Corrosion-resistant anti-rust oil

A technology of anti-rust oil and corrosion resistance, applied in the field of lubricating oil, can solve the problems of affecting the lubrication effect and unreachable performance, and achieve the effect of good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

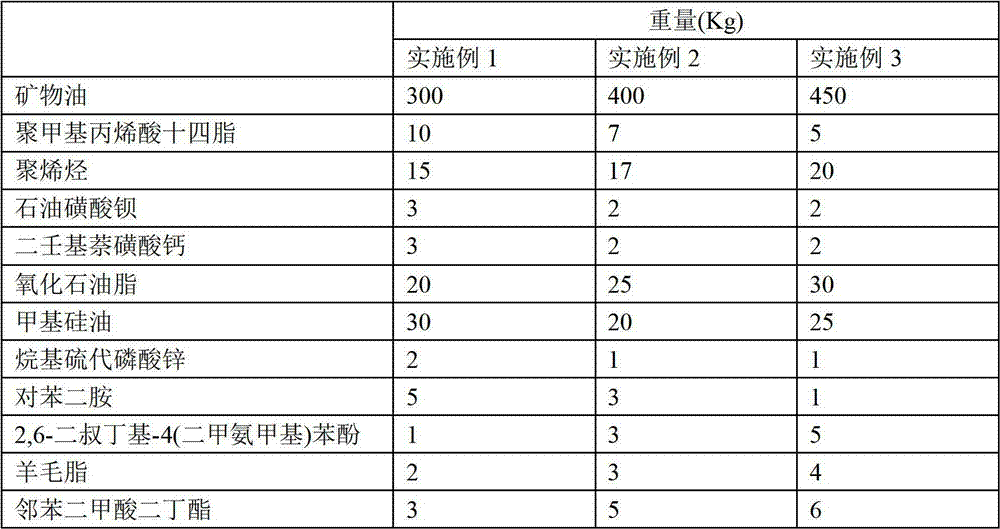

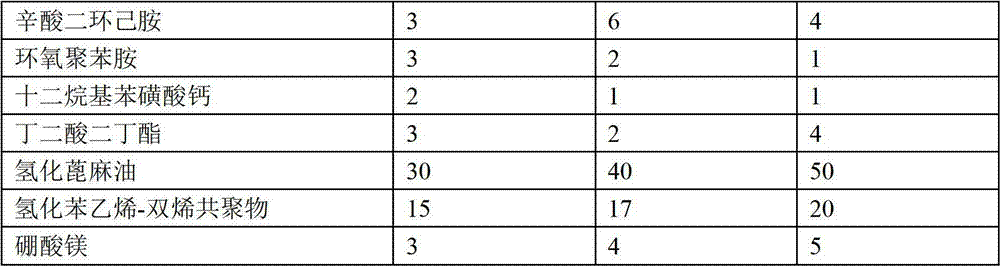

Embodiment 1

[0023] S1: Add mineral oil into the reaction kettle, and heat up to 120°C while stirring;

[0024] S2: Add polytetradecyl methacrylate, polyolefin, barium petroleum sulfonate, calcium dinonylnaphthalene sulfonate, oxidized petroleum grease, methyl silicone oil, zinc alkylthiophosphate, p-phenylenediamine, 2,6-di-tert-butyl-4(dimethylaminomethyl)phenol, lanolin, dibutyl phthalate, dicyclohexylamine octanoate, epoxy polyaniline, calcium dodecylbenzenesulfonate, Dibutyl succinate, stirred for 2h;

[0025] S3: Cool down to 40°C, add hydrogenated castor oil, hydrogenated styrene-diene copolymer, and magnesium borate while stirring, continue stirring for 2 hours, and filter to obtain.

Embodiment 2

[0027] The difference from Example 1 is: the temperature in step S1 is 125° C.; the stirring time in step S2 is 2.5 h; the temperature in step S3 is 45° C. and the stirring time is 2.5 h.

Embodiment 3

[0029] The difference from Example 1 is: the temperature in step S1 is 130° C.; the stirring time in step S2 is 3 h; the temperature in step S3 is 50° C. and the stirring time is 3 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com