High glaze ornamental double-component acrylic acid polyurethane antimicrobial paint

An acrylic polyurethane, decorative technology, used in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problem of limited antibacterial effect, poor gloss and fullness, and failure to reach high Glossy decorative coatings and other problems, to achieve the possible effects of reducing the number of disinfection, good adhesion, and reducing cross-contamination viruses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

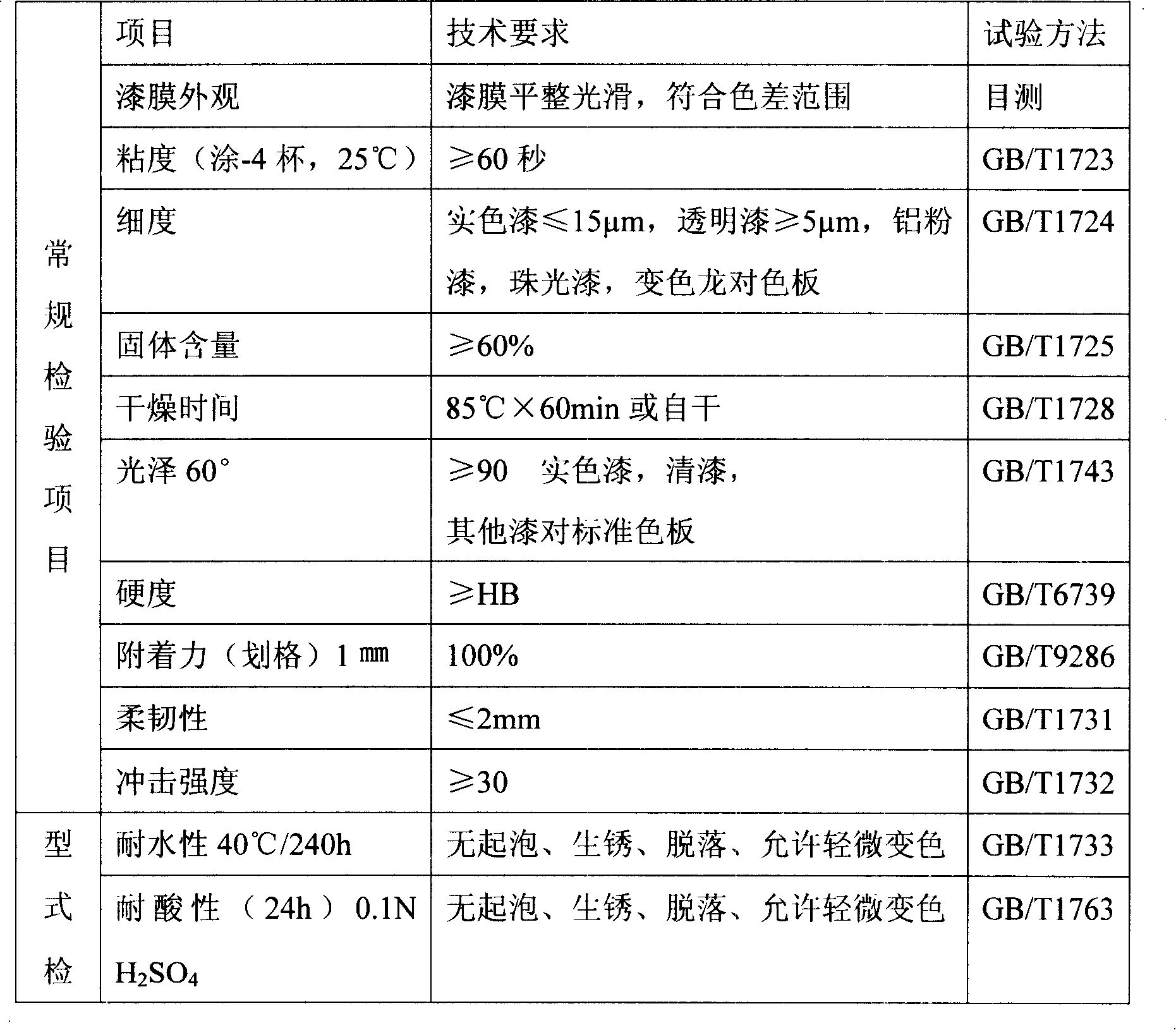

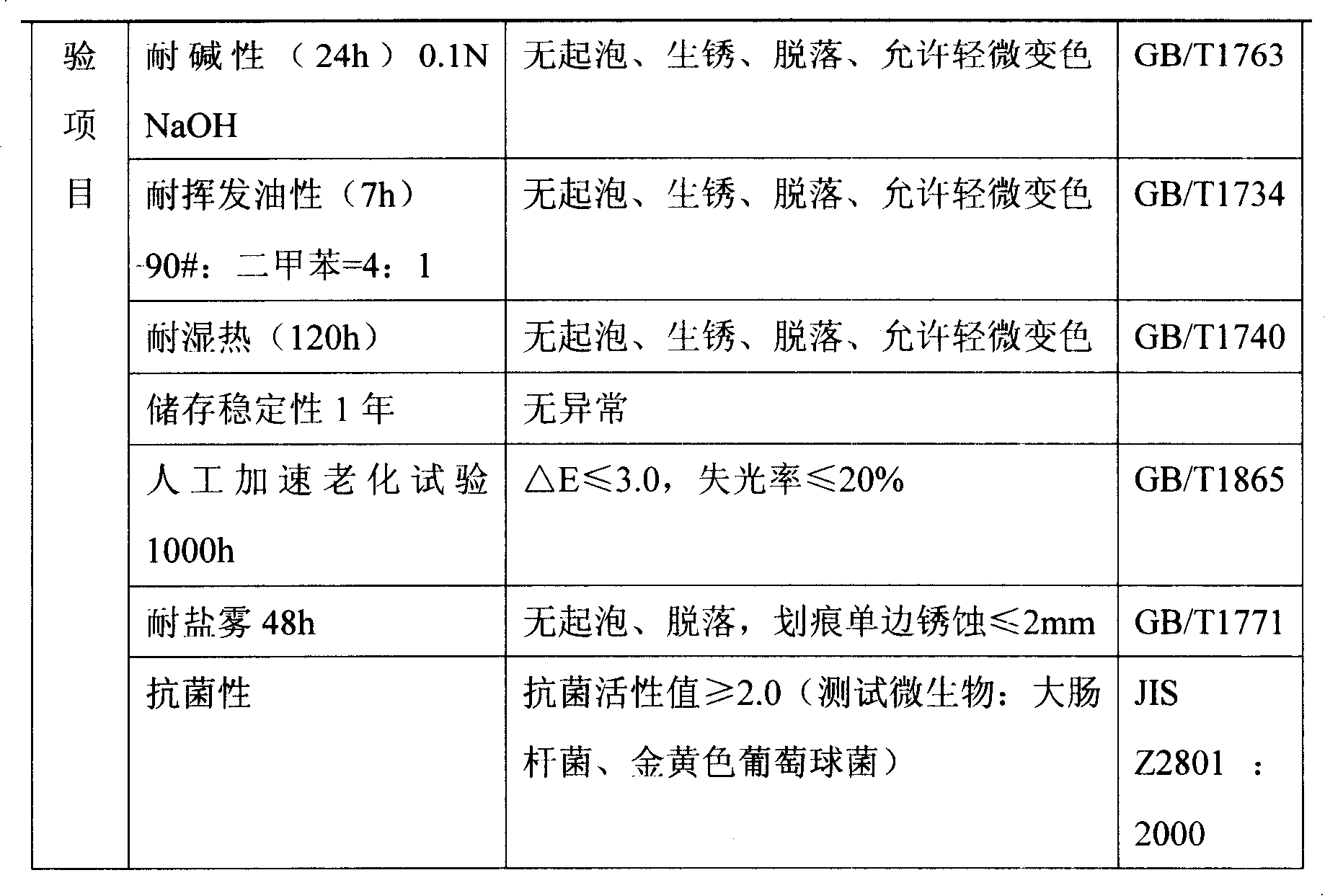

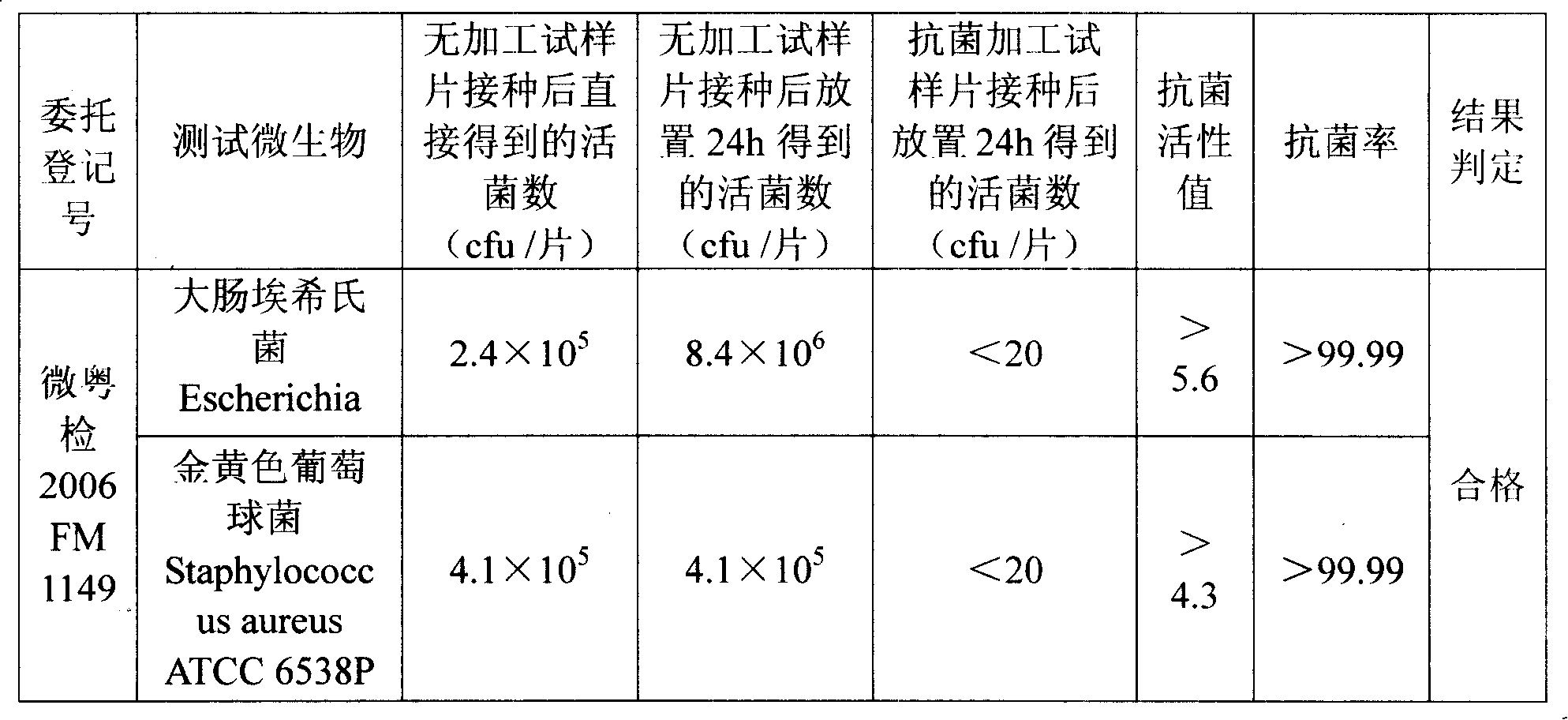

Image

Examples

Embodiment 1

[0025] A method for preparing high-gloss decorative two-component acrylic polyurethane antibacterial (varnish or silver paint). Take 80 parts of hydroxy acrylic resin, 4 parts of butyl acetate, 2 parts of xylene, 0.7 parts of leveling agent in proportion, add 3 parts of pretreated inorganic antibacterial agent, mix and stir evenly, and then adjust the viscosity with butyl acetate until the viscosity is qualified Prepare antibacterial varnish, or put in metallic glitter powder (pearl powder), the amount is 5%, stir evenly to prepare antibacterial glitter paint (silver paint), after confirming the color, perform performance inspection, packaging, and then perform antibacterial and heavy metal Content detection, that is, this product is obtained.

Embodiment 2

[0027] A method for preparing high-gloss decorative two-component acrylic polyurethane antibacterial (color paint). Take 40 parts of hydroxy acrylic resin, 8 parts of pigment, 4 parts of butyl acetate, 2 parts of xylene, 0.5 part of dispersant, mix and stir uniformly, pre-disperse, grind, and control the fineness. After the fineness is qualified, Add 35 parts of hydroxy acrylic resin and 0.3 parts of leveling agent. Stir until uniform. Pay attention to control the viscosity during the stirring process to obtain semi-finished color paste. To color the semi-finished color paste, add 3 parts of pretreated inorganic antibacterial agent. Adjust with butyl acetate until the viscosity is qualified, then stir evenly, after confirming the color, perform performance inspection, packaging, and finally perform antibacterial and heavy metal content detection to obtain the antibacterial paint finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com