Glass substrate lithography alignment apparatus and aligning method characterized by no positioning marks

A glass substrate and photolithographic alignment technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of maximizing the effective use area, high-precision photolithographic alignment, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

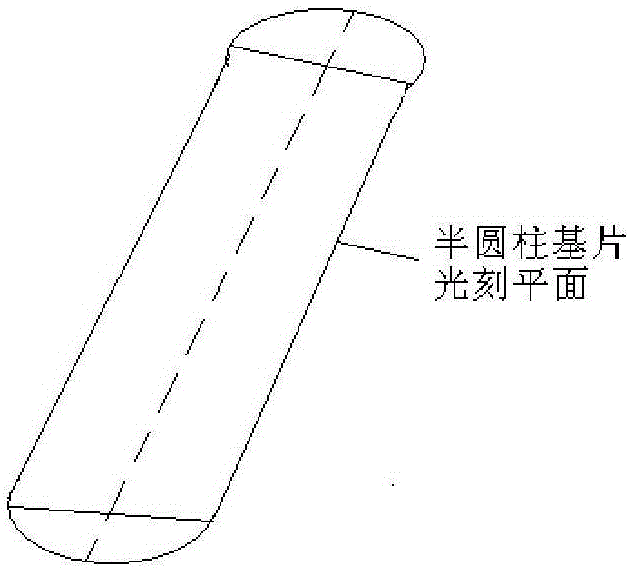

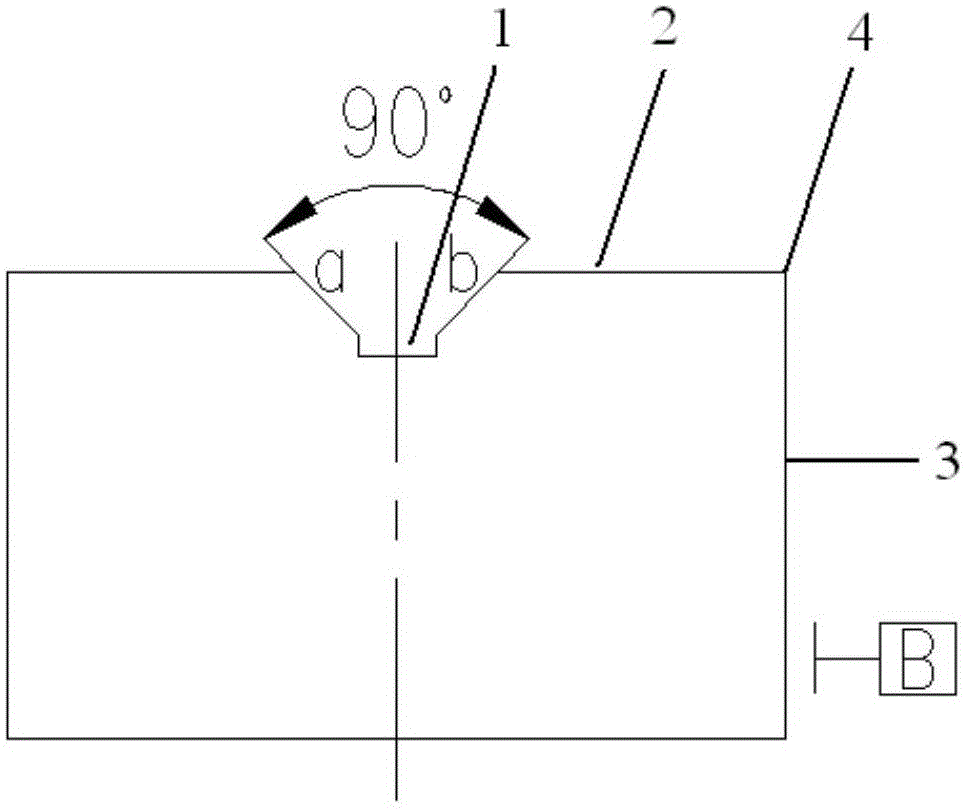

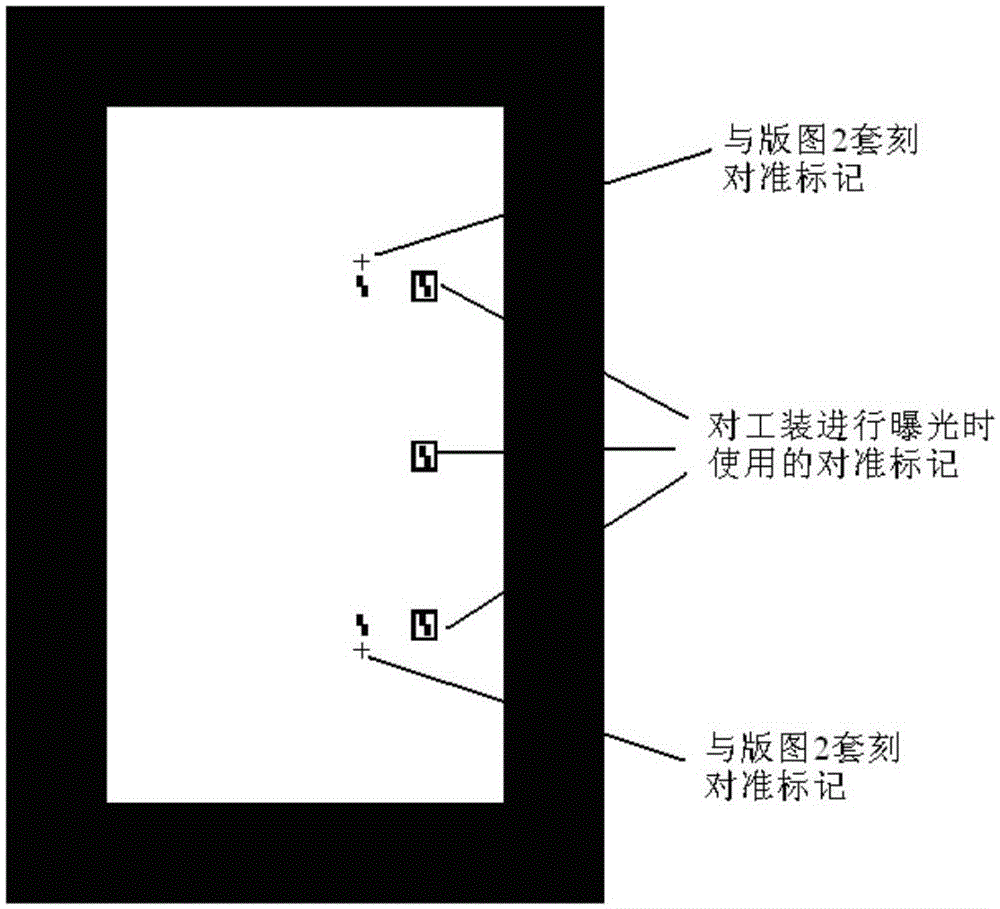

[0043] The present invention provides a set of photolithographic mask plates, which are used for photolithographic exposure of the positioning tool and the semi-cylindrical glass substrate. In the photolithography method provided in the implementation of the present invention, firstly, a high-precision positioning tool is designed and manufactured to firmly absorb the substrate when the semi-cylindrical glass substrate is photolithographically exposed. Measure the critical dimensions of the tooling and design a set (two pieces in total) of masks based on them. Use one of the mask plates to make a cross mark on the surface of the tooling by photolithography, and then use the cross mark to perform overlay alignment with the cross mark on the other mask plate, and finally realize the semi-automatic positioning without any positioning marks on the surface. The requirements for the photolithography alignment accuracy of the cylindrical glass substrate are specifically required to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com