Preparation method and device of rubber vulcanization accelerator DZ

A technology for rubber vulcanization and accelerator, applied in the field of preparation of rubber vulcanization accelerator DZ, can solve the problems of no specific value of yield and low yield, and achieve the effects of stable product quality, improved product yield and stable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

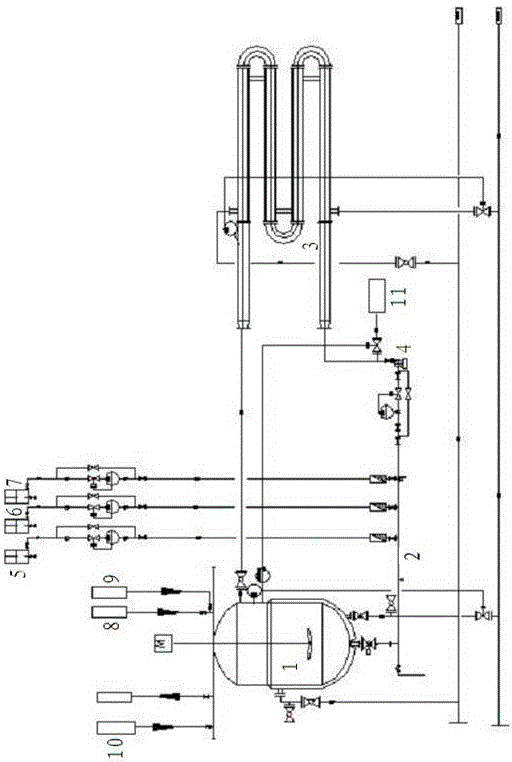

[0027] as attached figure 1 The process shown in : add 400ml of isopropanol and 100g of dicyclohexylamine into the reaction kettle, under the conditions of 40°C and 800r / min, the dicyclohexylamine is fully dissolved in isopropanol, and the pipeline is opened Circulation reactor, start dripping sodium hypochlorite, M-Na salt and dilute sulfuric acid with the flow rate of 14ml / min, 7ml / min, 2ml / min respectively, dropwise time is 1h, control pH value in the process to be 9.0, pump out after the reaction is completed. Filter, wash with water, and dry to obtain accelerator DZ product with a yield of 98.4%.

Embodiment 2

[0029] as attached figure 1 The process shown in : add 400ml of isopropanol and 100g of dicyclohexylamine into the reaction kettle, under the conditions of 40°C and 800r / min, the dicyclohexylamine is fully dissolved in isopropanol, and the pipeline is opened Circulate the reactor, start dripping sodium hypochlorite, M-Na salt and dilute sulfuric acid with the flow rate of 7ml / min, 3.5ml / min, 1ml / min respectively, the dripping time is 2h, control the pH value in the process to be 9.5, after the reaction is completed Suction filtration, washing with water and drying to obtain accelerator DZ product with a yield of 98.7%.

Embodiment 3

[0031] as attached figure 1 The process shown in: Add the mother liquor obtained in Example 2, 200ml of isopropanol and 100g of dicyclohexylamine into the reaction kettle, and fully dissolve the dicyclohexylamine in the isopropanol at 40°C and 800r / min. In propanol, open the pipeline circulation reactor, start dripping sodium hypochlorite, M-Na salt and dilute sulfuric acid at flow rates of 7ml / min, 3.5ml / min, and 1ml / min respectively, and the dropping time is 2h, and the pH value is controlled during the process It was 9.5, and after the reaction was completed, it was suction filtered, washed with water, and dried to obtain the accelerator DZ product with a yield of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com