Method and device for treatment of high-temperature printing and dyeing wastewater

A treatment device and printing and dyeing wastewater technology, which is applied in the field of printing and dyeing industry, can solve the problems of printing and dyeing wastewater pollution and difficult treatment, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

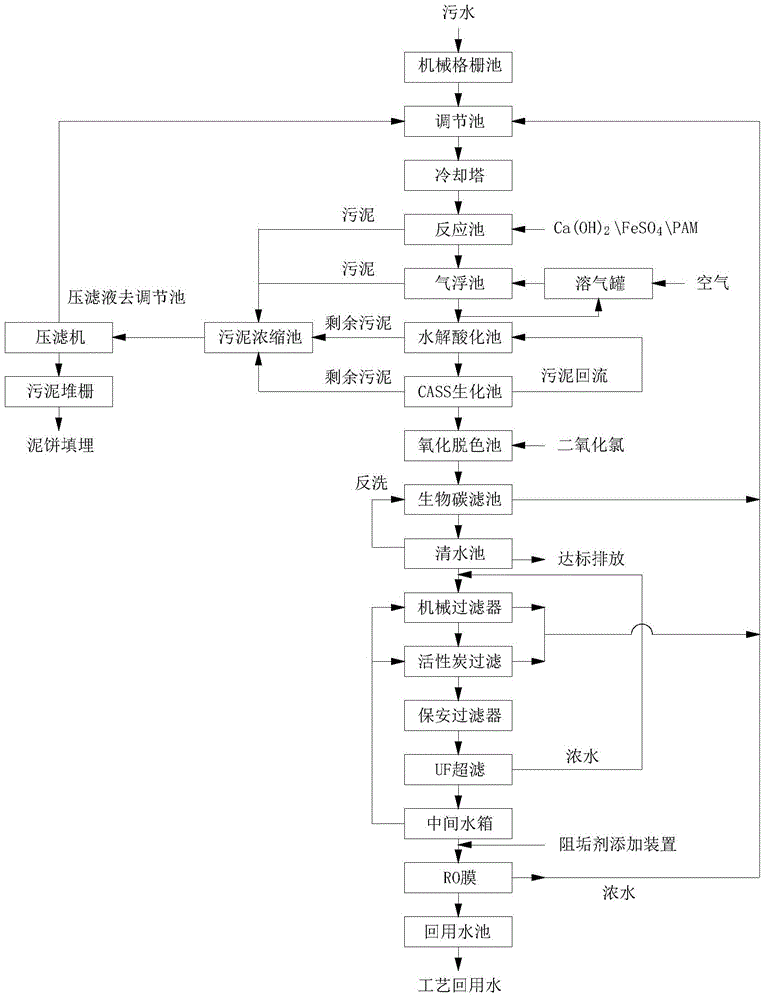

[0035] A treatment device for high-temperature printing and dyeing wastewater, comprising sequentially connected mechanical grid pools, regulating pools, cooling towers, reaction pools, air flotation pools, hydrolytic acidification pools, CASS biochemical pools, oxidation decolorization pools, biological carbon filters, clear water pools, Mechanical filter pool, activated carbon filter, security filter, UF ultrafiltration, intermediate water tank, RO membrane, reused water pool.

[0036] The reaction tank is connected with a coagulant feed pipeline, and the coagulant is Ca(OH)?\FeSO 4 \PAM.

[0037] The air flotation tank is connected with a pipeline to the dissolving tank, the dissolving tank is connected with an air pipeline, and the outlet pipe of the air flotation tank is connected with a return pipe to the dissolving tank.

[0038] The CASS biochemical tank is connected with a return pipe to the hydrolysis acidification tank; the sludge in the reaction tank and the air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com