Environment-friendly gas-phase rustproof oil and preparation method thereof

A gas-phase rust prevention and environmental protection technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of ineffective rust protection, environmental, soil, human health effects, etc., achieves inhibition of metal corrosion and rust, and is easy to promote Simple effect of application and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

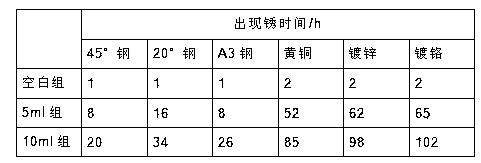

Examples

Embodiment 1

[0016] The environment-friendly vapor phase antirust oil comprises the following raw materials in parts by weight: 100 parts of mineral oil, 8 parts of benzotriazole, 6 parts of cyclohexylamine salicylate, 1 part of sorbitan monooleate, hard 1 part of aluminum fatty acid, 0.5 part of antioxidant BHT, 0.5 part of 10,10'-oxobisphenoxarsenic, 0.5 part of polydimethylsiloxane.

[0017] The preparation method of the environment-friendly vapor-phase antirust oil in this example is: first, put 90 parts of mineral oil into the reaction kettle, heat it to 90°C, keep it warm, and then mix 10 parts of mineral oil, 8 parts of benzene under the condition of lower than 120°C And triazole and 6 parts of cyclohexylamine salicylate were heated to melt, then slowly added to the reaction kettle, and kept stirring, and finally added 1 part of sorbitan monooleate, 1 part of stearin Alumina, 0.5 parts of antioxidant BHT, 0.5 parts of 10,10'-oxobisphenoxarsenic and 0.5 parts of polydimethylsiloxane ...

Embodiment 2

[0020] The environment-friendly vapor phase antirust oil comprises the following raw materials in parts by weight: 120 parts of mineral oil, 15 parts of benzotriazole, 10 parts of cyclohexylamine salicylate, 3 parts of sorbitan monooleate, hard 3 parts of aluminum fatty acid, 6 parts of antioxidant BHT, 1 part of 10,10'-oxobisphenoxarsenic, 1 part of polydimethylsiloxane.

[0021] The preparation method of the environment-friendly gas-phase antirust oil in this example is: first, put 105 parts of mineral oil into the reaction kettle, heat it to 90°C, keep it warm, and then mix 15 parts of mineral oil, 15 parts of benzene under the condition of lower than 120°C And triazole and 10 parts of cyclohexylamine salicylate were heated to melt, then slowly added to the reaction kettle, and kept stirring, and finally added 3 parts of sorbitan monooleate, 3 parts of stearin Alumina, 6 parts of antioxidant BHT, 1 part of 10,10'-oxobisphenoxarsen and 1 part of polydimethylsiloxane were kep...

Embodiment 3

[0024] The environment-friendly vapor phase antirust oil comprises the following raw materials in parts by weight: 110 parts of mineral oil, 12 parts of benzotriazole, 8 parts of cyclohexylamine salicylate, 2 parts of sorbitan monooleate, hard 2 parts of aluminum fatty acid, 3 parts of antioxidant BHT, 0.8 parts of 10,10'-oxobisphenoxarsenic, 0.75 parts of polydimethylsiloxane.

[0025] The preparation method of the environment-friendly vapor-phase antirust oil in this example is: first, put 105 parts of mineral oil into the reaction kettle, heat it to 90°C, keep it warm, and then add 5 parts of mineral oil, 12 parts of benzene under the condition of lower than 120°C And triazole and 8 parts of cyclohexylamine salicylate were heated to melt, then slowly added to the reaction kettle, and kept stirring, and finally added 2 parts of sorbitan monooleate, 2 parts of stearin Alumina, 3 parts of antioxidant BHT, 0.8 part of 10,10'-oxobisphenoxarsen and 0.75 part of polydimethylsiloxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com