Volatile rust preventive oil

A gas-phase anti-rust and gas-phase corrosion inhibitor technology, applied in the field of lubricating oil, can solve the problems of rust, easy oxidation, and inaccessibility of anti-rust oil, etc., to reduce costs, save labor and materials, and clean the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

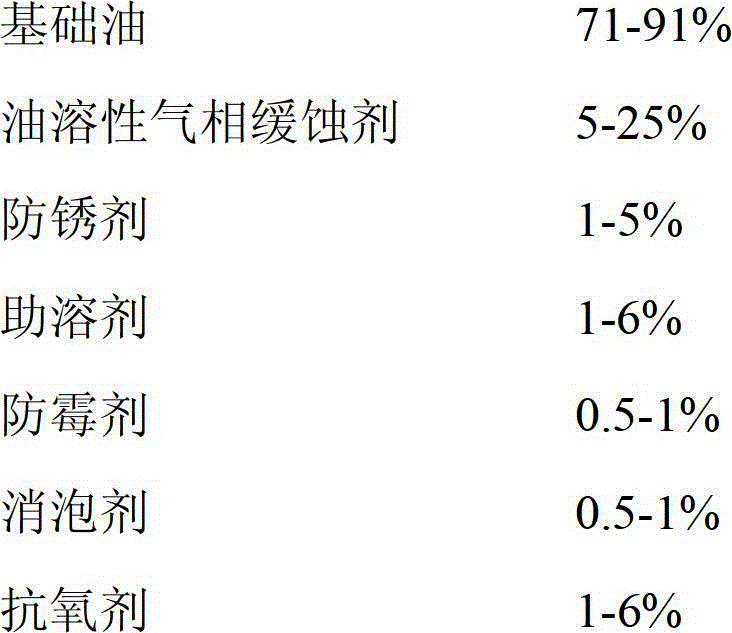

[0020] 1# Vapor-phase anti-rust oil, composed of the following components by weight:

[0021]

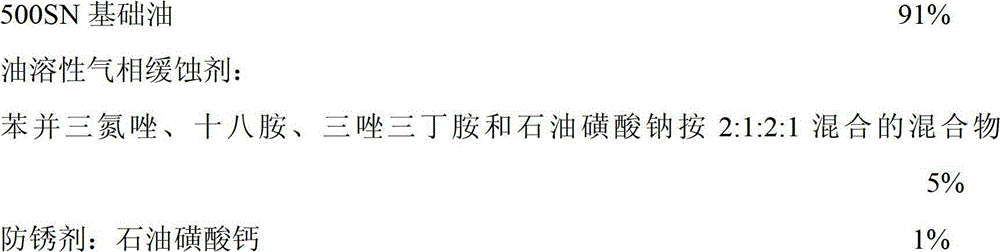

[0022]

[0023] Product preparation method and steps are as follows:

[0024] Raw material components in proportion: 91 parts of 500SN base oil, 5 parts of benzotriazole, tert-butyl chromate, naphthenic acid soap, mixture of sodium petroleum sulfonate, 1 part of calcium petroleum sulfonate, 1 part of benzene Sodium formate, 0.5 part of silicone defoamer, 1 part of thionyl zinc, 0.5 part of phenol.

[0025] Add sodium benzoate to the mixture of benzotriazole, tert-butyl chromate, naphthenic acid soap, and sodium petroleum sulfonate at a temperature lower than 120°C, and heat to dissolve. When benzotriazole, tert-chromic acid After the mixture of butyl ester, naphthenic acid soap and sodium petroleum sulfonate is completely melted, slowly add it into the reaction kettle, stir while adding, and then add calcium petroleum sulfonate, phenol, silicone defoamer and Thiophos-butyloc...

Embodiment 2

[0027] 2# Vapor phase antirust oil consists of the following components by weight:

[0028]

[0029] Prepare each component of raw material according to the above-mentioned ratio, and the preparation method and steps of the product are the same as in Example 1.

Embodiment 3

[0031] 3# Vapor phase antirust oil consists of the following components by weight:

[0032]

[0033]

[0034] Prepare each component of raw material according to the above-mentioned ratio, and the preparation method and steps of the product are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com