Offsetpress

A technology of offset presses and racks, applied in printing presses, rotary presses, printing and other directions, can solve the problems of adverse effects of printing patterns, affecting printing clarity, printing quality degradation, etc., to reduce ink splash and improve printing. quality, the effect of reducing ink scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

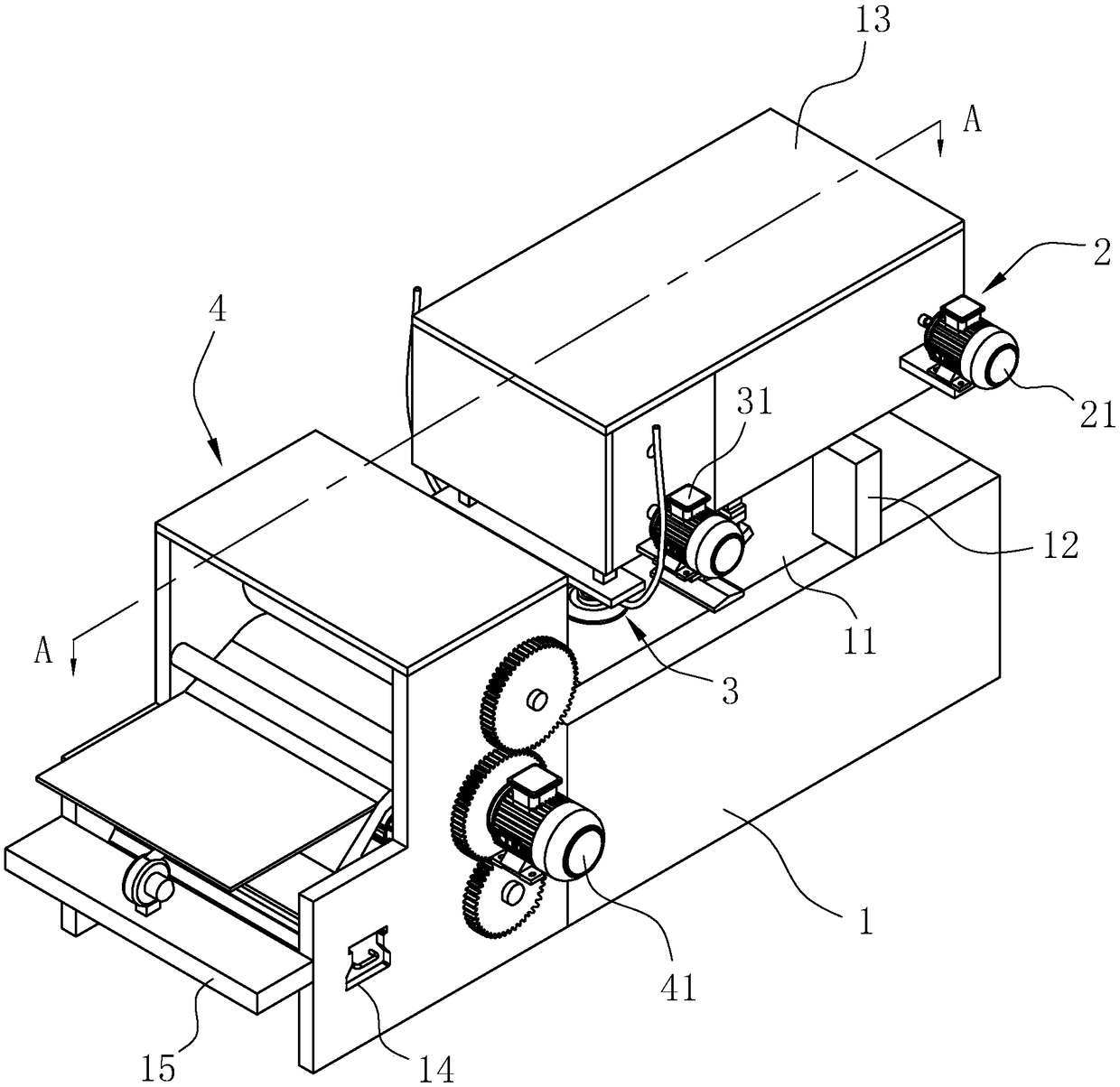

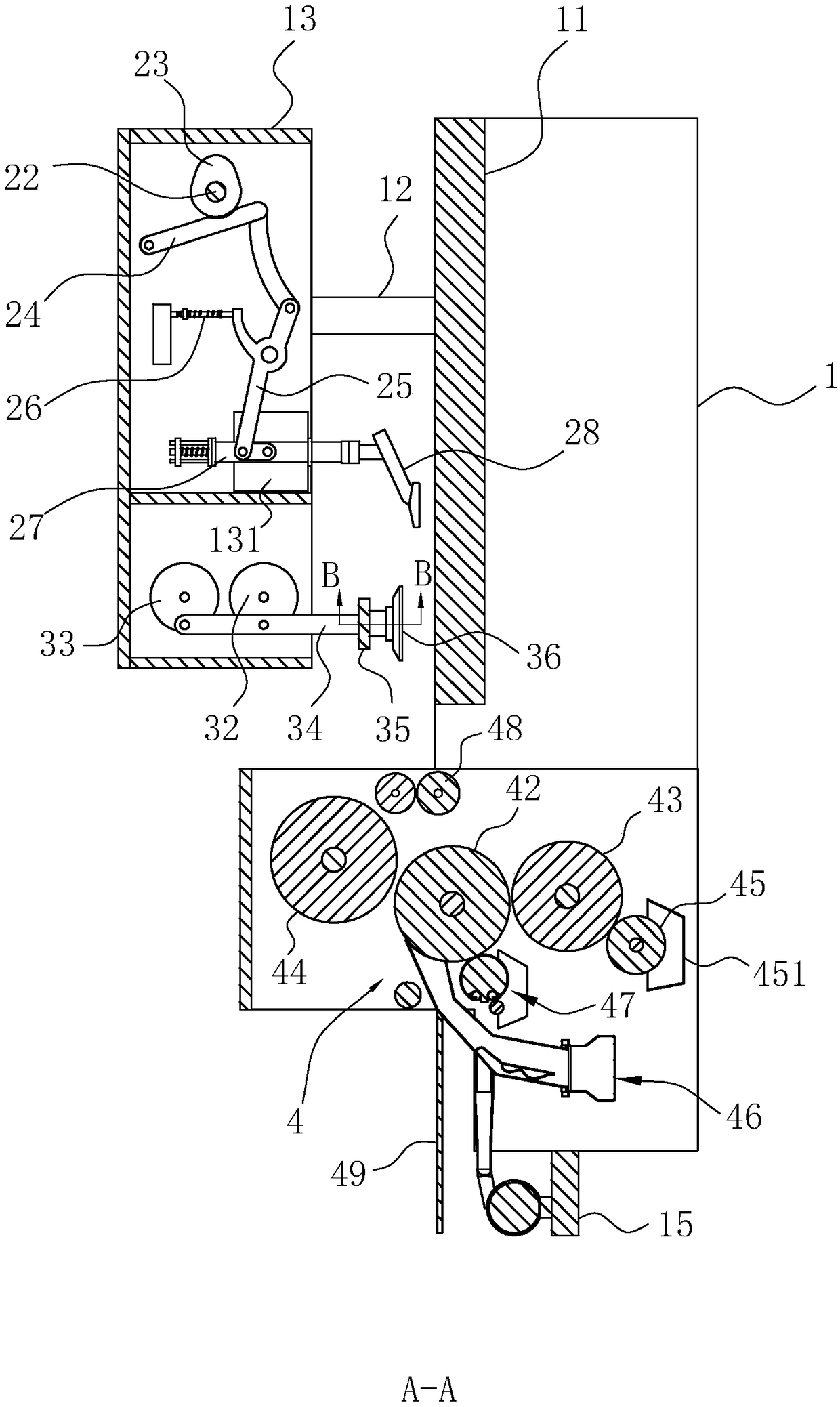

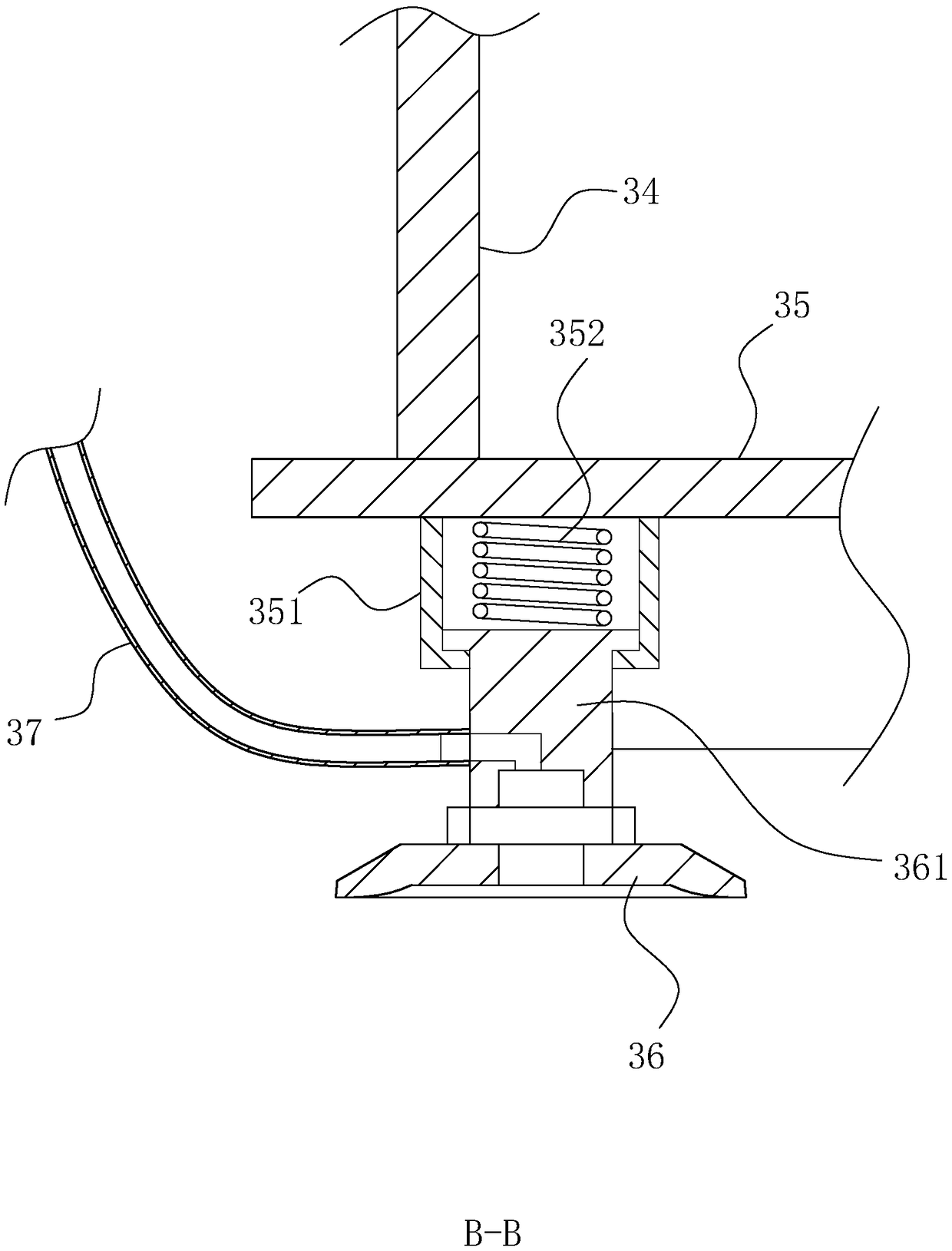

[0043] Embodiment: a kind of offset printing machine, as figure 1 and figure 2 As shown, a frame 1 is included, and a placement table 11 is fixed on the top of one end of the frame 1, and a paper pressing device 2, a suction cup device 3 and a printing device 4 are sequentially installed on the frame 1 from one end of the placement table 11 to the other end. , the stacked paper is placed on the placement table 11 and pressed by the paper pressing device 2, the suction cup device 3 sucks up the uppermost layer of paper and moves it to the printing device 4, and the paper passes through the printing device 4 to be printed with the required graphics .

[0044] refer to figure 1 and figure 2 , Both sides of the workbench 11 are fixedly supported by a dust cover 13 through the pillars 12, and the paper pressing device 2 and the sucker device 3 are installed in the dust cover 13.

[0045] Paper press device 2 comprises the paper press motor 21 that is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com