Horizontal four-axis blender

A mixer and horizontal technology, which is applied in the field of horizontal four-shaft mixers, can solve the problems of difficulty in flapping and tumbling, and it is difficult to meet the requirements of the mixing process, and achieves the effect of reducing possibility and high-efficiency mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

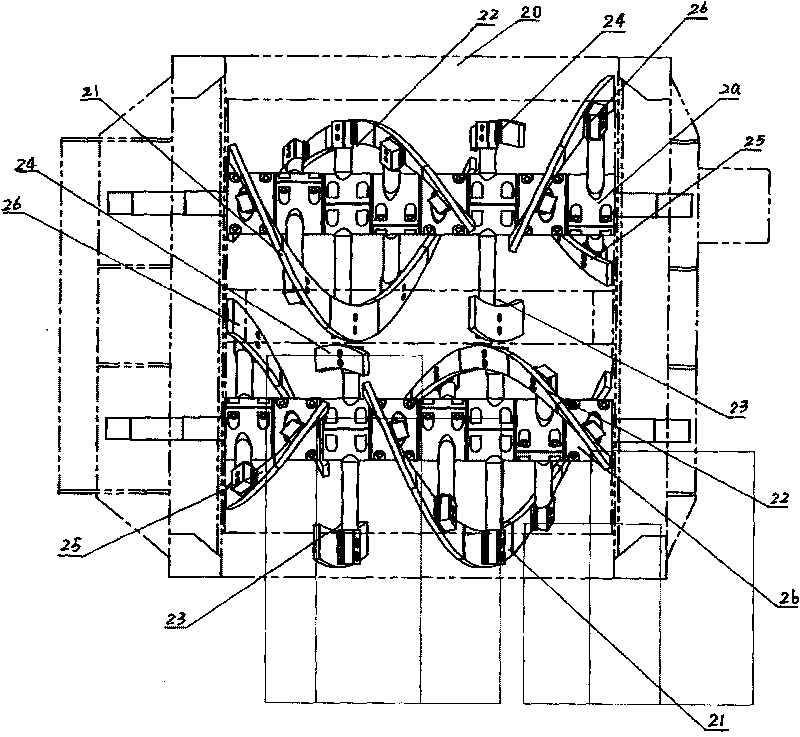

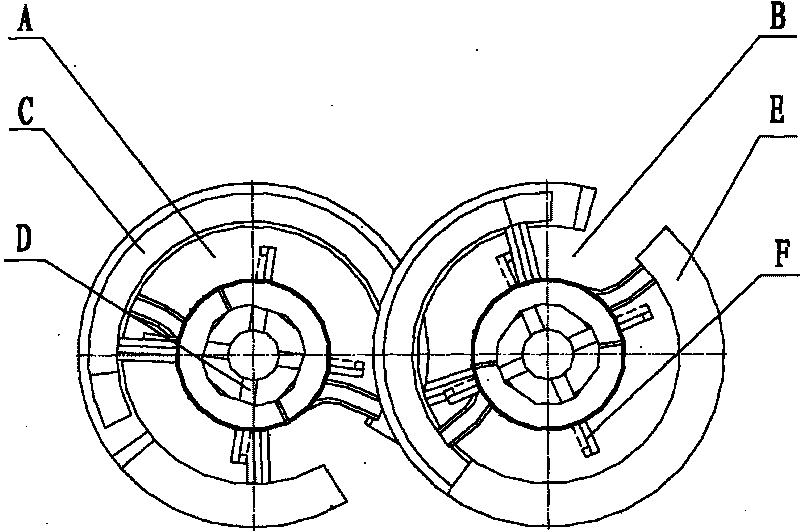

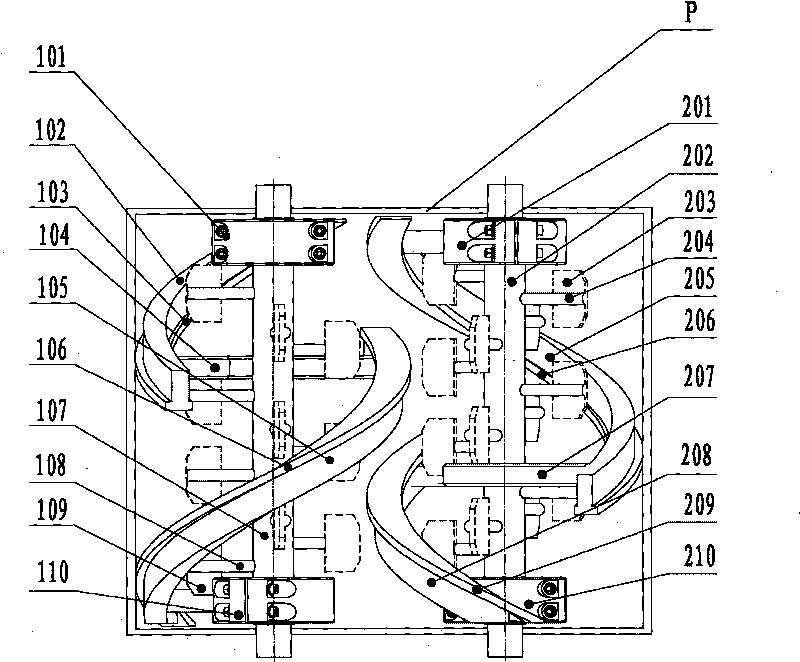

[0034] see figure 2 and image 3 , the horizontal four-axis mixer is equipped with a body P, a left mixing system A and a right mixing system B, and the left mixing system A has a left outer stirring mechanism C placed horizontally and a built-in left outer stirring mechanism C and connected with the left outer stirring mechanism C coaxial left inner stirring mechanism D; right stirring system B has a horizontally placed right outer stirring mechanism E and a right inner stirring mechanism built in the right outer stirring mechanism E and coaxial with the right outer stirring mechanism E F.

[0035] The left outer stirring mechanism C is equipped with a screw shaft feeding unit and the screw shaft returning unit, and the right outer stirring mechanism E is equipped with a screw shaft feeding unit and a screw shaft returning unit. The left outer stirring mechanism C and the right outer stirring mechanism E are arranged along the axial direction Arranged crosswise in opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com