Recovering system for concrete cement mortar

A recycling system and cement slurry technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, etc. The problem of high energy consumption in production can reduce maintenance costs, reduce wear and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

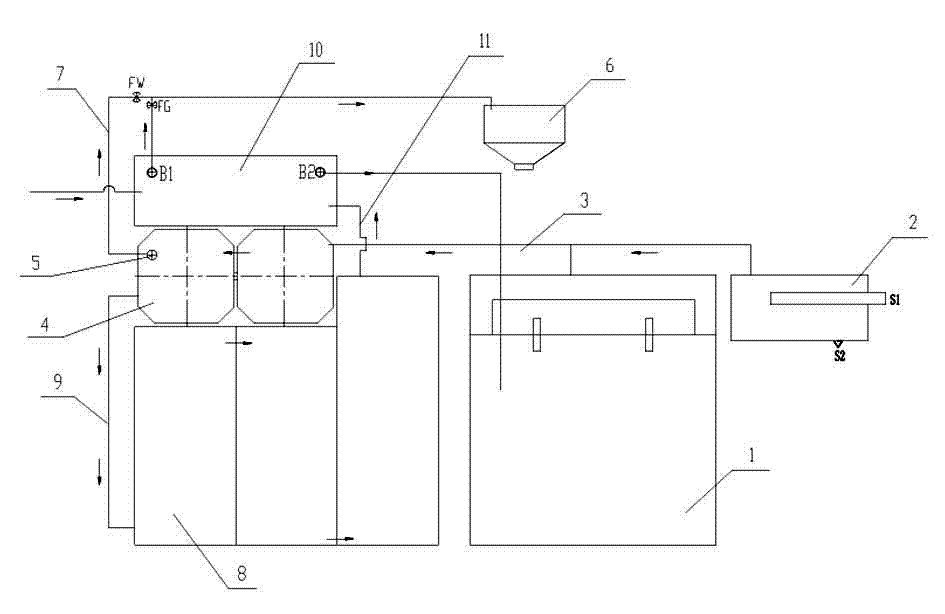

[0012] like figure 1 As shown, the concrete cement slurry recovery system of the present invention includes a car washing platform 1 and a sand and gravel separator 2 connected to the drainage tank of the car washing platform. The sand is discharged from the S1 port, and the stone is discharged from the S2 port; the stirring tank 4 is composed of two interconnected pools, and the outlet of the sewage pump 5 placed in the stirring tank 4 is connected to the sewage water supply extending to the top of the metering bucket 6. Pipeline 7; a sedimentation tank 8 is provided on one side of the stirring tank 4. The sedimentation tank 8 is composed of a first-level sedimentation tank, a second-level sedimentation tank and a third-level sedimentation tank that are connected to each other. The stirring tank 4 and the sedimentation tank 8 pass through the overflow pipeline. 9 is connected; a clear water tank 10 is arranged beside the stirring tank 4, and the water outlet pipe of the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com