Catalyst for recycling phenylamine rectification residue and preparation method of catalyst

A catalyst and resource-based technology, applied in catalyst activation/preparation, organic compound preparation, physical/chemical process catalysts, etc., can solve the problems of high catalyst overall cost, short catalyst life, low economy, etc., and achieve industrial application. , the overall economic improvement, the effect of improving the achievability

- Summary

- Abstract

- Description

- Claims

- Application Information

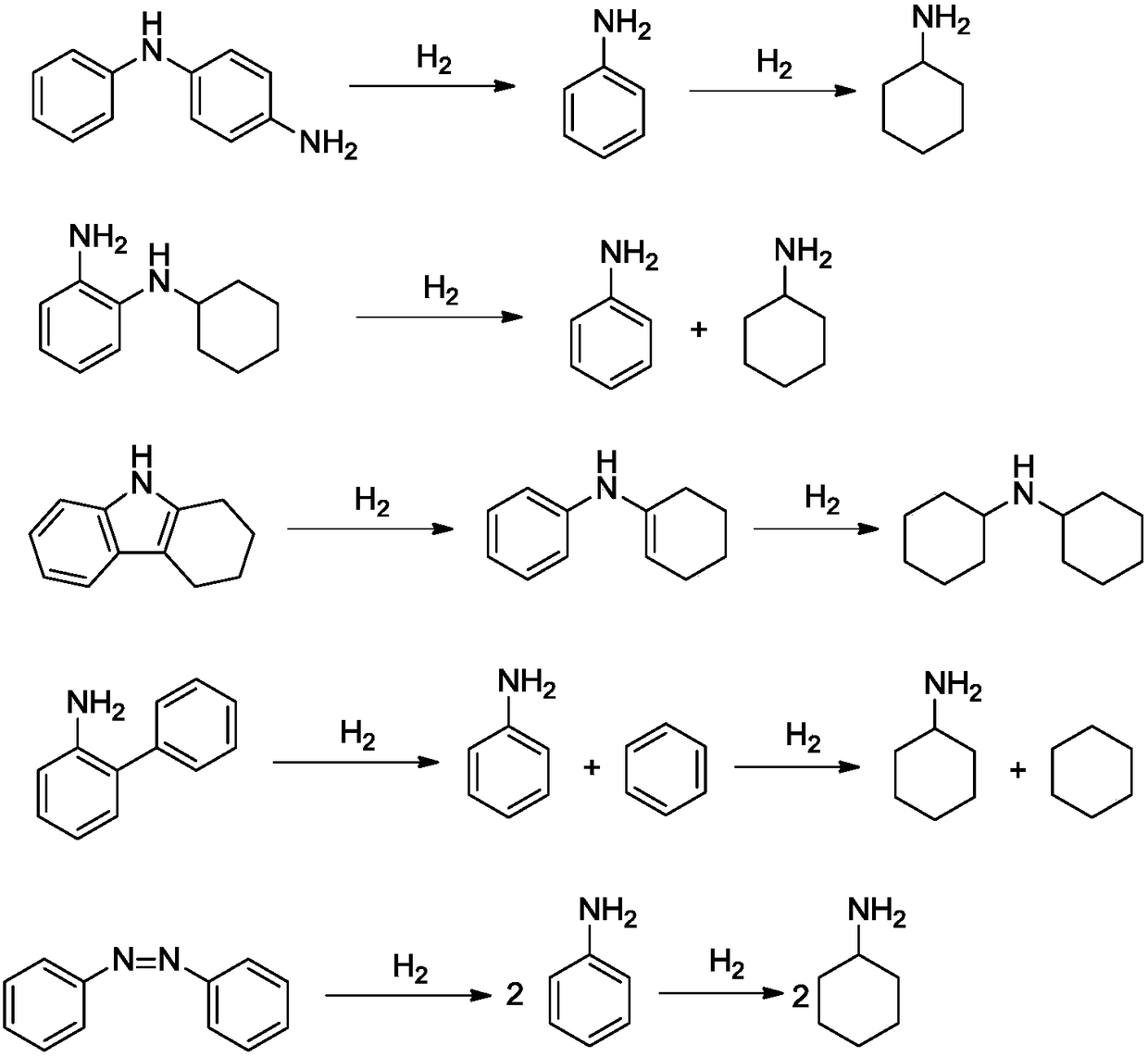

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh each group of medicines according to the ratio shown in Table 1 and dissolve them in distilled water to obtain five groups of solutions with a concentration of about 2.5 mol / L, which are respectively recorded as solutions A1, A2, A3, A4 and A5. Take the sodium hydroxide that concentration is 7.6mol / L again, record as solution B.

[0043] Heat the water in the precipitation tank to 60°C, and then add the solutions A1 and B into the precipitation tank side by side. During the preparation process, the pH value and precipitation temperature were maintained at 6.5-7.5 and 60°C, respectively. After the precipitation is over, keep the stirring speed and precipitation temperature constant, age for 8 hours, filter and wash until neutral, place the precipitate in an oven at 110°C for 12 hours, and after the drying is complete, roast it in an air atmosphere at 400°C for 4 hours, and Crushed and pulverized to 400-600 mesh to obtain magnesia-modified alumina carrier powder D1...

Embodiment 2

[0049] Prepare 80ml of nitrate impregnation solution containing 15g Ni, 0.5g Ru, 0.5g Fe, 1g Mo, 1g Zn, 0.5g Re, 0.5g Ce, pour 81g carrier Z1 into the above impregnation solution, and absorb at room temperature for 2h, the solution Almost completely absorbed. After the above-mentioned adsorbed carrier Z1 is dried, it is calcined at about 475°C for 12 hours, cooled, and then reduced and activated at about 350°C under a reducing atmosphere. , Fe 0.5wt%, Mo 1wt%, Zn1wt%, Re 0.5wt% and Ce 0.5wt% catalyst C1.

[0050] Fill the catalyst C1 with a random volume of 10ml in the fixed-bed reactor; mix liquid ammonia and aniline rectification residue according to the volume ratio of 1:2 to obtain a diluent, adjust the reaction temperature to 150°C, and the system pressure (absolute pressure, The same below) rise to 15MPa and start to feed, diluent space velocity is 0.3h -1 , H 2 The flow rate was 200ml / min, and sampling and analysis began after 10 hours of reaction. The contents of cy...

Embodiment 3

[0052] Prepare 75ml of nitrate impregnation solution containing 10g Ni, 3g Ru, 0.5g Fe, 0.5g Cr, 5g Cu and 5g Zr, pour 76g carrier Z1 into the above impregnation solution, and absorb for 2 hours at room temperature, the solution is basically completely absorbed. After the above-mentioned adsorbed carrier Z1 is dried, it is calcined at about 500°C for 10 hours, cooled, and then reduced and activated at about 400°C under a reducing atmosphere. Catalyst C2 with Cr 1 wt%, Cu 5 wt% and Zr 5 wt%.

[0053] Fill the catalyst C2 with a random volume of 10ml in the fixed-bed reactor; mix methylamine and aniline rectification residue according to the volume ratio of 1:1 to obtain a diluent, adjust the reaction temperature to 200 ° C, and the system pressure (absolute pressure, The same below) rise to 15MPa and start to feed, diluent space velocity is 1.0h -1 , H 2 The flow rate was 300ml / min, and sampling and analysis began after 10 hours of reaction. The contents of cyclohexylamine an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com