Spiral-flow type electric dehydrator for crude oil

An electric dehydrator and swirling technology, applied in the direction of dehydration/demulsification by electricity/magnetic method, dehydration/demulsification by mechanical method, etc., can solve the problem of heavy maintenance workload, high operating noise and poor dehydration effect of high-speed rotating parts. and other problems, to achieve the effect of long service life, improved efficiency and rapid dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with specific examples and accompanying drawings.

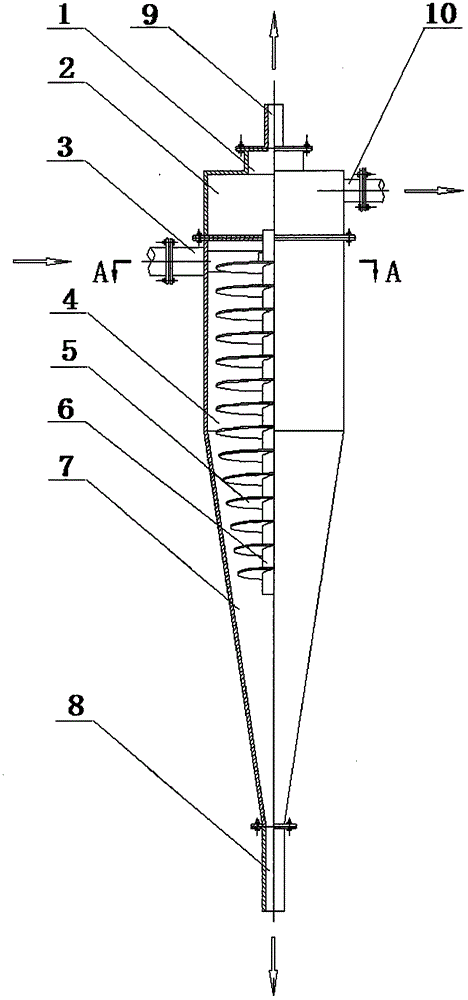

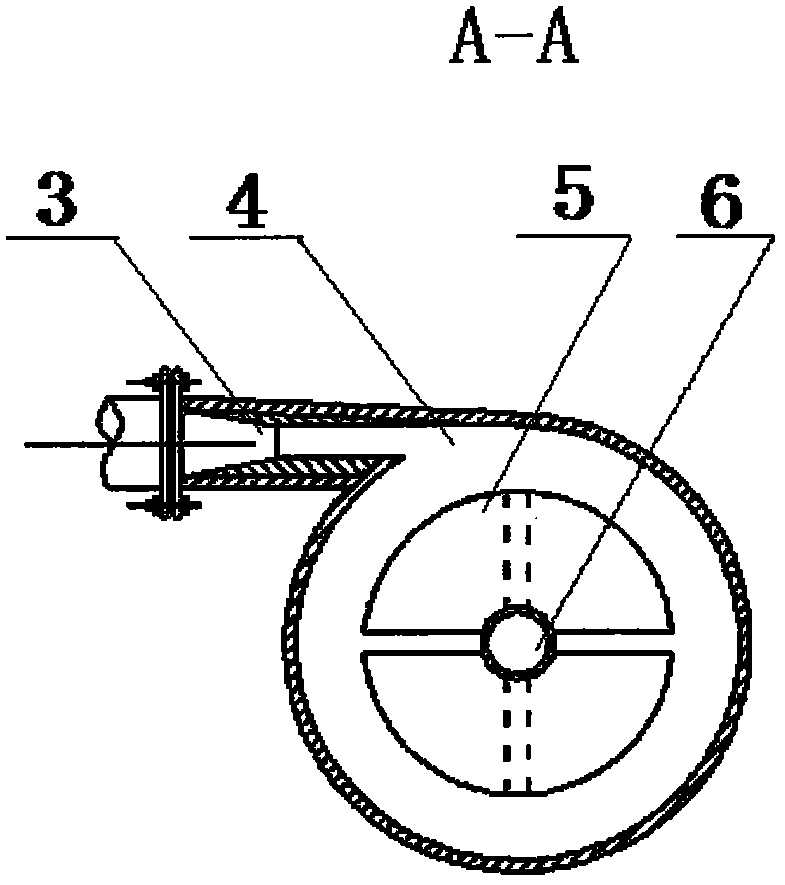

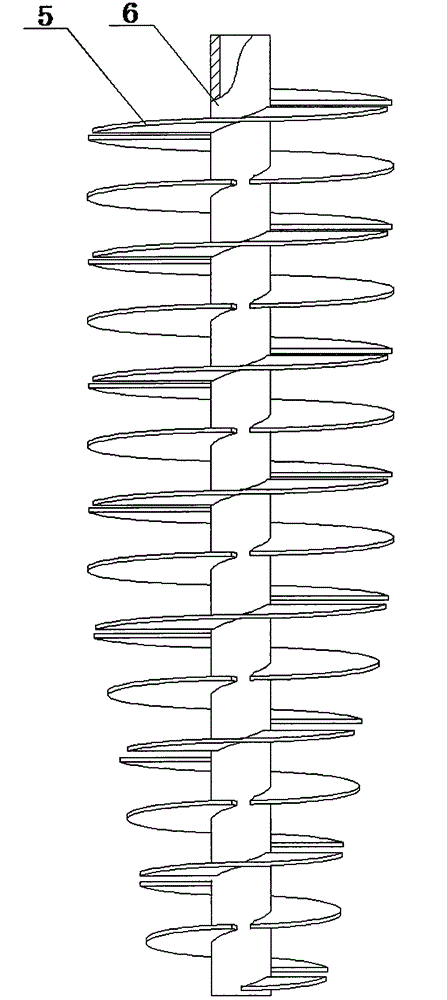

[0023] Such as figure 1 , figure 2 , image 3 As shown, a cyclone electric dehydrator for crude oil includes a gas collection chamber 1, an oil collection chamber 2, an oil inlet pipe 3, a cylindrical section 4, an electrode plate 5, an oil overflow pipe 6, a conical section 7, and a water discharge pipe 8. Exhaust pipe 9 and dehydrated oil discharge pipe 10, the exhaust pipe 9, gas collection chamber 1, oil collection chamber 2, cylindrical section 4, conical section 7 and dehydration water discharge pipe 8 are coaxial from top to bottom in sequence line connection;

[0024] The oil inlet pipe 3 communicates with and is tangent to the cylindrical section 4 at the upper end of the cylindrical section 4; the upper end of the cylindrical section 4 is connected to the oil collection chamber 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com