Method for preparing efficient hydrolysis metal sulfide electrode material through one-step method

A metal sulfide and electrode material technology, applied in the direction of metal material coating process, electrode, electrode shape/type, etc., can solve the difficult to control shape and composition, increase electrical conductivity and mass transfer performance, electrical conductivity and mass transfer performance Poor problems, to achieve the effect of improving conductivity and electron transfer efficiency, improving catalytic performance, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

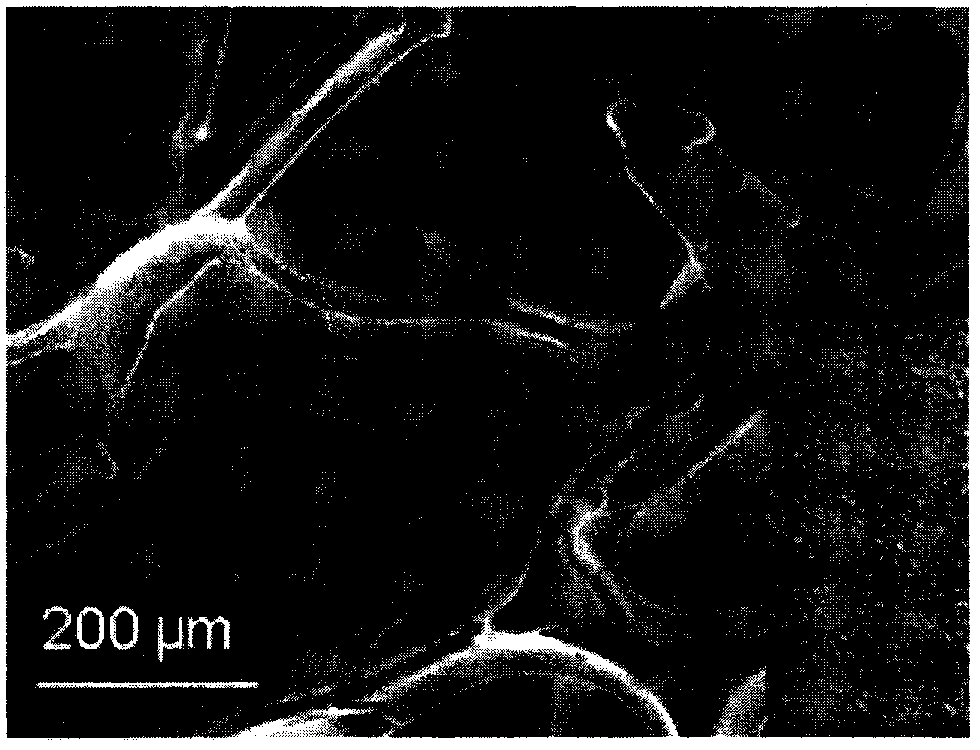

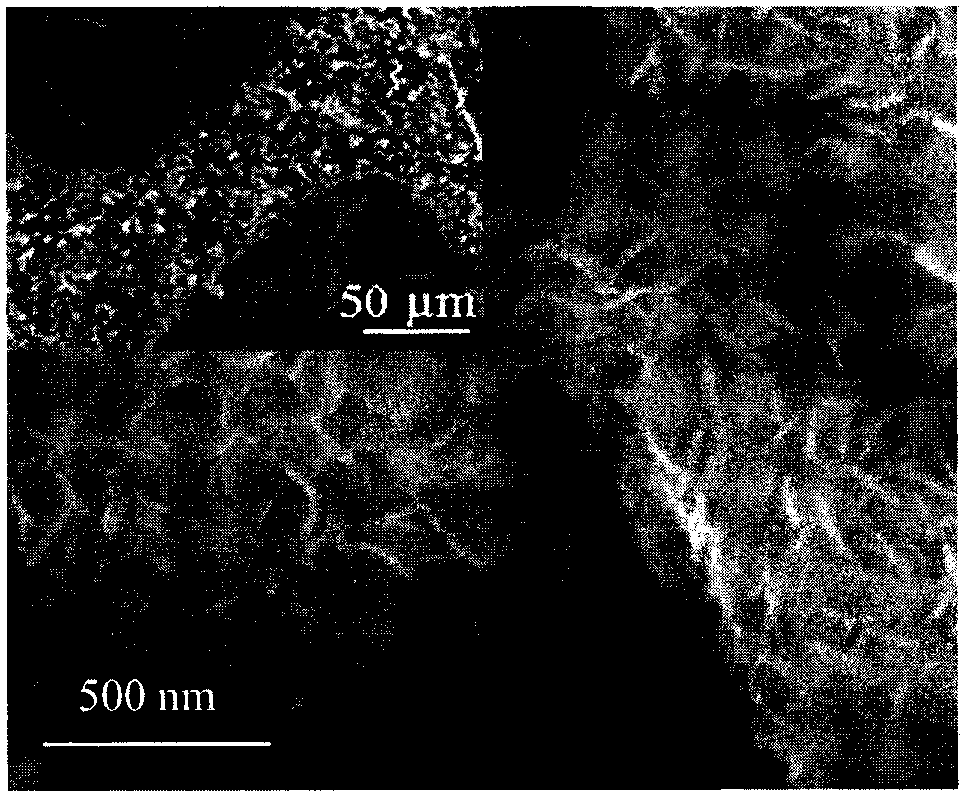

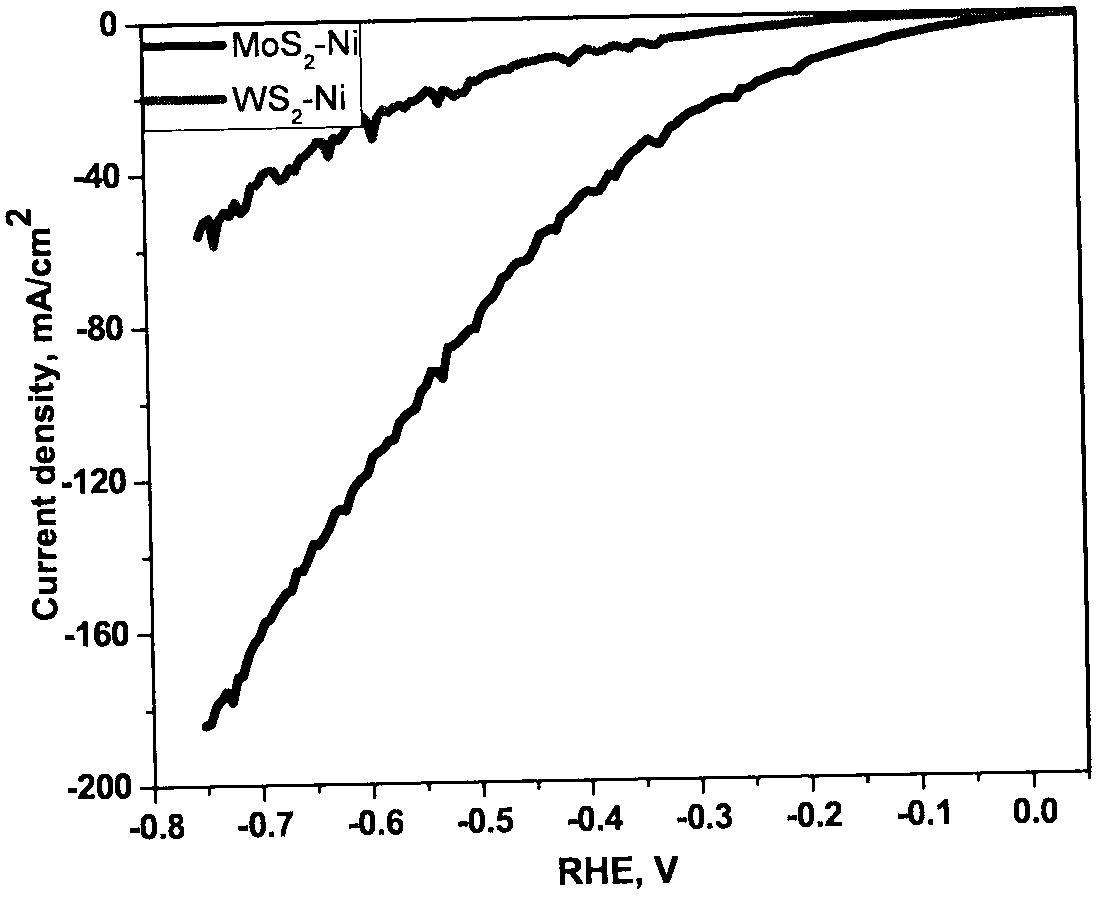

[0026] Clean the nickel foam (1.5cm×1.0cm×0.15cm) ultrasonically with 3M HCl solution for 30 minutes, and then use absolute ethanol, acetone and deionized water to ultrasonically clean the nickel foam for 15 minutes to ensure its surface is clean. Wrap a piece of nickel foam cleaned according to the above steps with polytetrafluoroethylene, and the exposed area is about 1cm 2 , immerse it in a 250mL Teflon-lined stainless steel reactor containing 20mL of the mixed solution (the mixed solution contains ethanol, deionized water, ammonium tetrathiomolybdate, and urea), and perform ultrasonic treatment for 30min, wherein ethanol and deionized The volume ratio of water is 1:1, ammonium tetrathiomolybdate and urea are respectively 0.1 g and 0.3 g. The mixed product was put into a sealed autoclave for hydrothermal operation, heated from room temperature to 170°C at a rate of 2°C / min, and kept for 6h. After the reaction, wait for the autoclave to cool down to room temperature, rinse ...

Embodiment 2

[0032] Clean the nickel foam (1.5cm×1.0cm×0.15cm) ultrasonically with 3M HCl solution for 30 minutes, and then use absolute ethanol, acetone and deionized water to ultrasonically clean the nickel foam for 15 minutes to ensure its surface is clean. Wrap a piece of nickel foam cleaned according to the above steps with a Teflon tape, and the exposed area is about 1cm 2 , immerse it in a 250mL Teflon-lined stainless steel reaction kettle containing 20mL of the mixed solution (the mixed solution contains ethanol, deionized water, WCl 4, urea), ultrasonic treatment for 30min, wherein the volume ratio of ethanol to deionized water is 1:1, WCl 4 and urea are 0.15g and 0.3g respectively. The mixed product was put into a sealed autoclave for hydrothermal operation, heated from room temperature to 180°C at a rate of 2°C / min, and kept for 6h. After the reaction, wait for the autoclave to cool down to room temperature, rinse the obtained sample with deionized water, and then dry it in an...

Embodiment 3

[0038] Controllable preparation of polycrystalline MoS by solid-state reaction 2 , mixed high-purity fine powder Mo (99.9%) with S (99.999%) in a suitable stoichiometric ratio, and thoroughly ground, then granulated in a sealed vacuum quartz tube, and heated from room temperature at a rate of 1 °C / min To 600 ℃, keep 120h. The nickel foam (1.5cm×1.0cm×0.15cm) was ultrasonically cleaned with 3M HCl solution for 30min, and then the nickel foam was ultrasonically cleaned with absolute ethanol, acetone and deionized water for 15min to ensure its surface was clean. MoS can be made by a simple one-step hydrothermal operation 2 Nanoflower arrays are grown on nickel foam supports. Wrap a piece of nickel foam with Teflon tape, and the exposed area is about 1cm 2 , and then immersed it in a solution containing ethanol (20 mL) and MoS 2 (0.2g) powder in a polytetrafluoroethylene-lined stainless steel reactor for 30min. Then carry out hydrothermal operation in a sealed autoclave, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com