Method for treating canned citrus petal pectin wastewater

A technology for pectin wastewater and wastewater, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Glue purity is not high, to achieve the effect of no secondary pollution, avoiding difficult sludge dehydration, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

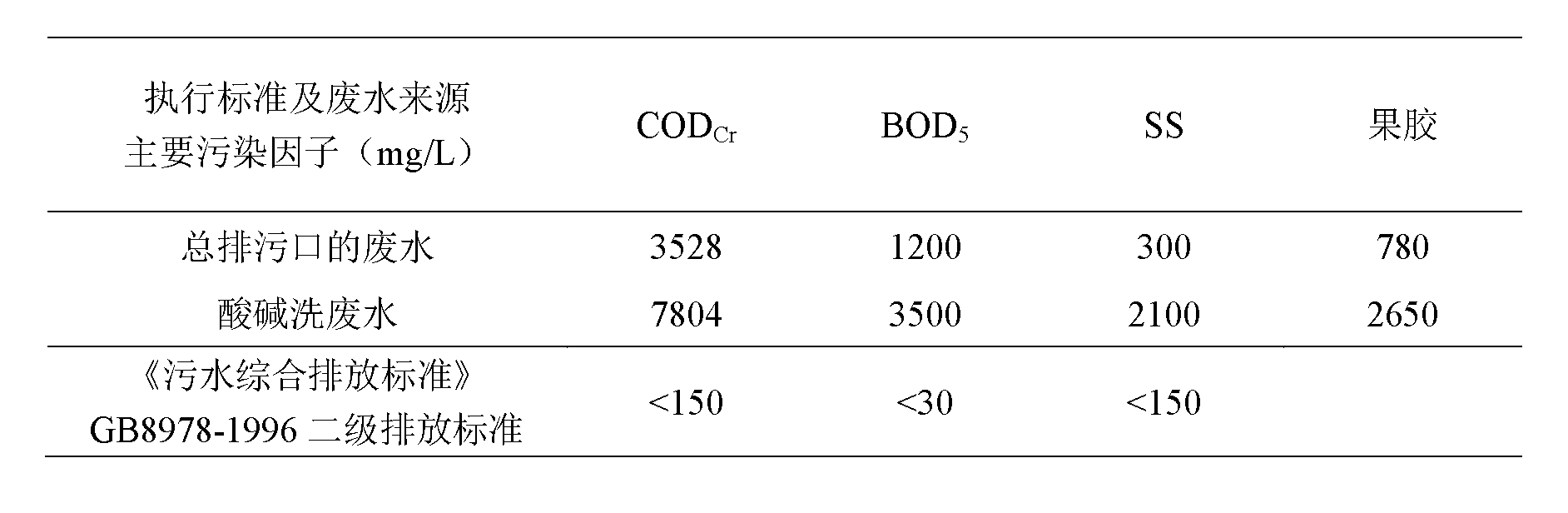

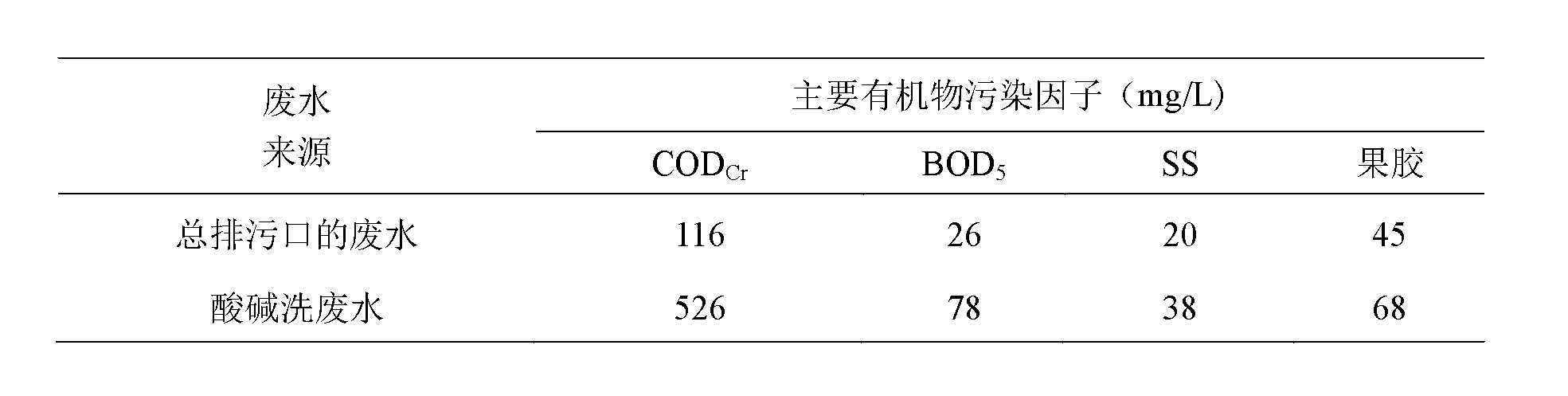

[0016] The following is illustrated by an implementation example: in the actual water sample of a canned citrus production plant in Hunan, the canned citrus pectin wastewater is acidic, with a pH value of 3 to 7, and the chemical oxygen demand (COD) of the second pollutant in the wastewater Cr ), five-day biochemical oxygen demand (BOD 5 ), the suspended solids (SS) content is high, far higher than the maximum allowable discharge concentration of the second type of pollutants in the "Comprehensive Wastewater Discharge Standard", and the pectin content in the wastewater is very high. 》Specific indicators of GB8978-1996 secondary emission standard are shown in Table 1.

[0017] Table 1 Water quality and discharge standard of canned citrus pectin wastewater

[0018]

[0019] Below in conjunction with accompanying drawing, the present invention is described further:

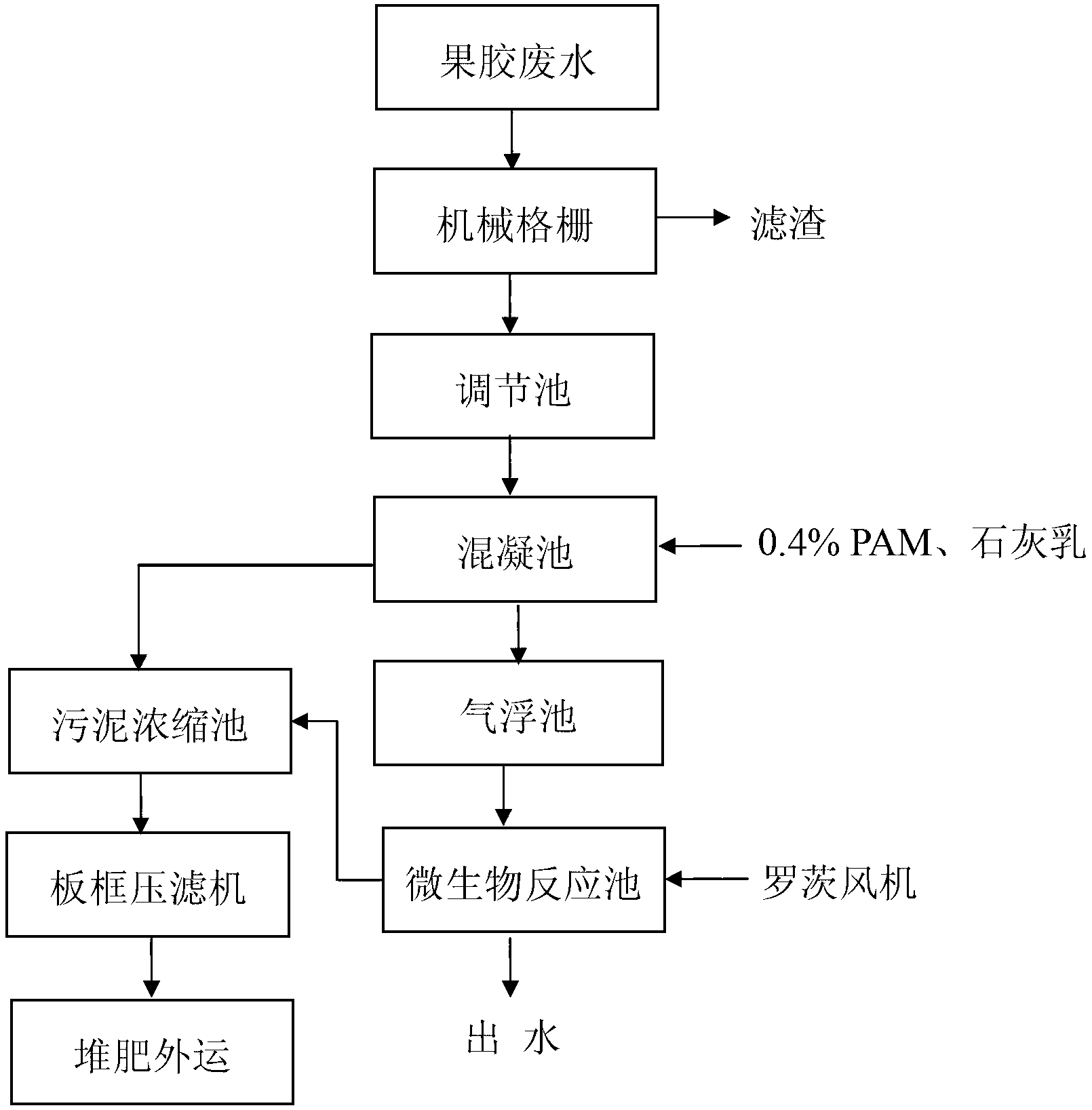

[0020] According to the operation process of the present invention, as the citrus canned pectin wastewater tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com