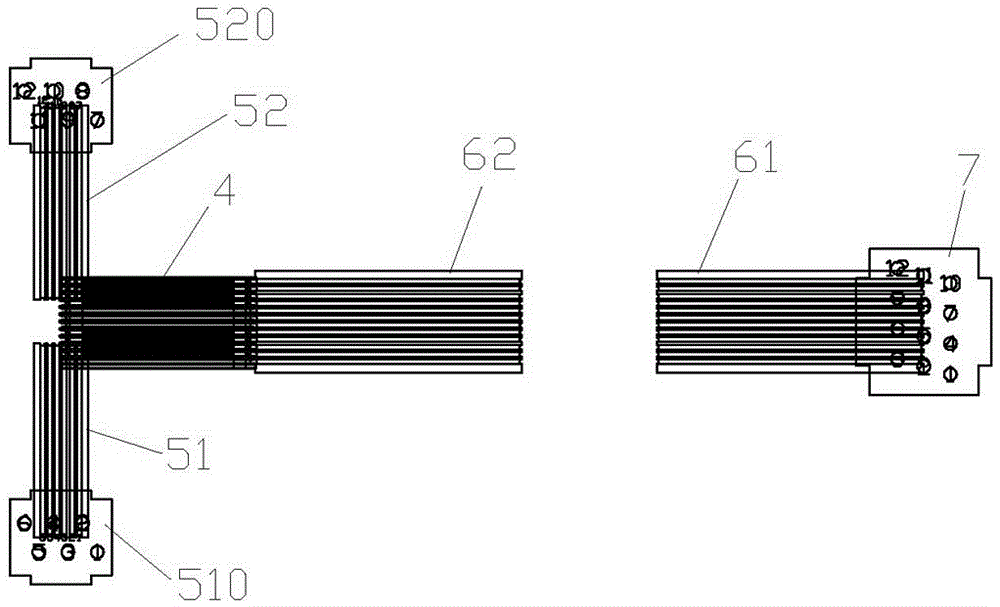

[0020] Examples such as figure 1 , 2 As shown in the figure, a shaft roof arrangement structure of a machine-room-less elevator includes a main beam frame 1 near the rear side wall of the shaft and a sub-frame frame 2 near the front side wall of the shaft arranged in parallel on the top layer of the shaft, and the main beam frame The two ends of 1 and the two ends of the auxiliary beam frame 2 are respectively fixed on the left side wall of the hoistway and the right side wall of the hoistway. The main beam frame 1 includes two main beams 11 arranged in parallel, and the two mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com