CuPd alloy nanocrystal preparation and component regulation and control method

An alloy nanocrystal, mixed liquid technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the atomic percentage of Cu and Pd cannot be further regulated, and the atomic percentage of Cu and Pd cannot be controlled. , increase the complexity of product extraction, etc., to achieve the effect of retaining its own properties, improving product purity, and ensuring surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

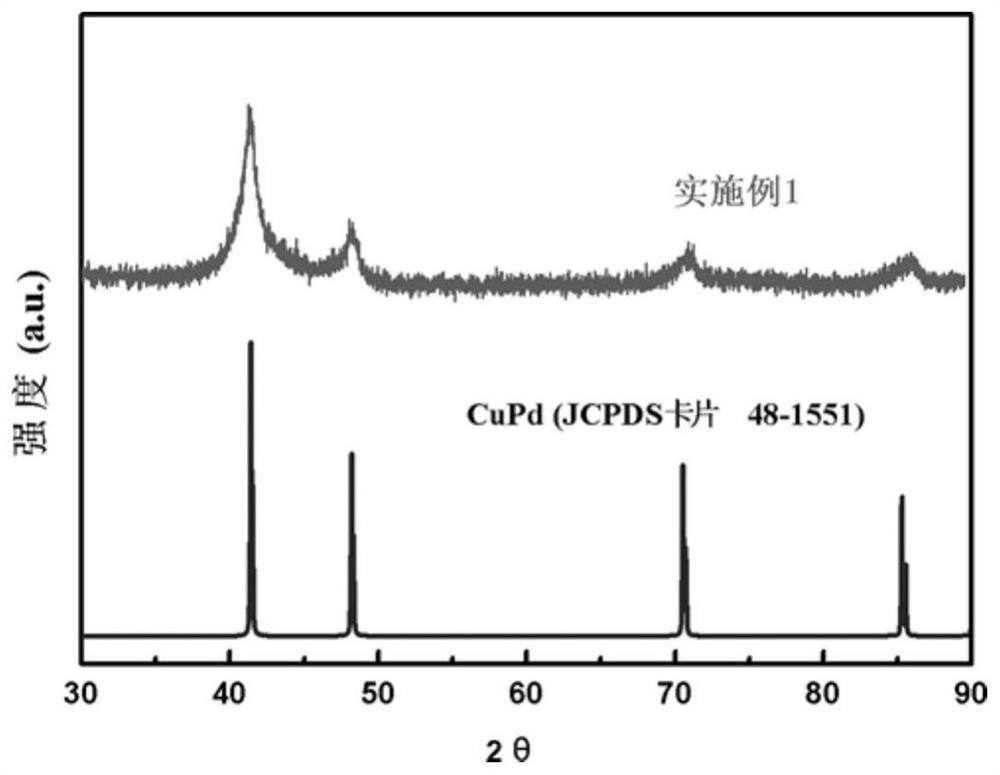

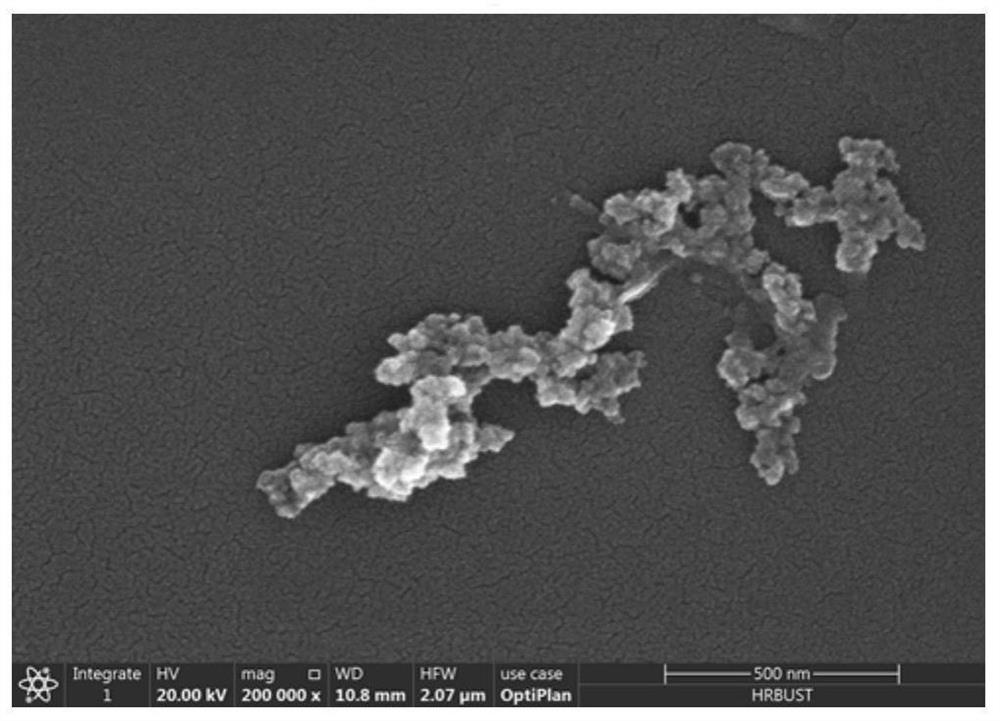

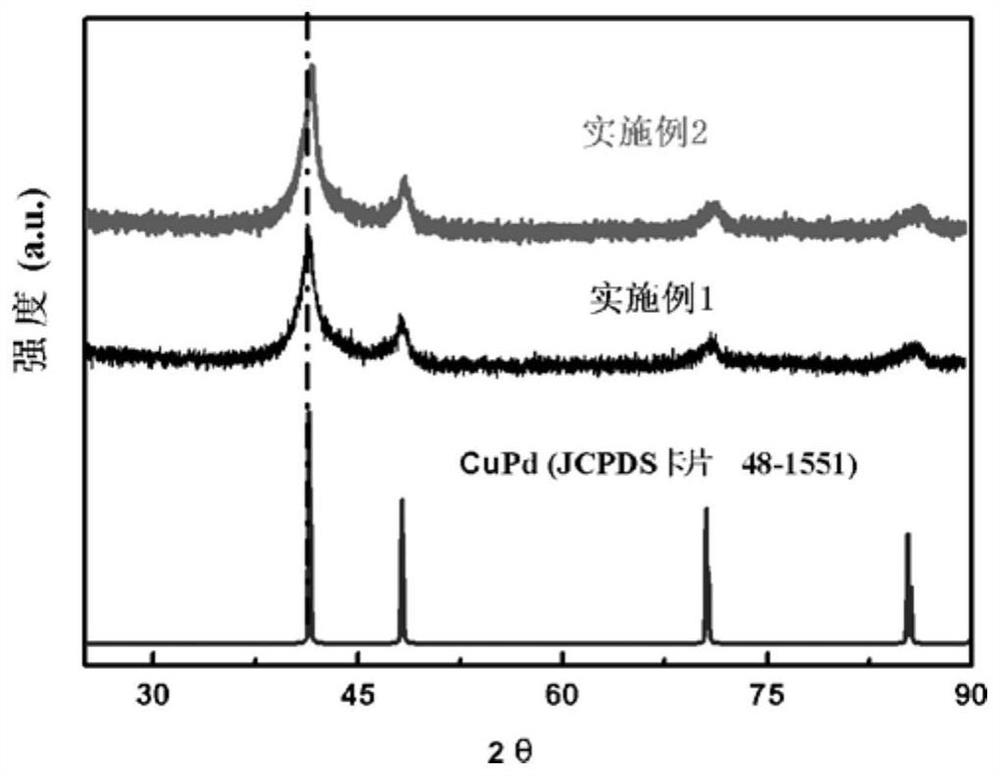

[0034] Embodiment 1: Preparation 1 of high-purity CuPd nanocrystals

[0035] 1) Take copper chloride as the solute and deionized water as the solvent, configure 19 ml of copper chloride solution with a concentration of 15 mmol / L, add 150 mg of potassium chloride, stir evenly with a magnetic stirrer and place at 95 degrees Celsius , to obtain the mixed solution 1;

[0036] 2) Dissolving 0.05 mmol of palladium chloride powder in 5 ml of hydrochloric acid solution with a concentration of 0.1 mol / L, heated to 85 degrees Celsius to dissolve, and obtained mixed solution 2;

[0037] 3) Add the mixed solution 2 to the mixed solution 1, and stir at 95 degrees Celsius for 15 minutes to obtain the mixed solution 3;

[0038] 4) Add 6 ml of ascorbic acid with a concentration of 1.0 mol / L to the mixed solution 3, and stir rapidly at 95 degrees Celsius for 5 hours;

[0039] 5) The obtained product is separated by a centrifuge, first dispersed in deionized water and then ultrasonically cent...

Embodiment 2

[0041] Embodiment 2: the preparation 2 of high-purity CuPd nanocrystal

[0042] 1) Take copper chloride as the solute and deionized water as the solvent, configure 19 ml of copper chloride solution with a concentration of 15 mmol / L, add 150 mg of potassium chloride, stir evenly with a magnetic stirrer and place at 95 degrees Celsius , to obtain the mixed solution 1;

[0043] 2) Dissolving 0.05 mmol of palladium chloride powder in 2.5 ml of hydrochloric acid solution with a concentration of 0.1 mol / L, heated to 90 degrees Celsius to dissolve, and obtained mixed solution 2;

[0044] 3) Add the mixed solution 2 to the mixed solution 1, and stir at 95 degrees Celsius for 15 minutes to obtain the mixed solution 3;

[0045] 4) Add 6 ml of ascorbic acid with a concentration of 1.0 mol / L to the mixed solution 3, and stir rapidly at 95 degrees Celsius for 5 hours;

[0046] 5) The obtained product is separated by a centrifuge, first dispersed in deionized water and then ultrasonically...

Embodiment 3

[0049] Embodiment 3: Preparation 3 of high-purity CuPd nanocrystals

[0050] 1) Take copper chloride as the solute and deionized water as the solvent, configure 19 milliliters of copper chloride solution with a concentration of 15 mmol / L; add 150 mg of potassium chloride, stir evenly with a magnetic stirrer and place at 95 degrees Celsius , to obtain the mixed solution 1;

[0051] 2) Dissolving 0.1 mmol of palladium chloride powder in 5 ml of hydrochloric acid solution with a concentration of 0.1 mol / L, heated to 90 degrees Celsius to dissolve, and obtained mixed solution 2;

[0052] 3) Add the mixed solution 2 to the mixed solution 1, and stir at 95 degrees Celsius for 15 minutes to obtain the mixed solution 3;

[0053] 4) Add 6 ml of ascorbic acid with a concentration of 1.0 mol / L to the mixed solution 3, and stir rapidly at 95 degrees Celsius for 5 hours;

[0054] 5) The obtained product is separated by a centrifuge, firstly dispersed in deionized water and then ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com