CNC machining equipment for mobile phone battery cover plate and working method of CNC machining equipment

A technology for mobile phone batteries and processing equipment, applied in lighting and heating equipment, cleaning methods using liquids, cleaning methods and utensils, etc. Cover pollution and other problems, to improve the processing effect, ensure the drying effect, and avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

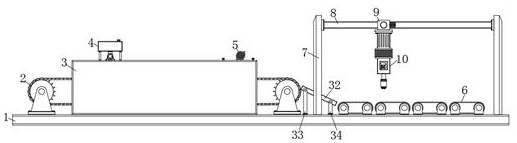

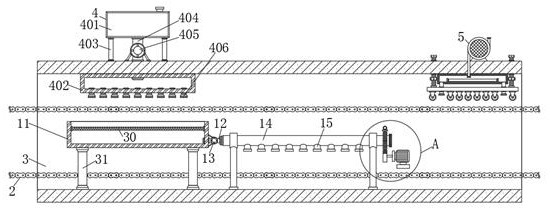

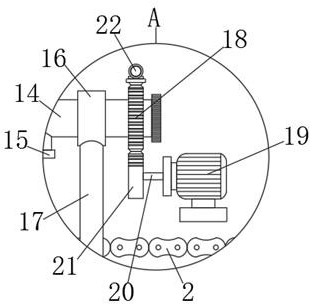

[0051] Such as Figure 1-5 Shown, the working method of the CNC processing equipment of this mobile phone battery cover comprises the following steps:

[0052] Step 1: Place the mobile phone battery cover to be processed on the conveying chain, start the first drive motor to drive the conveying roller to rotate, and transport the mobile phone battery cover from one side of the installation frame 3 to the other through the conveying chain;

[0053] Step 2: When the mobile phone battery cover plate is conveyed on the conveying chain, start the second pressure pump 405 to pump the cleaning liquid in the water tank 401 into the inside of the spray box 402 through the straight pipe 404, and pass through a plurality of second nozzles 406 to The cleaning liquid is sprayed on the mobile phone battery cover plate on the chain surface to clean the mobile phone battery cover plate. The cleaning liquid and solid impurities on the mobile phone battery cover plate and the conveying chain dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com