Combined coal tar whole fraction hydroprocessing system and application thereof

A technology for hydrotreating and coal tar, applied in the field of coal tar whole fraction treatment process, can solve the problems of loss of effect, inability to achieve deep desalination, dehydration, slag removal, acid catalyst poisoning damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

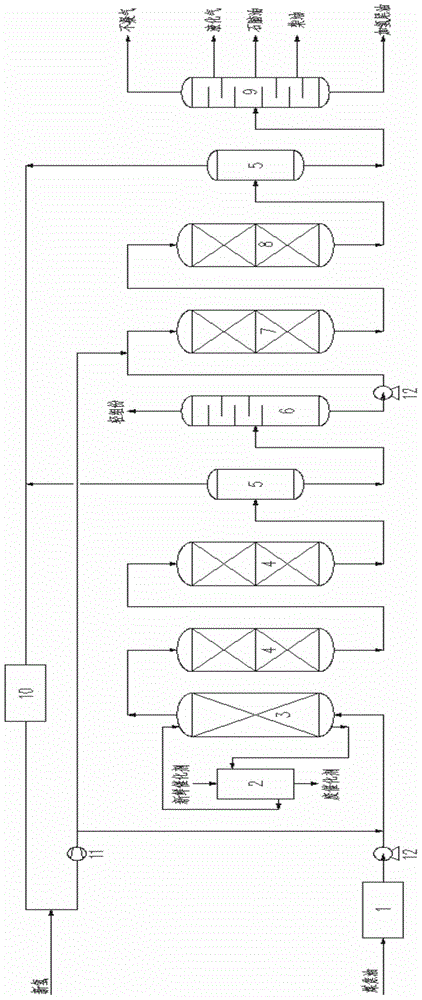

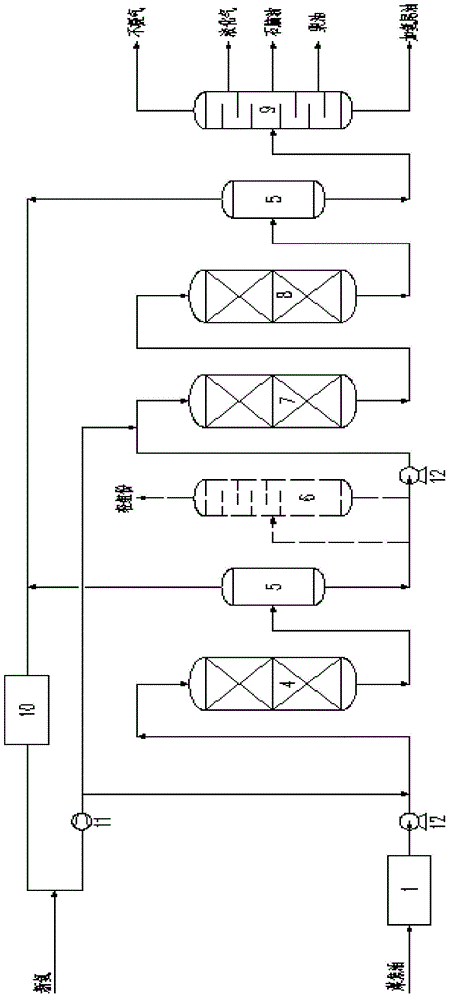

[0091] Example 1: Device

[0092] The desalination, dehydration, and impurity removal refining system 1 is connected to the hydrogen compressor 11 and the upflow moving bed hydrofining reactor 3 respectively through the hydrogenation feed pump 12, and the latter is connected to the catalyst online feeding system 2, two fixed bed reactors connected in series The hydrogen refining reactors 4 are connected respectively, and the fixed bed hydrotreating reactor 4 is connected with the separator 5, and the separator 5 is connected with the hydrogen refining system 10 and the flash tower 6 respectively, and the flash tower 6 is connected with the hydrogenation feed pump 12 and The fixed-bed hydrocracking reactor 7 is connected, and then connected with the fixed-bed hydrotreating reactor 8, the separator 5, and the fractionation tower 9 in sequence, wherein:

[0093] The new hydrogen is connected to the pipeline connecting the hydrogenation feed pump 12 and 3 through the hydrogen refi...

Embodiment 2

[0096] The upflow moving bed hydrofinishing reactor, fixed bed hydrocracking and fixed bed hydrofinishing combination process of the present invention can produce high-quality naphtha and diesel components, and other performance indexes all meet national standards.

[0097] Its principle process flow diagram ( figure 1 ):

[0098] 1. Desalination, dehydration, and impurity removal treatment: Add diluent aromatic solvent oil and demulsifier alkylene oxide to the whole fraction of coal tar, and then go through desalination, dehydration, and impurity removal refining system 1. The refined coal tar salt content is less than 5mg / L. The water content is less than 4%.

[0099] The amount of diluent to be added is based on the viscosity of coal tar, and the viscosity of coal tar is controlled at 20mm.s -2 (100 DEG C), the diluent used in this embodiment adopts the mixed xylene produced by the petrochemical factory as the diluent, the content of aromatics is more than 90%, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com