Paint spraying process of intermediate toothed plate

An intermediate tooth plate and paint technology, which is applied in the coating, the device for coating liquid on the surface, the pretreatment surface, etc., can solve the problem of the imperfect spraying process of the intermediate tooth plate, the disadvantage of the enterprise, and the inability to guarantee the spraying quality of the intermediate tooth plate, etc. problem, to ensure the effect of paint spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

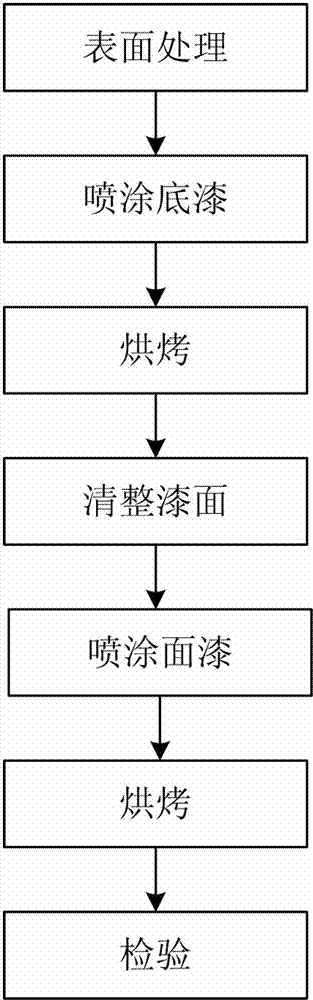

[0019] Such as figure 1 As shown, a kind of intermediate gear plate paint spraying process described in the embodiment of the present invention comprises the following steps:

[0020] 1) Surface treatment: oil removal, rust removal and dust removal;

[0021] When degreasing the intermediate tooth plate, use the mixed treatment liquid of 401 degreasing agent and water, the mass ratio of 401 degreasing agent: water is 1:10, and use different degreasing methods according to the different pollution conditions of the intermediate tooth plate method:

[0022] a. For local areas (the area of oil stains is less than 30%), use a brush to directly dip the cleaning liquid to scrub, and there will be no oil stains on the surface after cleaning; the cleaning liquid should flow when cleaning, and the sediment generated during use should be cleaned in time, otherwise the cleaning effect will be reduced. Not meeting the requirements.

[0023] b. When the area is large (the oily area is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com