Walnut shell separating equipment

A technology for separating equipment and walnut husks, applied in the directions of shelling, pod removal, chemical instruments and methods, etc., can solve the problems of reducing the integrity of pecan kernels, uneven strength of pecan shells, inaccurate hitting positions, etc. Achieve the effect of improving use security, high integrity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

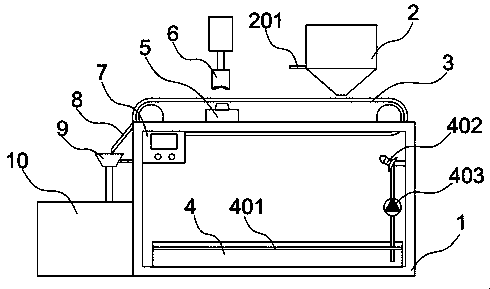

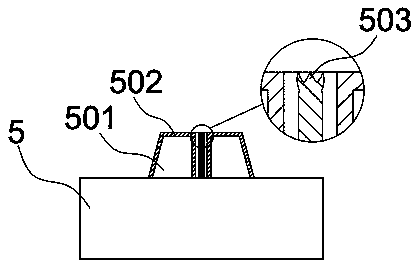

[0014] Such as figure 1 As shown, the walnut shell separation equipment includes a frame 1 on which a conveyor belt 3 is installed. The upper ends of the conveyor belt 3 are respectively provided with a feeding hopper 2 and a telescopic block 6, and the frame 1 at the discharge end of the conveyor belt 3 is provided with an inclined Guide plate 8, a collection box 10 is placed under the guide plate 8, a control panel 7 is placed on the upper part of the front of the frame 1, a telescopic block 6 is connected with a telescopic motor, and a supporting block 5 is provided on the inner side of the conveyor belt 3 directly below the telescopic block 6 , The bottom of the frame 1 below the conveyor belt 3 is provided with a collecting tank 1 with a built-in filter plate 401, and the collecting tank 1 is connected to the water pump 403 on the inner wall of the upper frame 1 through a water pipe, and the water pump 403 is connected to the frame 1 The nozzle 402 on the side wall is conne...

Embodiment 2

[0017] This embodiment further optimizes the solution based on embodiment 1:

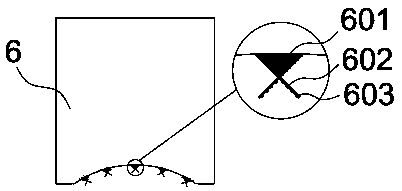

[0018] Such as figure 2 As shown, the bottom of the telescopic block 6 is provided with an arc-shaped concave surface, and a triangular pyramid-shaped broken shell 601 is evenly distributed in the concave surface. The top of the broken shell 601 is provided with two crossed buffer plates 602. The angle between the two buffer plates 602 and the three The cone-shaped broken shell 601 has the same cone apex angle, the arc-shaped bumps 603 are evenly distributed inside the buffer plate 602, the telescopic block 6 is driven by a telescopic motor, and the telescopic motor is controlled by the control panel 7 to control the telescopic block 6 Falling speed, the arc-shaped concave surface at the bottom of the telescopic block 6 can expand the contact area between the telescopic block 6 and the pecan, changing the phenomenon of excessively large contact force between the beating body and the pecan in the prior ...

Embodiment 3

[0022] Example 3: When the walnut husk separating equipment of the present invention is actually used: first select the type of walnut to be processed through the control panel 7. In this example, select pecan processing, select the transmission speed of the conveyor 3 and other parameter settings, and turn on the sterilization lamp 201 , Pour the freshly fried pecans into the hopper 2 as the pecans are transferred to the support block 5. The telescopic block 6 is knocked down on the pecans through the telescopic motor, crushing the pecan shells, and transporting the broken pecans When the end of the conveyor belt 3 falls into the buffer 9 through the guide plate 8, the broken pecans roll down in the buffer 9 and promote the separation of shells and kernels. The pecans that finally fall into the collection box 10 basically complete the shells and kernels. Separate and manually pick up the pecan shells to obtain complete pecan kernels. When the pecan processing is completed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com