Niobium-based Josephson junction etching method

A technology of junction etching and ion beam etching machine, which is applied in the manufacture/processing of superconductor devices, superconducting devices, electrical components, etc., and can solve problems such as differences in etching methods, impact on device performance, and multi-metal deposition. Achieve the effects of improving yield and productivity, reducing Nb layer damage, and simple etching method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

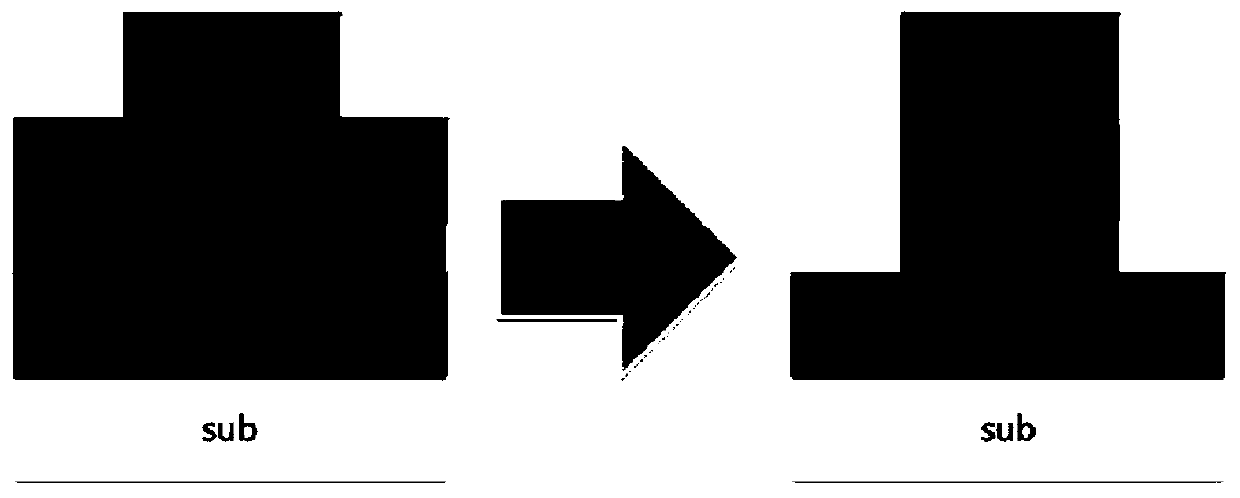

[0037] A niobium-based Josephson junction etching method, see image 3 , the niobium-based Josephson junction includes mask material (Mask), Nb layer, AlO x / Al layer, Nb layer and bottom layer material (sub), the mask material is photoresist, the bottom layer material is Si not as a functional layer, wherein the thickness of the upper Nb layer is 150nm, AlO x The thickness of AlOx in the / Al layer is 1nm, the thickness of the Al layer is 9nm, the thickness of the lower Nb layer is 150nm, and the shape of the device is a truncated cone. The etching gas is C4F8; the inert gas is Ar gas.

[0038] The niobium-based Josephson junction is under the condition of not interrupting the vacuum environment during processing, and the specific steps of the etching method are as follows:

[0039] Step 1. In a vacuum state, put the niobium-based Josephson junction sample to be etched into the transfer device, and the transfer device transfers the sample to the reactive ion etching chamber;...

Embodiment 2

[0045] A niobium-based Josephson junction etching method, the niobium-based Josephson junction sequentially includes mask material (Mask), Nb layer, AlO x / Al layer, Nb layer and bottom layer material (sub), the mask material is a hard mask, and the bottom layer material is SiO, which is not used as a functional layer. The thickness of the upper Nb layer is 150nm, AlO x The thickness of AlOx in the / Al layer is 1nm, the thickness of the Al layer is 9nm, the thickness of the lower Nb layer is 150nm, and the shape of the device is square platform. The etching gas is C4F8, and the etching gas is He.

[0046] The niobium-based Josephson junction is under the condition of not interrupting the vacuum environment during processing, and the specific steps of the etching method are as follows:

[0047] Step 1. In a vacuum state, put the niobium-based Josephson junction sample to be etched into the transfer device, and the transfer device transfers the sample to the reactive ion etchi...

Embodiment 3

[0053] A niobium-based Josephson junction etching method, the niobium-based Josephson junction sequentially includes mask material (Mask), Nb layer, AlO x / Al layer, Nb layer and bottom layer material (sub), the mask material is photoresist, and the bottom layer material is SiN, which is not used as a functional layer. The thickness of the upper Nb layer is 150nm, AlO x The thickness of AlOx in the / Al layer is 1nm, the thickness of the Al layer is 9nm, the thickness of the lower Nb layer is 150nm, and the shape of the device is long strip. The etching gas is C4F8, and the inert gas is Ne gas.

[0054] The niobium-based Josephson junction is under the condition of not interrupting the vacuum environment during processing, and the specific steps of the etching method are as follows:

[0055] Step 1. In a vacuum state, put the niobium-based Josephson junction sample to be etched into the transfer device, and the transfer device transfers the sample to the reactive ion etching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com