Method for igniting a fuel-air mixture in a combustion chamber of an internal combustion engine by corona discharge

An air mixture and combustion chamber technology, applied in electrical components, spark ignition devices, circuits, etc., can solve problems such as unsatisfactory combustion, achieve the effect of preventing undesired combustion and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

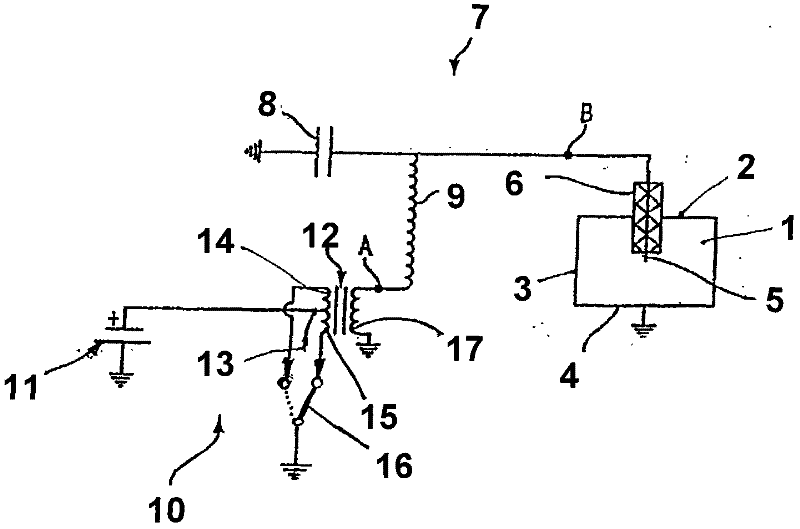

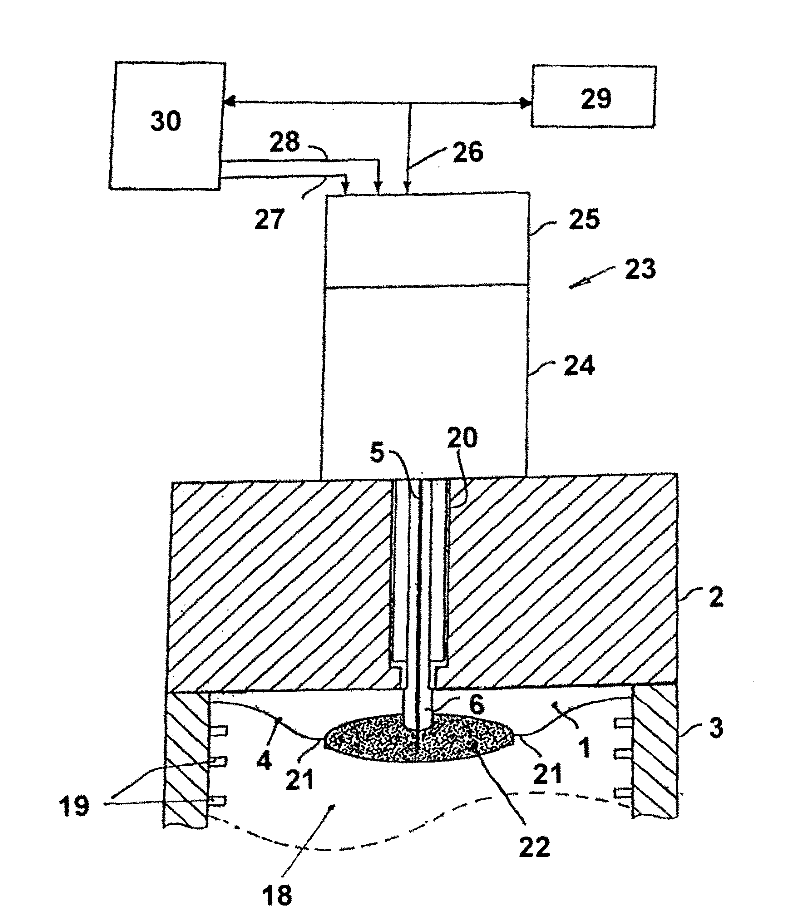

[0052] figure 1 Shown is a combustion chamber 1 delimited by walls 2, 3, 4 at ground potential. Ignition electrode 5 , which is surrounded along part of its length by an insulator 6 , extends from above into combustion chamber 1 and is guided by this insulator through upper wall 2 into combustion chamber 1 in an electrically insulated manner. The ignition electrode 5 and the walls 2 to 4 of the combustion chamber 1 are part of a series oscillating circuit 7 which also includes a capacitor 8 and an inductor 9 . Of course, the series oscillating circuit 7 may also contain further inductors and / or capacitors, as well as other components known to those skilled in the art as possible components of a series oscillating circuit.

[0053] The high-frequency generator 10 is provided for exciting the oscillating circuit 7 and contains a DC voltage source 11 and a transformer 12 as a DC / AC converter, the latter having a center tap 13 on the primary side so that the two primary windings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com