Composition for making polyvinyl chloride thermal contraction vapor phase antirust film

A gas-phase anti-rust and polyvinyl chloride technology, applied in the field of gas-phase anti-rust, can solve the problems of low cost of desiccant anti-rust, time-consuming, labor-intensive and unhygienic removal of the protective layer, so as to achieve environmental protection and human health, and realize gas-phase anti-rust Anti-rust requirements, the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

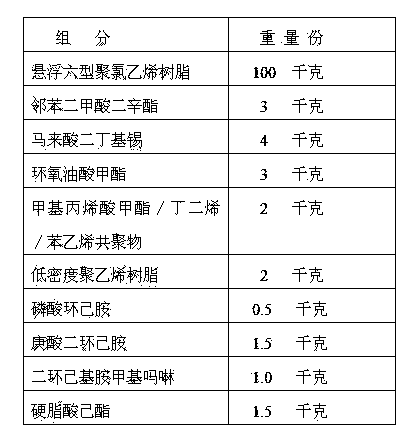

[0020] A composition for preparing polyvinyl chloride heat-shrinkable vapor-phase antirust film comprising suspension type six polyvinyl chloride resin, dioctyl phthalate, dibutyltin maleate, epoxy methyl oleate, methacrylic acid Methyl ester / butadiene / styrene copolymer, low density polyethylene resin, cyclohexylamine phosphate, dicyclohexylamine heptanoate, dicyclohexylamine methylmorpholine and hexyl stearate, each component and its The parts by mass are:

[0021]

[0022] Under stirring conditions, 100 kg of suspended six-type polyvinyl chloride resin, 3 kg of dioctyl phthalate, 4 kg of dibutyltin maleate, 3 kg of epoxy methyl oleate, 2 kg of methacrylic acid Methyl ester / butadiene / styrene copolymer, 2 kg of low density polyethylene resin, 0.5 kg of cyclohexylamine phosphate, 1.5 kg of dicyclohexylamine heptanoate, 1.0 kg of dicyclohexylamine methylmorpholine and 1.5 kg of hard After the hexyl fatty acid is measured, the mixture is mixed and stirred in a high-speed mixe...

Embodiment 2

[0024] A composition for preparing polyvinyl chloride heat-shrinkable vapor-phase antirust film comprising suspension type seven polyvinyl chloride resin, methyl diphenyl phosphate, diisobutyl phthalate, dibutyltin laurate maleate, Epoxy methyl ricinoleate, acrylate copolymer, low-density polyethylene resin, cyclohexylamine phosphate, dicyclohexylamine nonanoate, dimorpholinomethylcyclohexylamine and ethyl stearate, each component and Its mass parts are:

[0025]

[0026] Under stirring conditions, 100 kg of suspended seven-type polyvinyl chloride resin, 3 kg of methyl diphenyl phosphate, 2 kg of diisobutyl phthalate, 3 kg of dibutyltin laurate maleate, 4 kg Epoxy methyl ricinoleate, 1 kg of acrylate copolymer, 3 kg of low density polyethylene resin, 1.0 kg of cyclohexylamine phosphate, 1.3 kg of dicyclohexylamine nonanoate, 1.5 kg of dimorpholinomethylcyclohexylamine and After measuring 1.0 kilogram of ethyl stearate, mix and stir in a high-speed mixer for 40 minutes, sea...

Embodiment 3

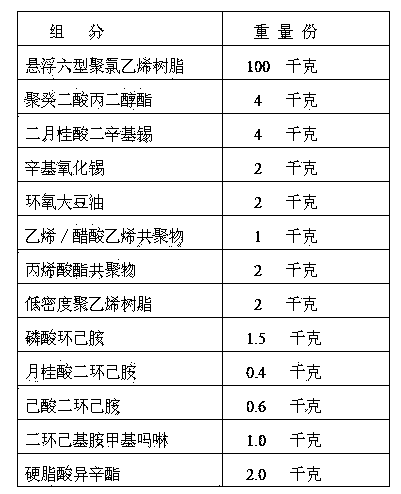

[0028] A composition for preparing polyvinyl chloride heat-shrinkable vapor-phase antirust film comprising suspension type six polyvinyl chloride resin, polypropylene glycol sebacate, dioctyltin dilaurate, octyltin oxide, epoxy soybean oil, ethylene ∕ Vinyl acetate copolymer, acrylate copolymer, low density polyethylene resin, cyclohexylamine phosphate, dicyclohexylamine laurate, dicyclohexylamine caproate, dicyclohexylamine methylmorpholine and isooctyl stearate Ester, each component and mass parts thereof are:

[0029]

[0030] Under the condition of stirring, 100 kilograms of suspended six-type polyvinyl chloride resin, 4 kilograms of polypropylene sebacate, 4 kilograms of dioctyltin dilaurate, 2 kilograms of octyltin oxide, 2 kilograms of epoxy soybean oil, 1 kilogram Kg of ethylene / vinyl acetate copolymer, 2 kg of acrylate copolymer, 2 kg of low-density polyethylene resin, 1.5 kg of cyclohexylamine phosphate, 0.4 kg of dicyclohexylamine laurate, 0.6 kg of dicyclohexyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com