Preparation method for photoelectric device

A technology for optoelectronic devices and light sources, applied in electrical components, semiconductor devices, circuits, etc., can solve problems affecting crystal growth quality, surface contamination, surface defects, etc., to improve free carrier concentration and mobility, and avoid surface defects. , the effect of improving the efficiency of the active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

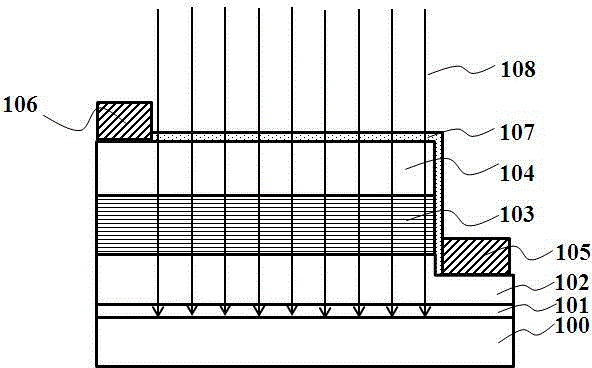

[0022] Such as figure 1 As shown, a schematic cross-sectional view of a preparation method of a light-emitting diode device, including the following steps:

[0023] (1) A substrate 100 is provided, and the substrate is selected from Al 2 o 3 , SiC, Si or GaN, Al is preferred in this embodiment 2 o 3 Substrate;

[0024] (2) After the substrate 100 is loaded into the reaction chamber and before growing the epitaxial layer, UV treatment is performed on the substrate. The UV light source is UVLED, and the UVLED treatment time is 0.1-10 min. The UVLED wavelength is 1-380nm. The light intensity is 0.1~1 000 000 mW / cm 2 ;

[0025] (3) Growing a buffer layer 101 on the UVLED-treated substrate 100, the buffer layer 101 is a gallium nitride (GaN) and / or aluminum nitride (AlN) layer or any combination thereof, with a thickness of 5-50 nm , UV treatment is carried out simultaneously during the growth process of the buffer layer 101, the UV light source is UVLED, the wavelength of U...

Embodiment 2

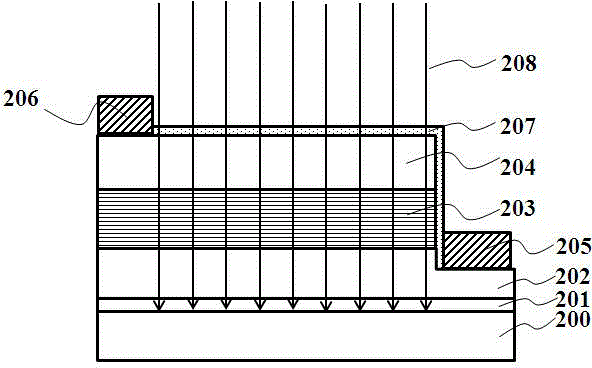

[0032] Such as figure 2 As shown, a schematic cross-sectional view of a preparation method of a solar cell device, comprising the following steps:

[0033] (1) A substrate 200 is provided, and the substrate is selected from Al 2 o 3 , SiC, Si or GaN, Al is preferred in this embodiment 2 o 3 Substrate;

[0034] (2) After the substrate 200 is loaded into the reaction chamber and before growing the epitaxial layer, UV treatment is performed on the substrate, the UV treatment time is 0.1-10 min, the UV light source is UVLED, and the UVLED wavelength is 1-380 nm, The light intensity of UV LED is 0.1~1 000 000 mW / cm 2 ;

[0035](3) Growing a buffer layer 201 on the UVLED-treated substrate 200, the buffer layer 201 is a gallium nitride (GaN) and / or aluminum nitride (AlN) layer or any combination thereof, with a thickness of 5-50 nm , UV treatment is carried out simultaneously during the growth process of the buffer layer 201, the UV light source is UVLED, the wavelength of UV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com