Gas-phase reaction device and preparation method of dicyclohexylamine

A gas-phase reaction and dicyclohexylamine technology, which is applied in the preparation of amino compounds by condensation/addition reactions, chemical instruments and methods, and the preparation of organic compounds, etc. It is fully utilized and the reaction effect becomes poor, so as to achieve the effect of strengthening the reaction yield, preventing accumulation, and reducing the overheating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

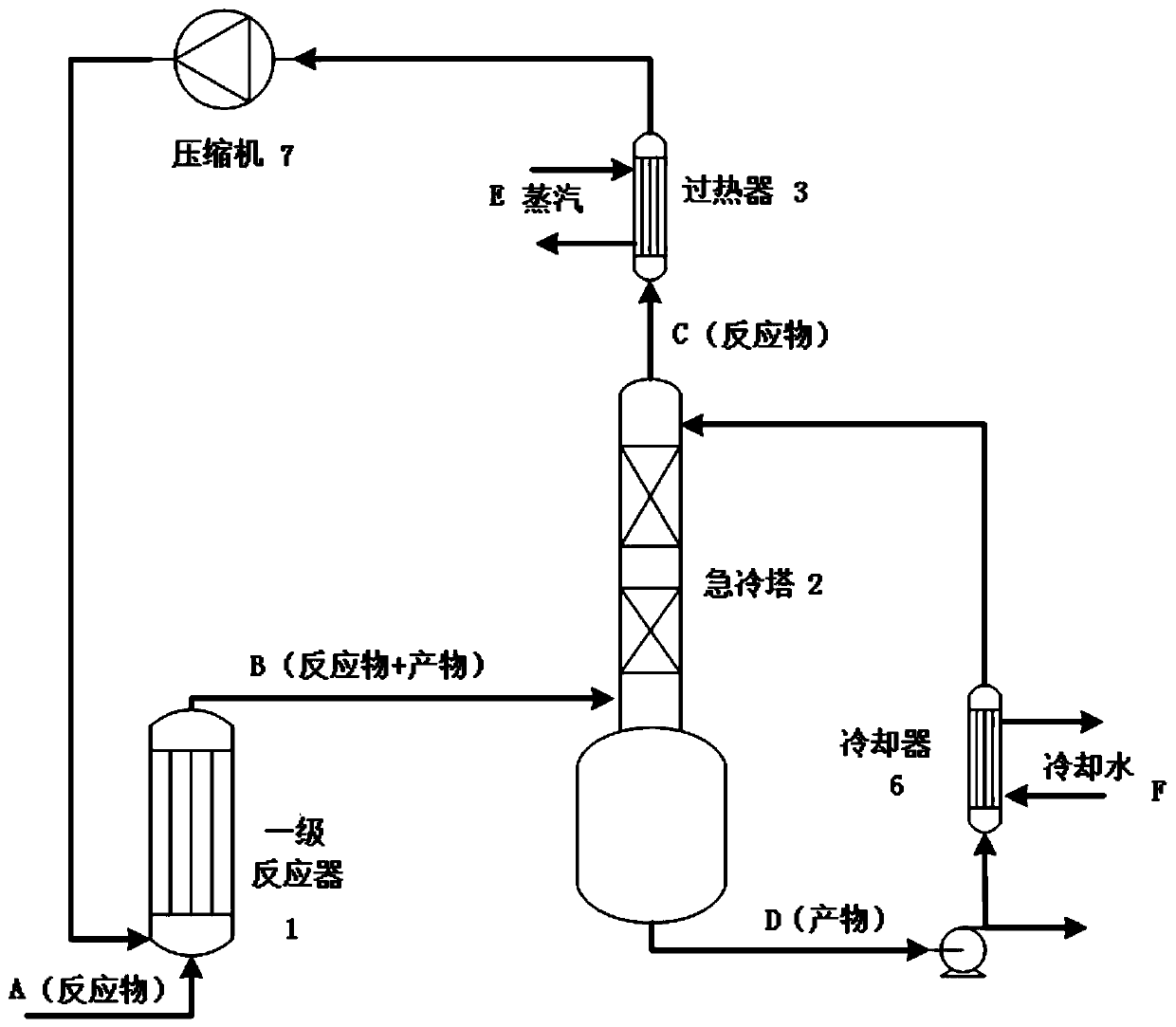

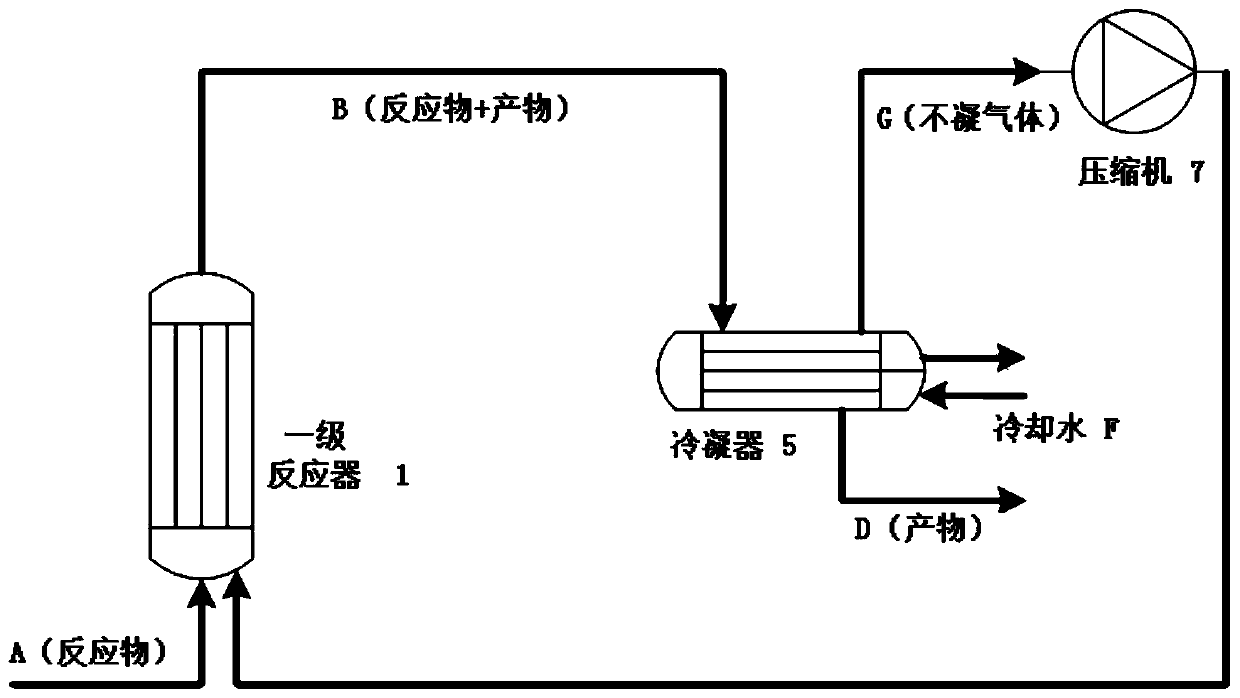

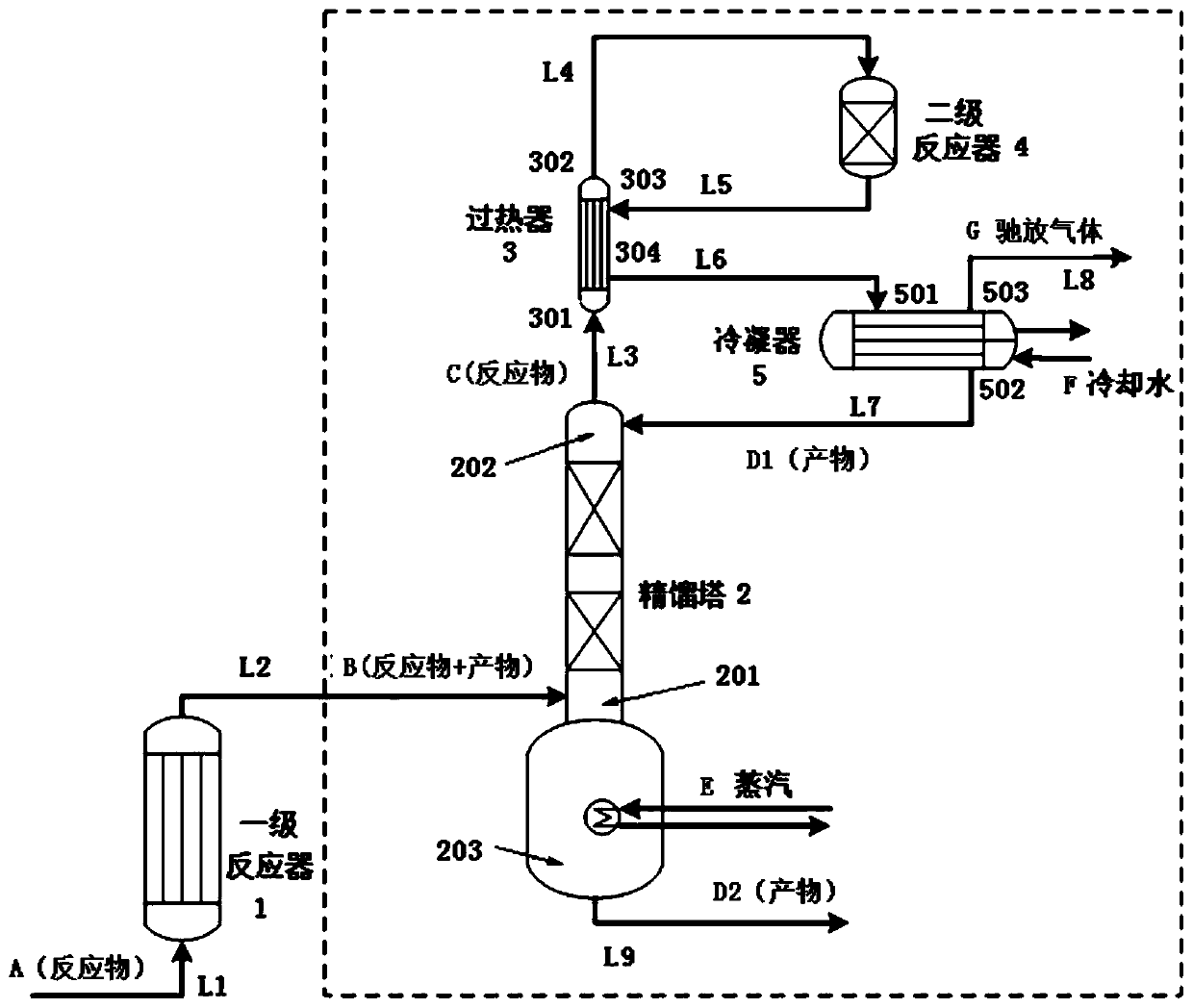

[0063] Such as Figure 4 Shown, in the present embodiment 1, improve the yield of dicyclohexylamine by reactive distillation method.

[0064] The primary gas-phase reactor 1 is a tubular fixed-bed reactor (filled with precious metal palladium) of DWE in Germany, using boiler water to remove heat, with a diameter of 1000 mm and a length of 2000 mm. The secondary gas phase reactor 4 is a stacked bed fixed bed reactor filled with precious metal palladium, with a diameter of 500mm and a length of 1000mm, and the manufacturer is DWE in Germany. The rectification tower is an ordinary packed tower (Shandong Zhongsheng Pharmaceutical Equipment Co., Ltd.), with 15 theoretical plates.

[0065] Dicyclohexylamine can be prepared by hydrodeamination of aniline or by deamination of cyclohexylamine.

[0066] 1) The initial reactant aniline and hydrogen A are delivered to the primary gas phase reactor 1 for gas phase reaction, wherein the reaction temperature is about 150° C., and the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com