Sewage heat exchange device for large-diameter shell-tube type fluidized bed

A technology of heat exchange device and large pipe diameter, which is applied in fluidized bed heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve problems such as dirt clogging, huge land occupation, and complicated process flow, and achieve Obvious environmental protection and economic benefits, high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

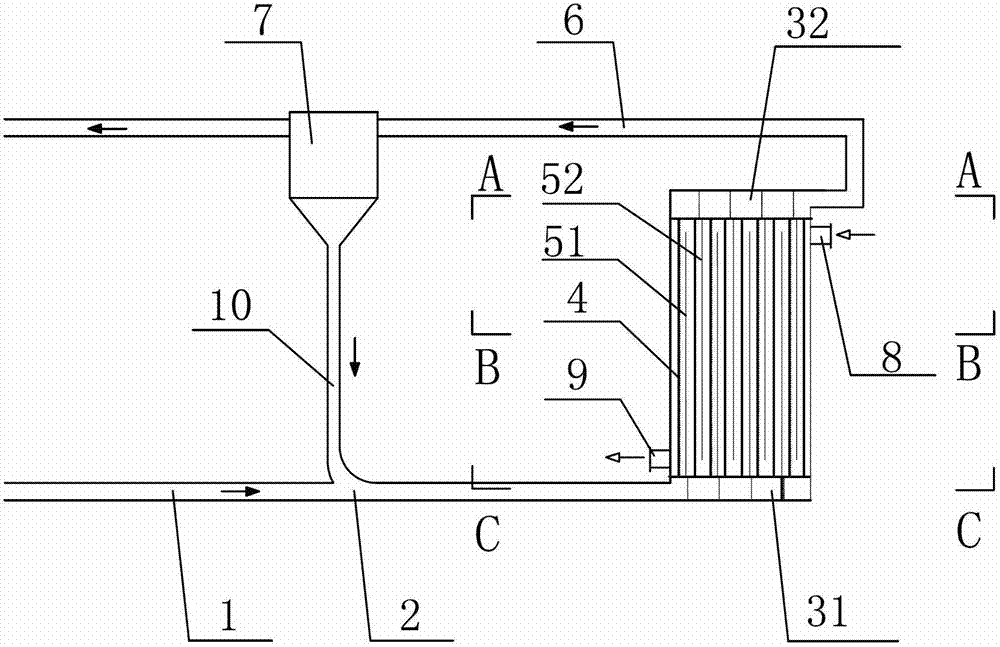

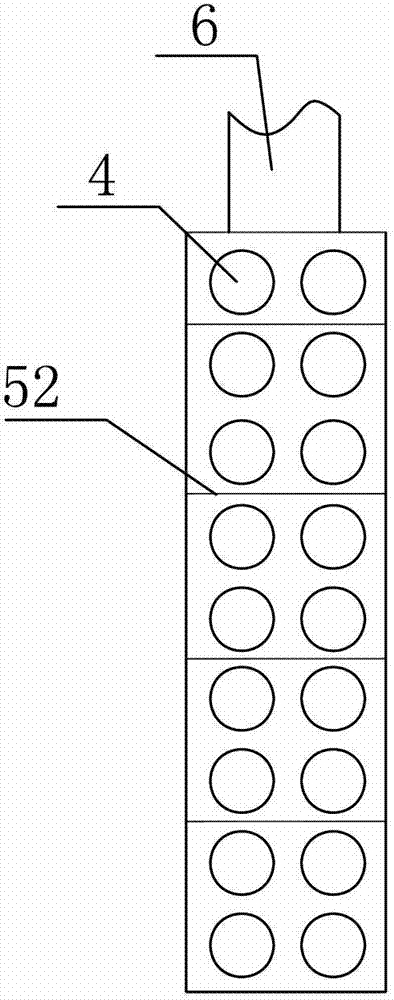

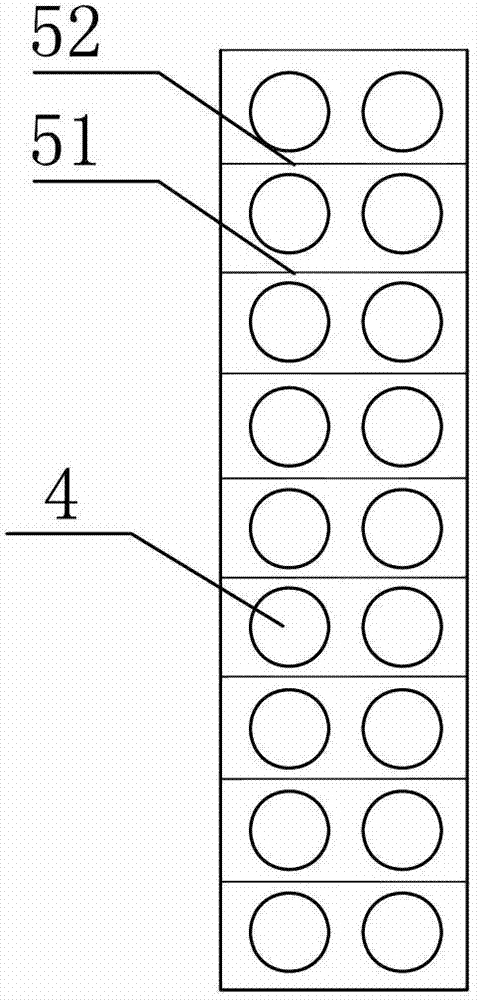

[0021] Such as Figure 1-5 As shown, the device of the present invention is composed of sewage or surface water inlet pipeline 1, downcomer bottom member 2, lower end sewage or surface water pipe box 31, large diameter pipe 4, upper end sewage or surface water pipe box 32, lower partition 51, The upper partition 52, the sewage or surface water outlet pipeline 6, the solid-liquid separator 7, the clean water inlet pipeline 8, the clean water outlet pipeline 9, the downcomer 10 and the like. Wherein, the pipe diameter of the large diameter pipe 4 is 50-120mm. Sewage or surface water is added to solid particles before entering the heat exchange device through the water inlet pipeline 1 to enhance the heat exchange capacity of the equipment and prevent dirt from clogging and the generation of dirt; sewage or surface water passes through the water inlet pipeline 1, the bottom member of the downcomer 2, Lower end sewage or surface water pipe box 31, large diameter pipe 4, upper end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com