High-precision and pollution-free semiconductor wafer cleavage method

A semiconductor and pollution-free technology, applied in the field of high-precision and pollution-free semiconductor wafer cleavage, can solve problems such as difficult to clean and affect the quality of semiconductor wafers, and achieve the effect of improving chip quality and yield, and surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

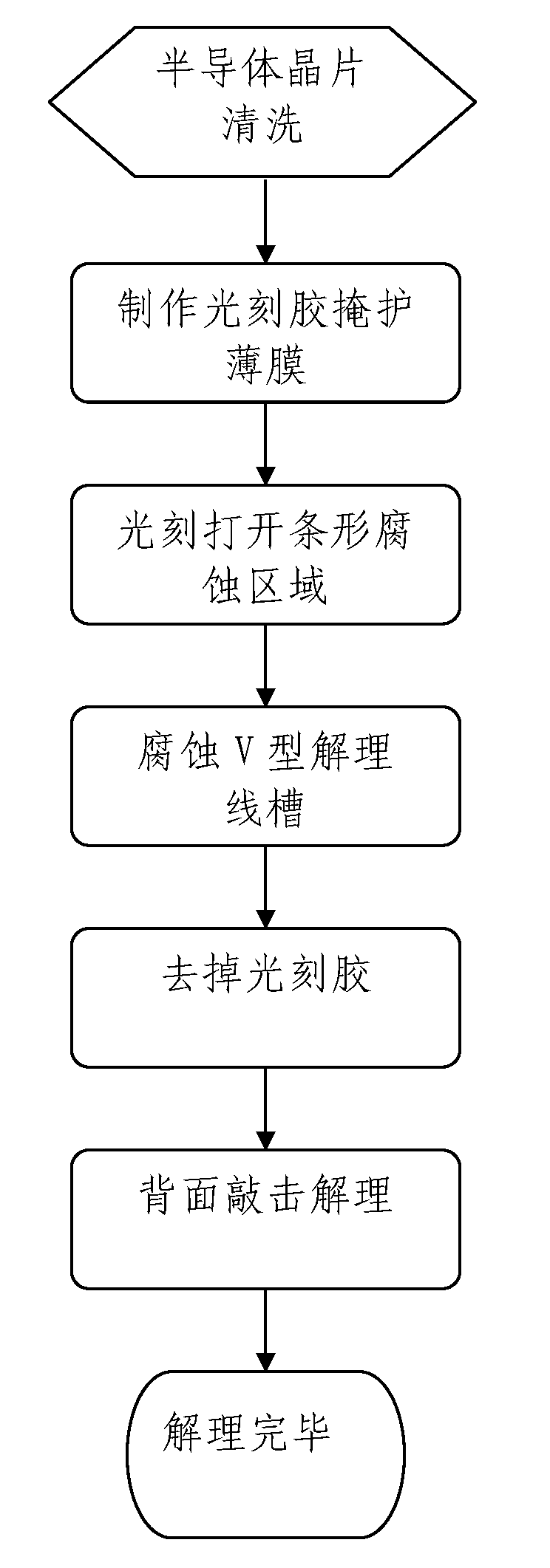

[0025] The present invention proposes a high-precision and pollution-free semiconductor wafer cleavage method. As shown in FIG. The relative position of the back side of the cleavage line groove is knocked, so that the semiconductor wafer 1 is divided along the V-shaped cleavage line groove. As shown in Figure 2-Figure 8, it specifically includes the following steps:

[0026] Step 1: As shown in FIG. 2 , the semiconductor wafer 1 to be cleaved is cleaned and blown dry with dry and clean nitrogen.

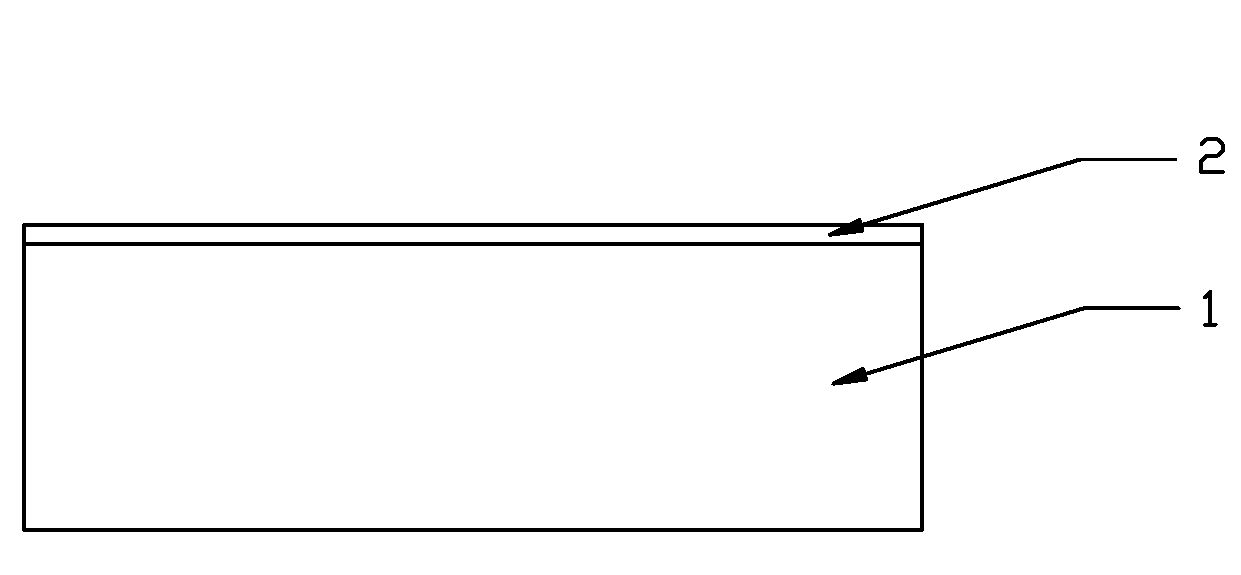

[0027] Step 2: Use photoresist 2 to make a protective film on the front side of semiconductor wafer 1. The photoresist 2 adopts ordinary positive photoresist, such as RZJ-304 positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com