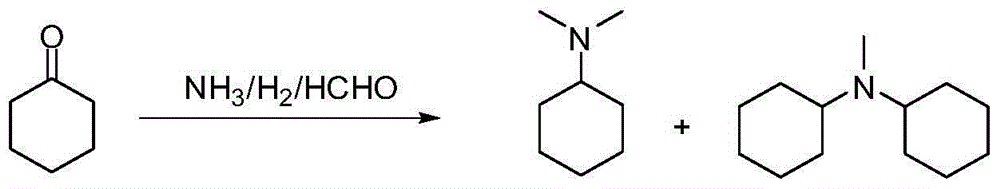

Method for preparing N,N-dimethylcyclohexylamine and N-methyl-dicyclohexylamine

A technology of methyldicyclohexylamine and dimethylcyclohexylamine, which is applied in the field of preparing polyurethane catalysts, can solve problems such as poor selectivity, low product yield, and harmful environment, and achieve low production cost, high product yield, High conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

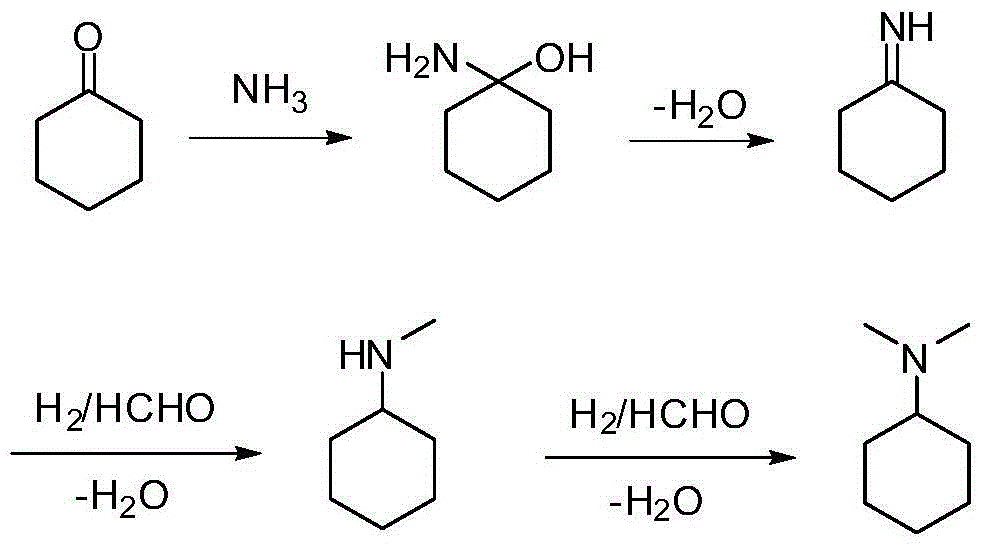

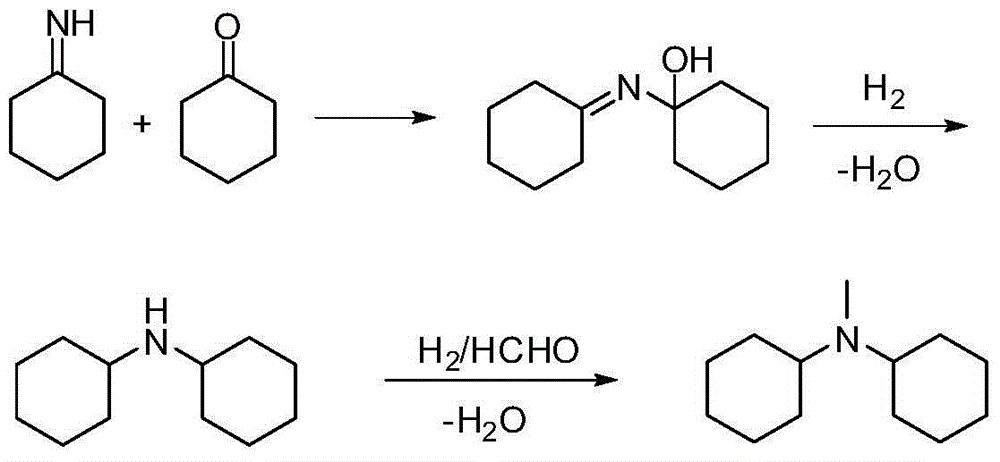

Method used

Image

Examples

Embodiment 1

[0041] Preparation of 1# nickel-based catalyst:

[0042] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 250m 2 / g, pore volume 0.45cc / g) was calcined at 450°C for 4h. Dissolve 123.88g of nickel nitrate hexahydrate, 19.23g of chromium nitrate nonahydrate, and 1.91g of copper nitrate trihydrate in 500ml of deionized water, heat to 80°C to form a homogeneous solution, and then add 472g of γ-Al 2 o 3 Carrier, rotate and dip in a water bath at 80°C for 4 hours, then gradually evaporate to dryness, bake in an oven at 120°C for 12 hours; finally move to a muffle furnace, heat up to 500°C in an air atmosphere at 2-3°C / min for 6 Hours, the catalyst can be obtained after natural cooling. The composition of the catalyst is: Ni is 5wt%, Cr is 0.5wt%, Cu is 0.1wt%, and the rest is γ-Al 2 o 3 , based on the corresponding metal element in the total mass of the catalyst.

Embodiment 2

[0044] Preparation of 2# cobalt catalyst:

[0045] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 250m 2 / g, pore volume 0.45cc / g) was calcined at 450°C for 4h. Dissolve 123.47g of cobalt nitrate hexahydrate, 6.47g of potassium nitrate, and 0.92g of ammonium heptamolybdate tetrahydrate in 500ml of deionized water, heat to 80°C to form a homogeneous solution, and then add 472.0g of γ-Al 2 o 3 Carrier, rotate and dip in a water bath at 80°C for 4 hours, then gradually evaporate to dryness, bake in an oven at 120°C for 12 hours; finally move to a muffle furnace, heat up to 500°C in an air atmosphere at 2-3°C / min for 6 Hours, the catalyst can be obtained after natural cooling. The composition of the catalyst is: Co is 5.0wt%, K is 0.5wt%, Mo is 0.1wt%, and the rest is γ-Al 2 o 3 , based on the corresponding metal element in the total mass of the catalyst.

Embodiment 3

[0047] Preparation of 3# nickel-based catalyst:

[0048] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 250m 2 / g, pore volume 0.45cc / g) was calcined at 450°C for 4h. Dissolve 247.75g of nickel nitrate hexahydrate, 19.23g of chromium nitrate nonahydrate, and 22.75g of zinc nitrate hexahydrate in 800ml of deionized water, heat to 80°C to form a homogeneous solution, and then add 442.5g of γ-Al 2 o 3 Carriers were rotated and dipped in a water bath at 80°C for 4 hours, then evaporated to dryness gradually, and baked in an oven at 120°C for 12 hours; finally moved to a muffle furnace, and were heated to 500°C in an air atmosphere at 2-3°C / min for 8 Hours, the catalyst can be obtained after natural cooling. The composition of the catalyst is: Ni is 10wt%, Cr is 0.5wt%, Zn is 1wt%, and the rest is γ-Al 2 o 3 , based on the corresponding metal element in the total mass of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com