Direct hydrocarbon fuel solid oxide fuel cell anti-carbon deposition anode and a preparation method thereof

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of bloated solid oxide fuel cell systems, blockage of anode pores, and anode structure damage, and achieve structural stability. , avoid peeling, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Direct use of hydrocarbon fuel cells Lanthanum-doped strontium titanate-cerium oxide anode resists carbon deposition anode material with composition xSr 0.55 La 0.3 TiO 3 -(1-x)CeO 2 (x=0.5).

[0026] Firstly, the lanthanum-doped strontium titanate material was prepared, and the La 2 o 3 , SrCO 3 、TiO 2 Weigh according to the stoichiometric ratio, add it to a ball mill tank, use alcohol as the ball mill medium, and ball mill it on a planetary ball mill at 400 rpm under controllable conditions for 3 hours to mix evenly, and then blow the mixed slurry at 70°C Dry in a type drying oven; put the dried powder into an alumina crucible and send it to a muffle furnace for calcination at 1250°C for 3 hours to obtain a doped strontium titanate material.

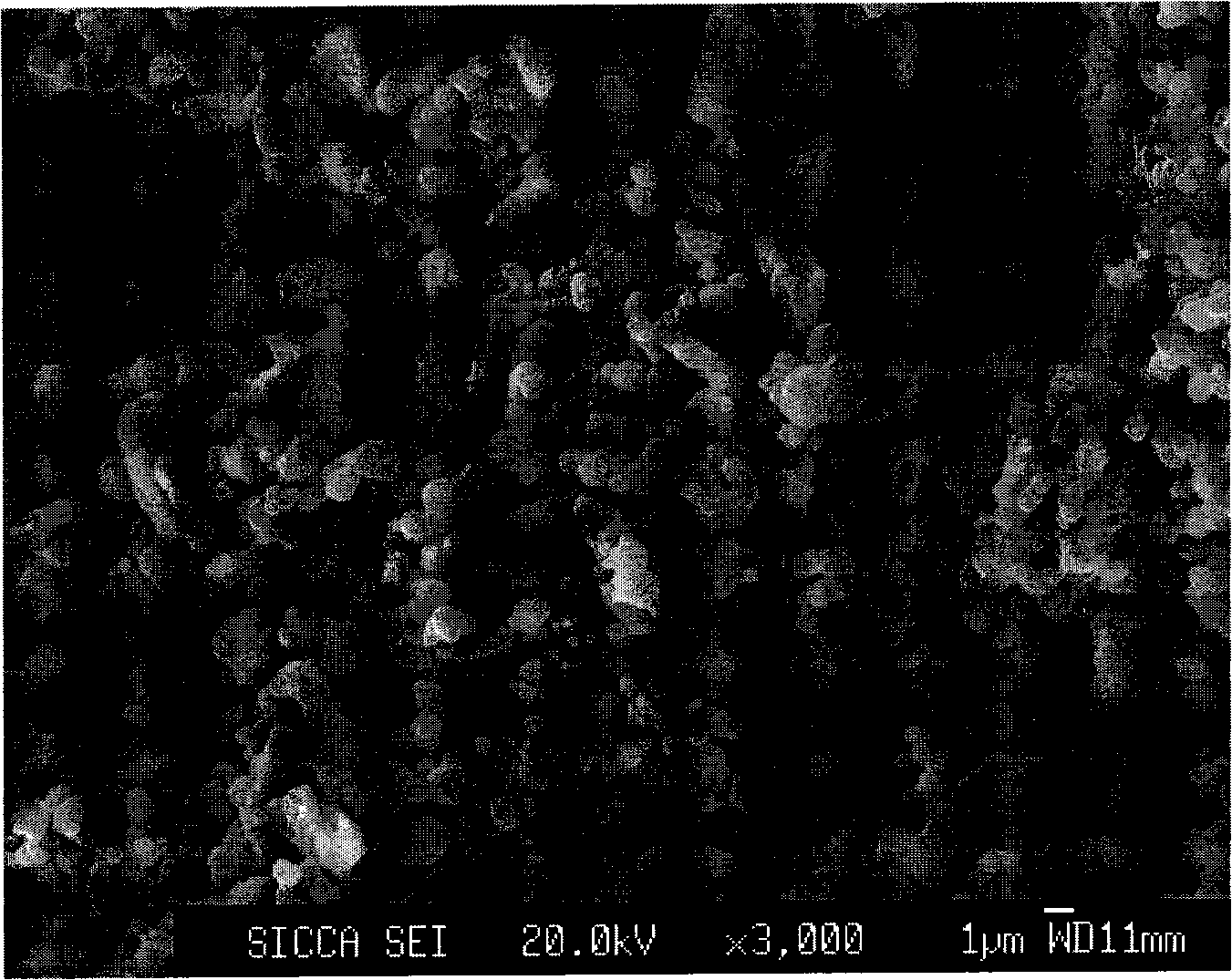

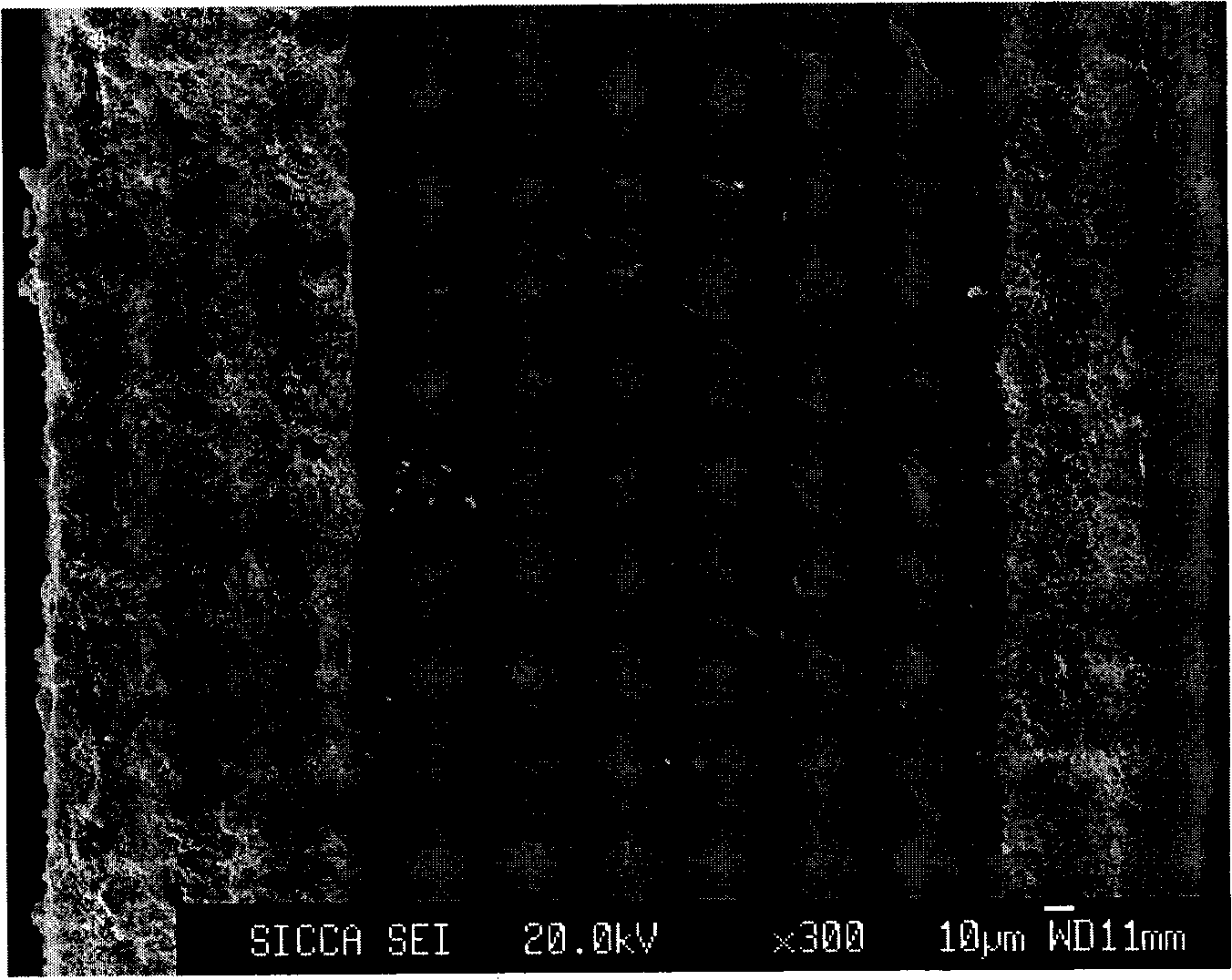

[0027] The prepared Sr 0.55 La 0.3 TiO 3 Powder and CeO 2 The powder is put into the ball mill tank according to the weight ratio of 1:1, and the alcohol is used as the ball milling medium, and the ball milling is car...

Embodiment 2

[0031] Direct use of hydrocarbon fuel cells yttrium-doped strontium titanate-cerium oxide anode resists carbon deposition anode material with composition xSr 0.88 Y 0.08 TiO 3 -(1-x)CeO 2 (x=0.5).

[0032] The preparation method is similar to Example 1, with Y 2 o 3 , SrCO 3 、TiO 2 As a raw material, after mixing and drying, it was calcined at 1150°C for 3 hours to obtain Sr 0.88 Y 0.08 SrTiO 3 Material. The prepared Sr 0.88 Y 0.08 TiO 3 Powder and CeO 2 The powder is mixed and dried according to 1:1, and the doped strontium titanate-cerium oxide composite anode material is prepared.

[0033] Will Sr 0.88 Y 0.08 TiO 3 -CeO 2The anode powder is mixed evenly in agate grinding with 1:1 weight ratio, 10% starch and screen printing solvent, and the prepared anode slurry is screen-printed on the YSZ electrolyte sheet, and sintered at 1350 ° C for 3 hours, and the cathode is prepared Method is with embodiment 1. The prepared single cell was assembled, and the perf...

Embodiment 3

[0035] Direct use of hydrocarbon fuel cells yttrium-doped strontium titanate-cerium oxide anode resists carbon deposition anode material with composition xSr 0.88 Y 0.08 TiO 3 -(1-x)CeO 2 (x=0.6).

[0036] The preparation method of doping strontium titanate is the same as that described in Example 2, the Sr 0.88 Y 0.08 TiO 3 -CeO 2 The anode powder was prepared with a weight ratio of 3:2 and 10% starch, and the screen printing solvent was mixed evenly in agate grinding, and the prepared anode slurry was screen printed on the YSZ electrolyte sheet, and sintered at 1350 ° C for 3 hours. The preparation method is the same as in Example 1. The prepared single cell was assembled, and the performance test of the single cell was performed with hydrogen / oxygen or methane / oxygen as fuel (see Table 1). The porosity of the anode was 55%, and its thickness was 120 μm.

[0037] Table 1. Battery performance comparison of three doped strontium titanate-cerium oxide composite anode ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com