A method of producing solid-state imaging device

A solid-state imaging device and solid-state imaging technology are applied in radiation control devices, semiconductor/solid-state device parts, electric solid-state devices, etc., which can solve problems such as poor flatness, inability to guarantee stiffness, narrow distance, etc., and achieve improved reliability. Transferability, improvement of stiffness, and damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

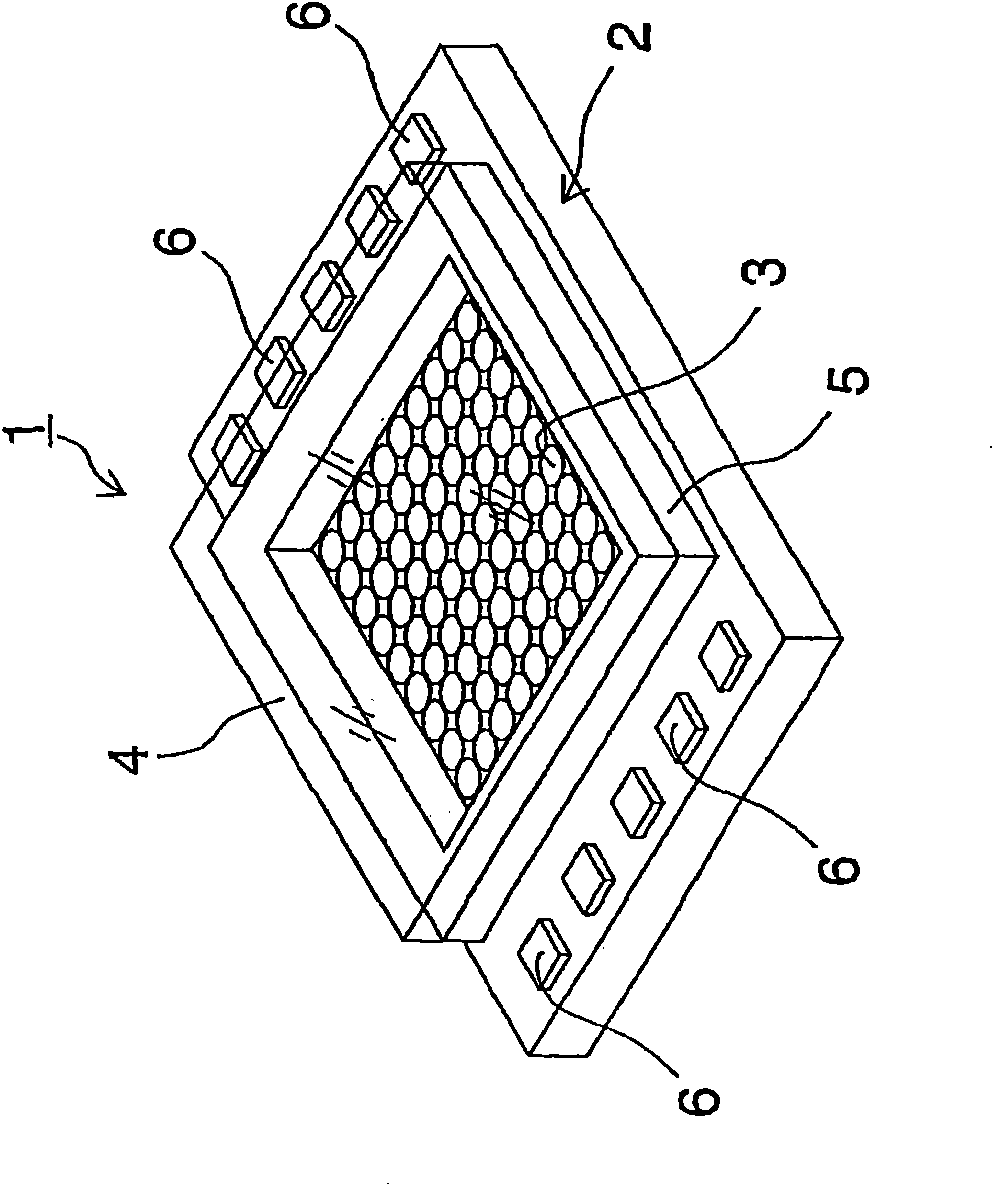

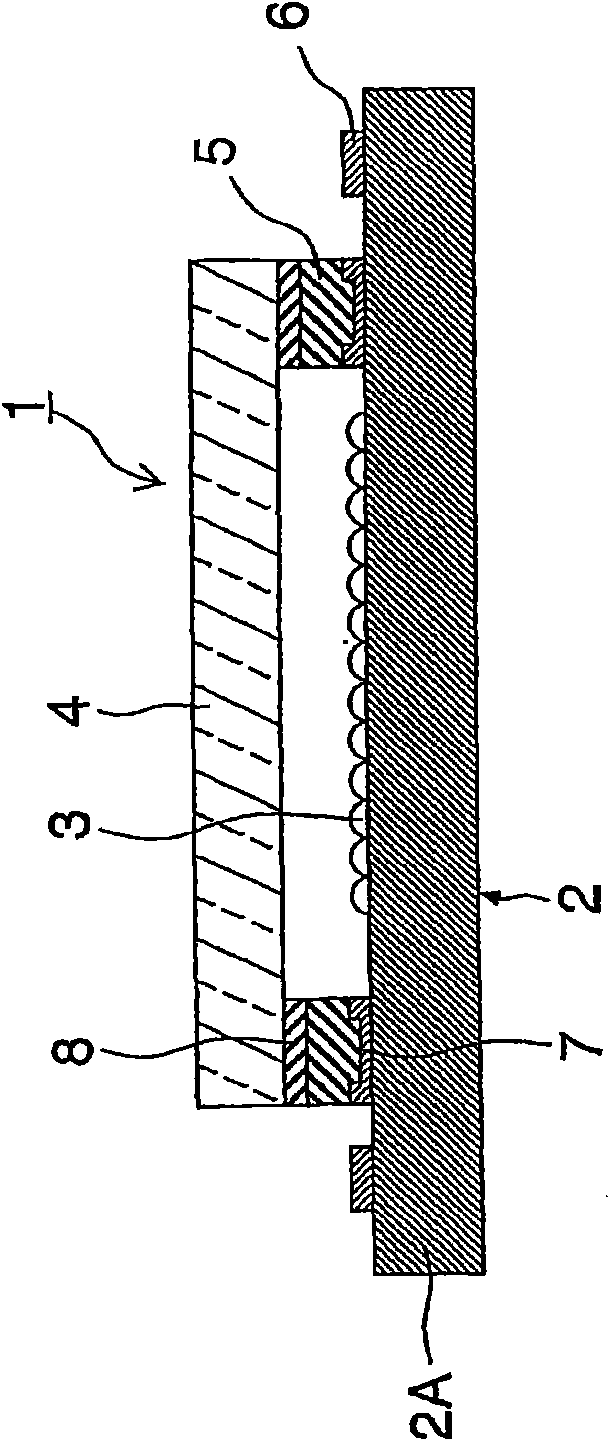

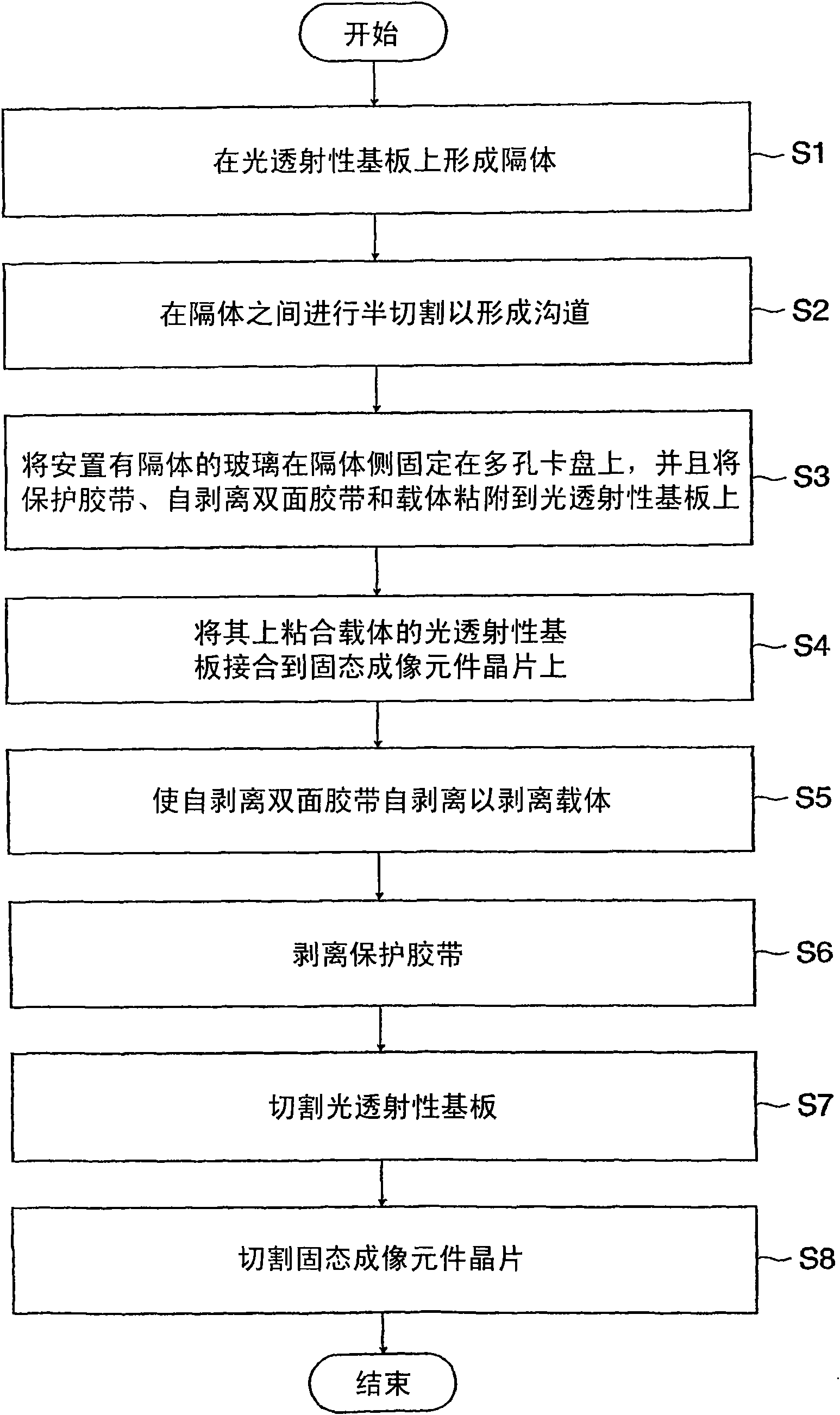

[0097] A specific example of a method of manufacturing a solid-state imaging device according to the present invention is described below. The reference numbers appearing below are used in figure 1 , 2 , 4 and those shown in 6.

[0098] Pyrex (registered trademark) glass of 8 inches and 300 μm thick was used as the light-transmitting substrate 10 . Spacers 5 having a height of 50 μm are formed on the light-transmitting substrate 10 .

[0099] Between the spacers 5, half-cut cutting was performed with a depth of 150 μm and 80 lines in the vertical and horizontal directions. A cutting device produced by DISCO Corporation was used for cutting. "UHP-1005M3 (ultraviolet peeling type)" manufactured by DENKIKAGAKU KOGYO KABUSHIKI KAISHA was used as a dicing tape. A resin-bonded grinding stone with an outer diameter of 55 mm, a width of 0.1 mm to 0.7 mm, and a grain size of #400 was used. The number of revolutions of the grindstone was 30000 rpm and the processing speed was 1 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com