Underground pipeline excavation-restoration construction method of stage temperature-control field pipe-making

A technology for underground pipelines and construction methods, which is used in pipeline laying and maintenance, pipes/pipe joints/pipes, mechanical equipment, etc., and can solve problems such as material bubbles, affecting the strength of new lined pipes, and resin boiling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

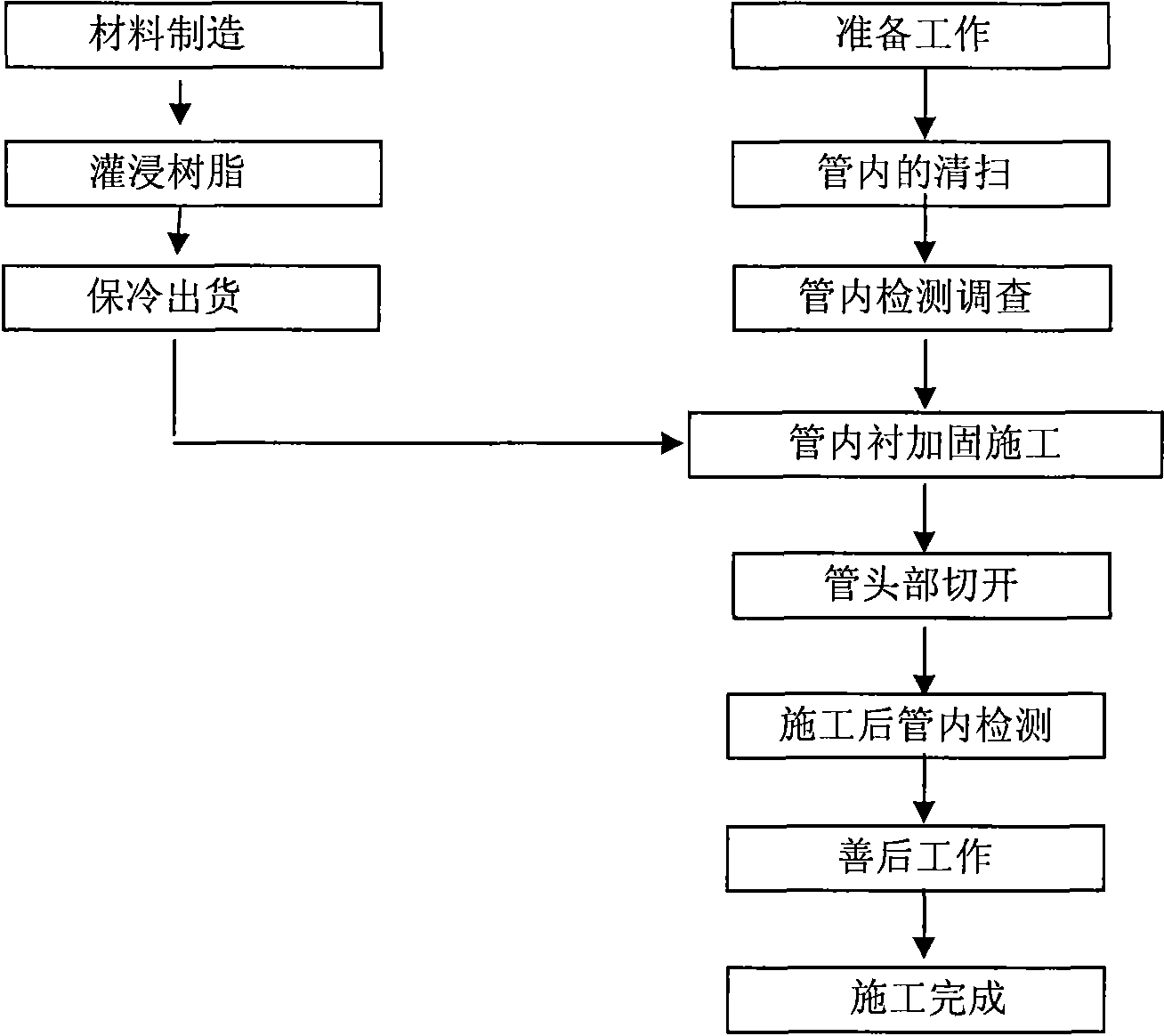

[0033] Underground pipeline repair of industrial sewage pipes in a certain road section in Shanghai.

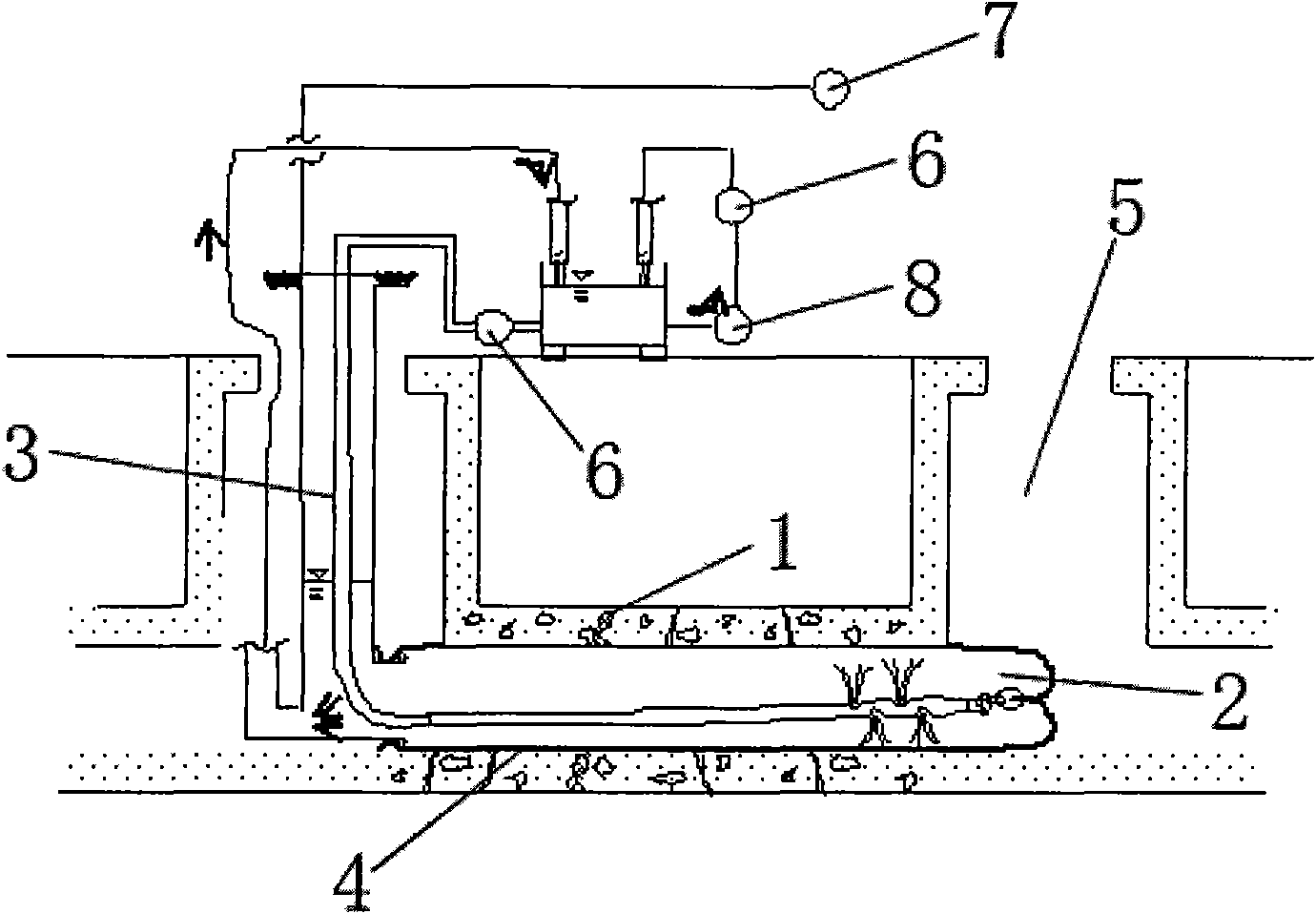

[0034] First of all, after the interpretation and evaluation of the image data of the underground pipeline through CCTV video inspection, it is found that the inside of the pipeline has been severely corroded, and the corrosion tendency of the pipeline is more serious, the load capacity of the pipeline itself is reduced, and the vibration of road vehicles will cause the pipeline to rupture. , collapsed, and then caused the subsidence and collapse of the pavement to be repaired in time.

[0035] Due to the heavy traffic on this section of the road, if large-scale excavation is used for repairs, the traffic will be seriously affected. Moreover, the construction period is long, the construction noise is large, and there is a lot of construction waste, which also has a great impact on the surrounding environment. In addition, large excavation is used for repair, and the construc...

Embodiment 2

[0051] In embodiment 1, add following operation:

[0052] After the cutting is carried out at the position where the nozzle of the lining material protrudes 5-6cm, a 45-degree chamfer is made between the lining material and the well wall with rapid cement. As a result, the nozzle part of the CIPP pipe after construction is kept smooth, and can be integrated with the well wall. This can achieve the purpose of anti-leakage and protection of the mouth of the nozzle.

Embodiment 3

[0054] In embodiment 2, add following operation:

[0055] While hardening the thermosetting resin hose, a layer of high-strength lining new pipe is formed in the old pipe, and at the same time, the CIPP lined pipe is expanded and tightly attached to the old pipe by using a water pressure 3.0m above the ground. the inner wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com