A special-shaped beam-column steel frame with a sandwich panel and its construction method

A steel frame, special-shaped technology, applied in the direction of floor slab, building material processing, building components, etc., can solve the problems of increasing the cost, affecting the thermal insulation effect of beautiful walls, etc., to achieve strong fire prevention, thermal insulation and energy saving performance, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

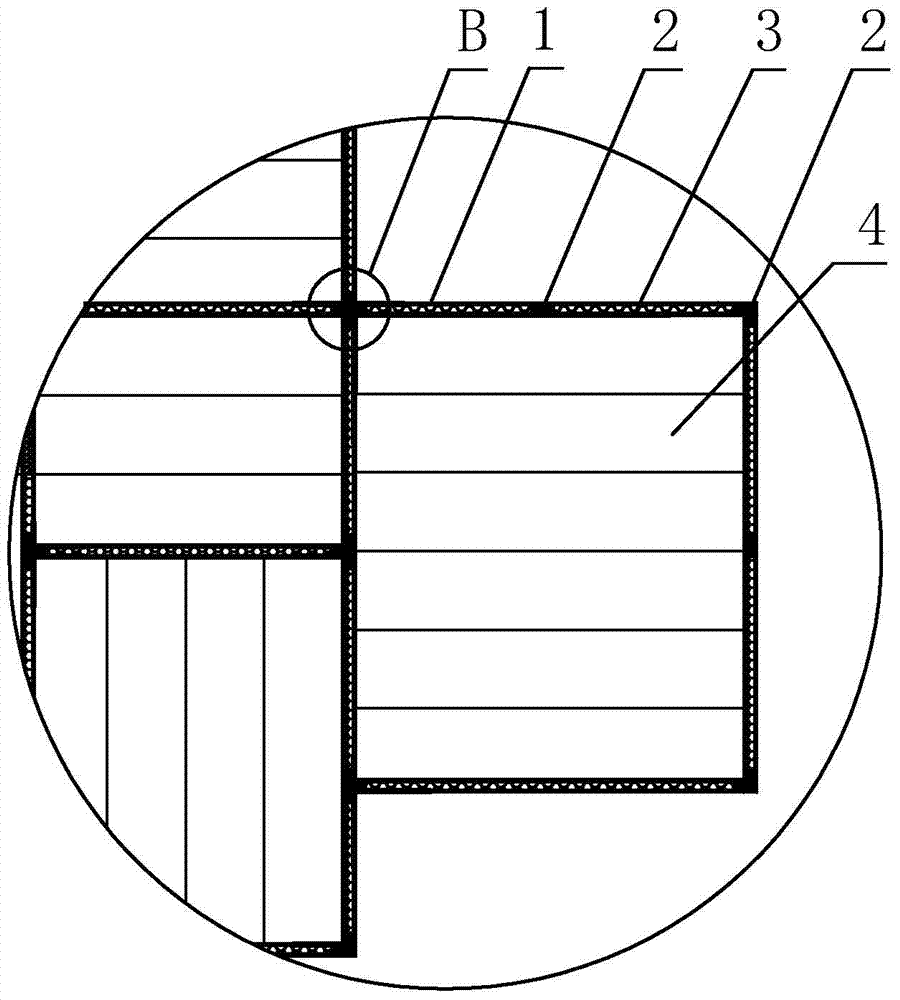

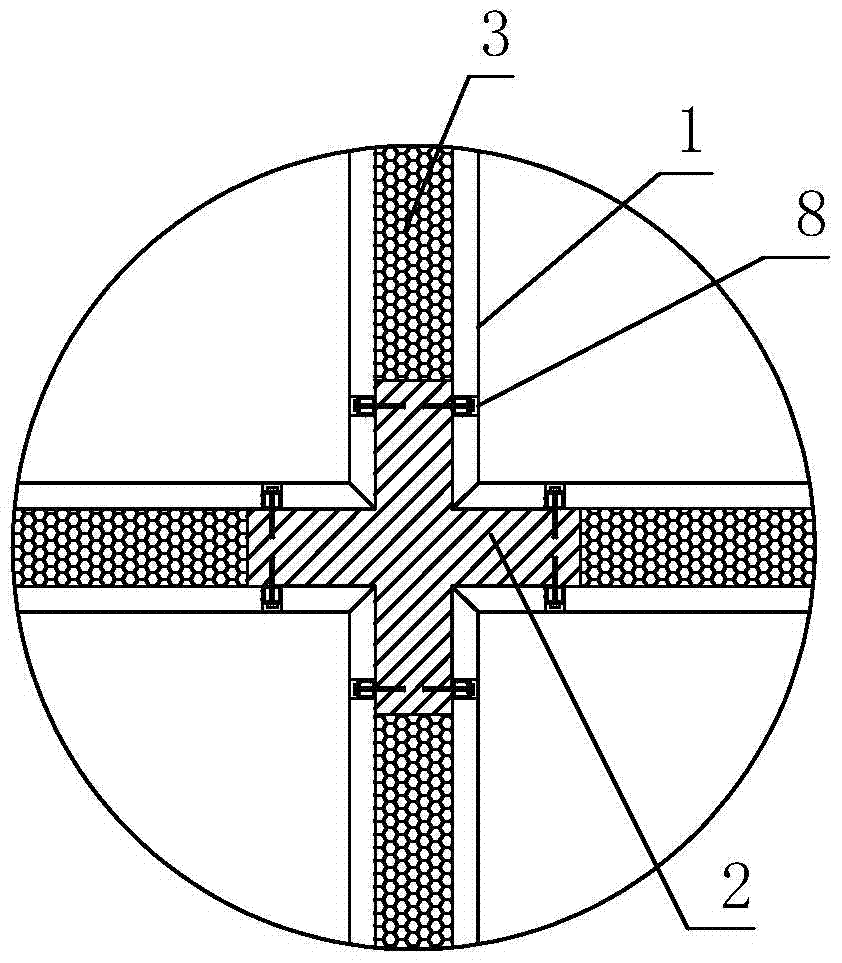

[0060] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , 2 The special-shaped beam-column steel frame with sandwich panels shown in , the steel frame is supported by special-shaped steel columns 2 and special-shaped steel beams 9, and each side of the special-shaped steel columns 2 and special-shaped steel beams 9 is covered by wall prefabricated panels 1 Cover tightly.

[0061] As for the special-shaped steel columns, together with the steel beams, they play a supporting role in the building as a whole.

[0062] like image 3 , 4 , 5, and 6, the cross-sectional shapes of the special-shaped steel column 2 are L-shaped, T-shaped, cross-shaped, and straight; no matter which shape of the special-shaped steel column, its side is covered by the wall prefabricated plate 1 and fixed. From the structure described later, it can be seen that the special-shaped steel beams are also covered by prefabricated floor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com